High polymer material compounded plate type solar heat collector and core veneer manufacturing method thereof

A technology of solar heat collectors and polymer materials, applied in the direction of solar heat collectors, solar heat collectors using working fluids, solar heat collector components, etc., can solve the problem that sunlight cannot be selectively absorbed, etc. Achieve the effect of solving complex manufacturing process, light weight and increased heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

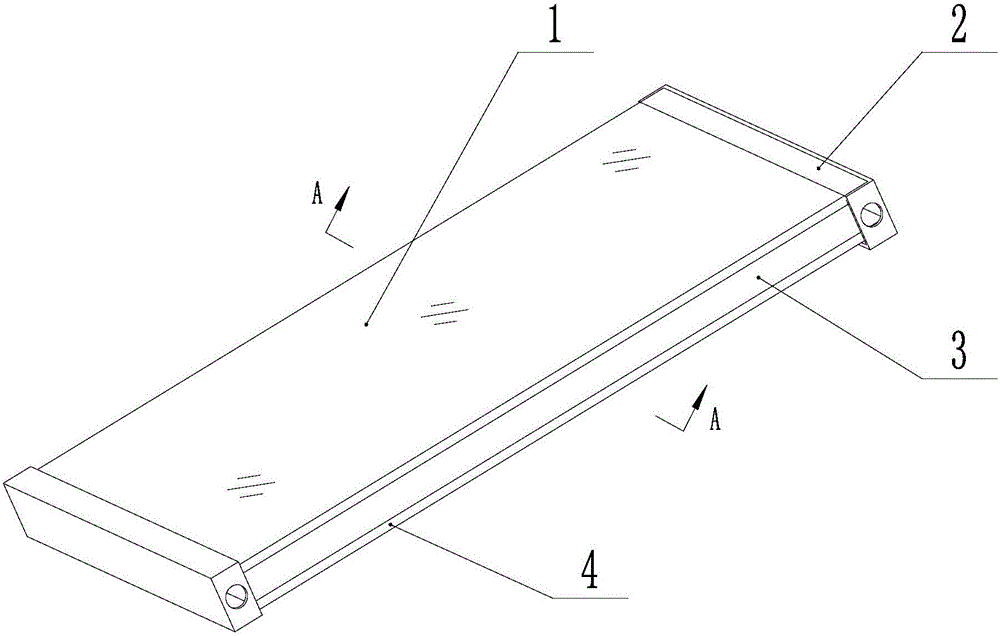

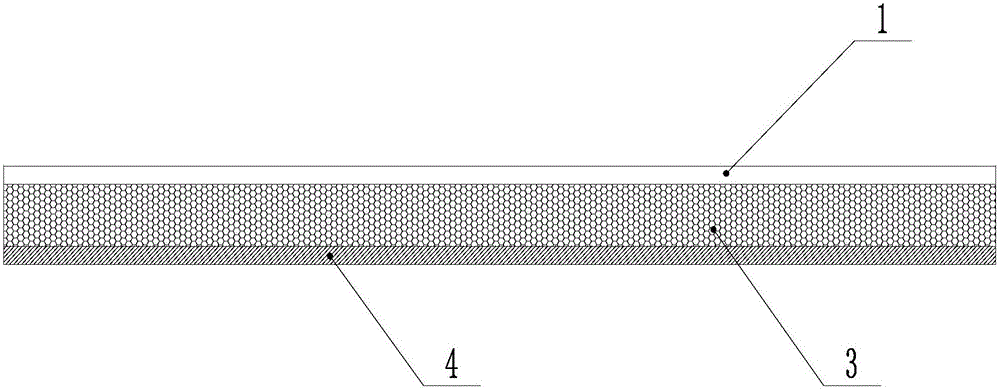

[0029] A kind of plate type solar heat collector of present embodiment composite polymer material, as figure 1 or figure 2 As shown, the plate solar collector is made of polymer materials, including the solar heat absorbing core plate 3, the transparent cover plate 1, the opaque bottom plate 4 and the end sealing beam 2, wherein the transparent cover plate is compounded on the solar heat absorbing core plate At the top, the opaque bottom plate is compounded under the solar heat-absorbing core plate, and the end-sealed beam is compounded on the longitudinal end faces of the solar heat-absorbing core plate, transparent cover plate and opaque bottom plate, sealing the solar heat-absorbing core plate, transparent cover plate and opaque bottom plate vertical space.

[0030] Among them, the manufacturing method of the solar heat absorbing core board is: using a mixing and extruding equipment with a strong mixing and dispersing effect (such as a blade extruder or an eccentric rotor...

Embodiment 2

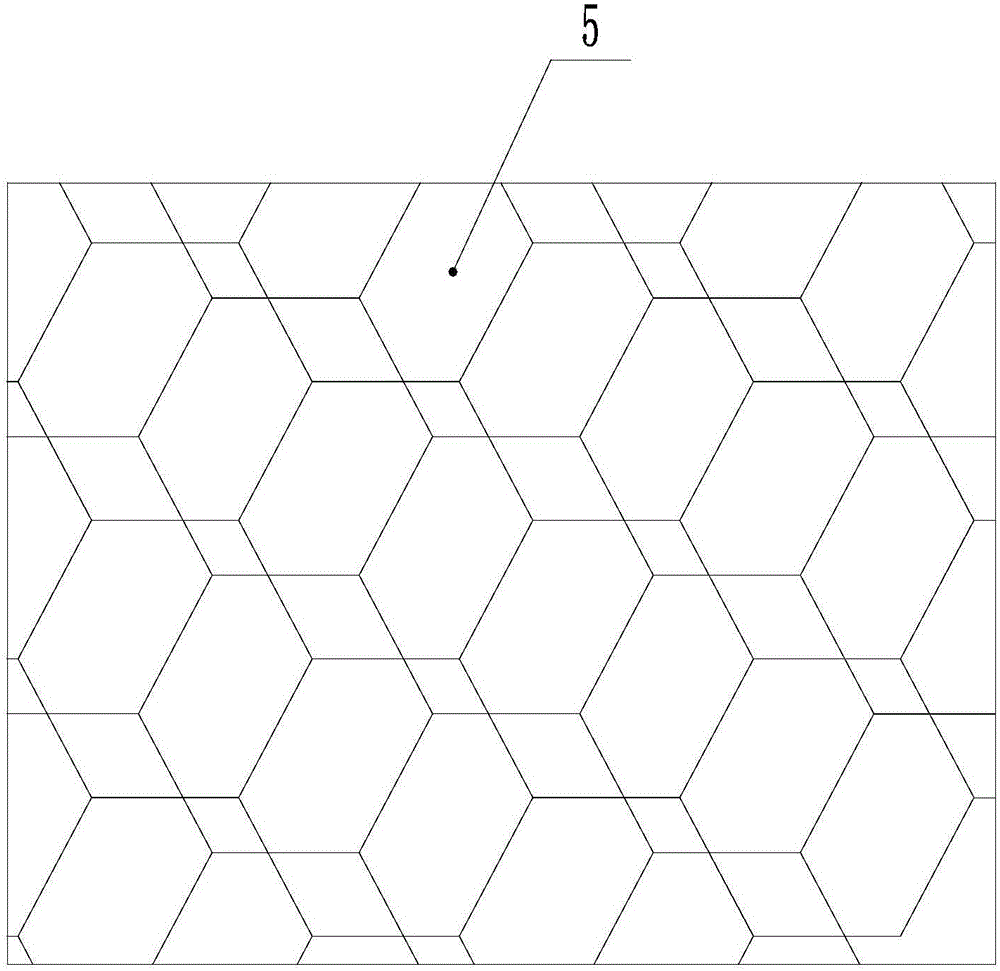

[0038] In this embodiment, a kind of polymer material composite plate solar heat collector is compared with Embodiment 1, and its difference is that: the solar heat absorbing core plate is a hollow plate with a longitudinal medium channel (such as Figure 4 shown), the manufacturing method is: using a mixing and extruding equipment with a strong mixing and dispersing effect (such as a blade extruder or an eccentric rotor extruder, etc.) A polymer material that selectively absorbs solar energy is made in the matrix (the mass content of the solar selective absorber in the polymer is generally about 0.01% to 30%), and then manufactured by extrusion, injection molding, etc. into a hollow sheet with longitudinal media channels 6. The longitudinal media channel can be one or more layers, and the cross section of the longitudinal media channel can be circular, rectangular, honeycomb or other shapes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com