Preparation method of organic electroluminescence device

An electroluminescence device and luminescence technology, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of sunlight loss, device luminous efficiency reduction, high light absorption rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

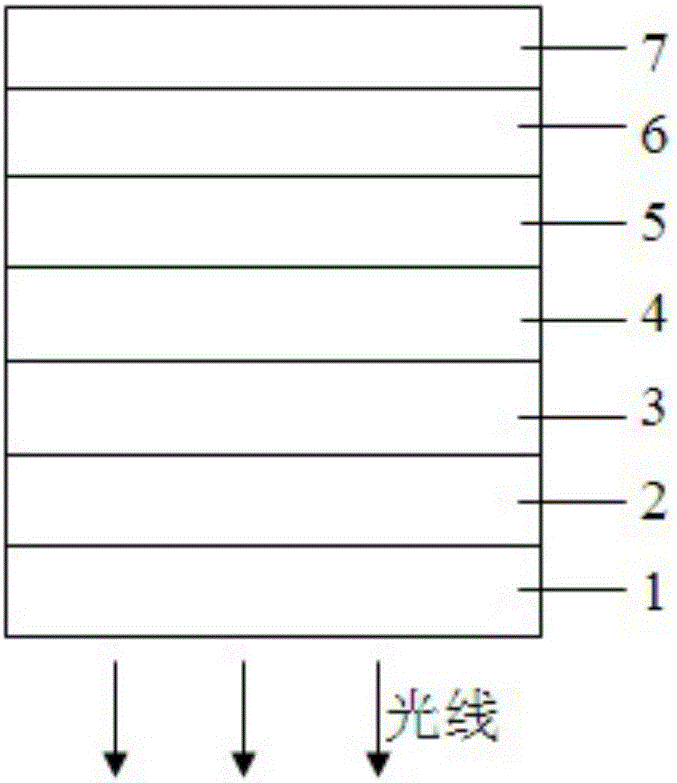

[0065] An organic electroluminescent device, the preparation method comprising the following steps:

[0066] (1) First, the size is 2 × 2cm 2 The ITO glass was cleaned by ultrasonic cleaning with detergent and deionized water for 15min in turn to remove organic pollutants on the surface. The thickness of the ITO layer of the ITO glass was 180nm;

[0067] The hole injection layer was prepared by spin coating on the ITO glass, and the specific operation was as follows: according to Re 2 O 7 : AIBA: ZnO: polytetrafluoroethylene (PTFE): water in a weight ratio of 30: 15: 1: 2: 100, the Re 2 O 7 , AIBA, ZnO, and polytetrafluoroethylene (PTFE) are added to water and mixed evenly to obtain a mixture. The particle size of ZnO is 50 nm, and the polytetrafluoroethylene (PTFE) is a DuPont product, model TE3885; on ITO glass at 4000 rpm The mixture was spin-coated at a rate of 10 s, and then dried at 100° C. for 25 min to obtain a hole injection layer with a thickness of 80 nm;

[00...

Embodiment 2

[0078] An organic electroluminescent device, the preparation method comprising the following steps:

[0079] (1) First, the size is 2 × 2cm 2 The AZO glass was cleaned with detergent and deionized water by ultrasonic cleaning for 15min in turn to remove organic pollutants on the surface. The thickness of the AZO layer of the AZO glass was 80nm;

[0080] The hole injection layer was prepared by spin coating on AZO glass. The specific operation was as follows: according to ReO 2 : AIBI: ZnO: polytetrafluoroethylene (PTFE): ethanol in a weight ratio of 10: 2: 0.5: 0.5: 100, the ReO 2 , AIBI, ZnO and polytetrafluoroethylene (PTFE) are added to ethanol and mixed uniformly to obtain a mixture, the particle size of ZnO is 20nm, and the polytetrafluoroethylene (PTFE) is a DuPont product, model TE3885; on AZO glass at 500rpm The mixture was spin-coated at a speed of 5 s, and then dried at 200 °C for 10 min to obtain a hole injection layer with a thickness of 100 nm;

[0081] (2) The...

Embodiment 3

[0090] An organic electroluminescent device, the preparation method comprising the following steps:

[0091] (1) First, the size is 2 × 2cm 2 The IZO glass was cleaned by ultrasonic cleaning with detergent and deionized water for 15min in turn to remove organic pollutants on the surface. The thickness of the IZO layer of the IZO glass was 100nm;

[0092] The hole injection layer was prepared by spin coating on the IZO glass. The specific operation was as follows: according to Re 2 O 3 The weight ratio of: V30: ZnO: polytetrafluoroethylene (PTFE): isopropanol is 60: 20: 10: 5: 100, the Re 2 O 3 , V30, ZnO and polytetrafluoroethylene (PTFE) are added to isopropanol and mixed evenly to obtain a mixture, the particle size of ZnO is 200nm, and the polytetrafluoroethylene (PTFE) is a DuPont product, the model is TE3885;

[0093] The mixture was spin-coated at a speed of 6000 rpm on IZO glass for 30 s, and then dried at 50° C. for 30 min to obtain a hole injection layer with a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com