Selective hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst and selectivity technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve problems such as poor selectivity and short life, and achieve extended The effect of long life, strong anti-gelation ability and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

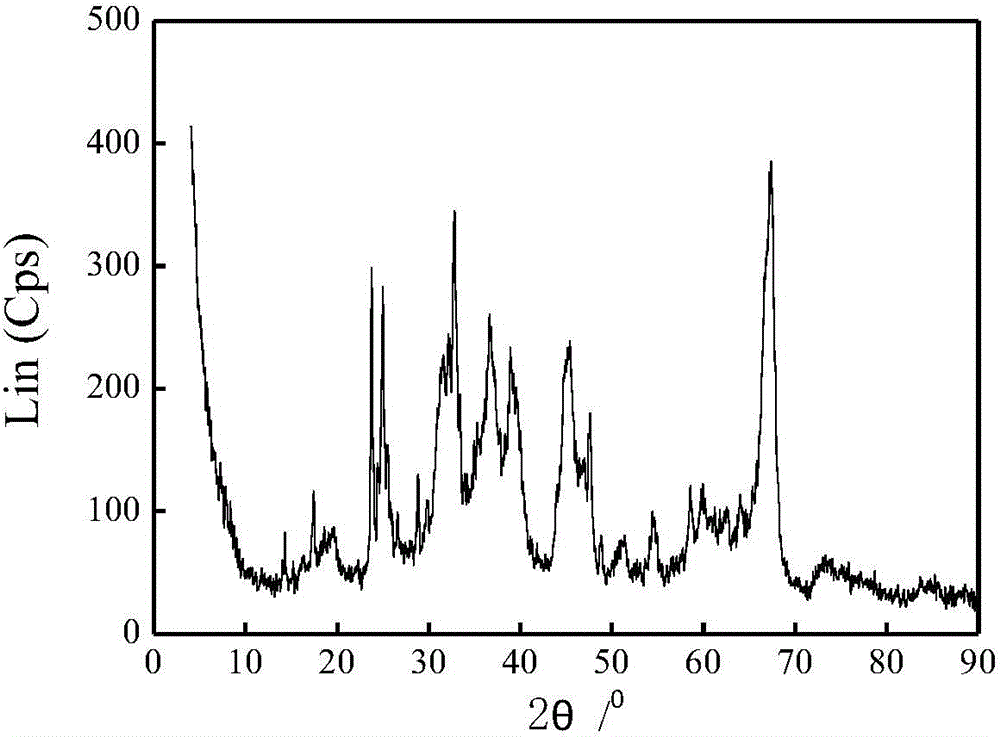

Image

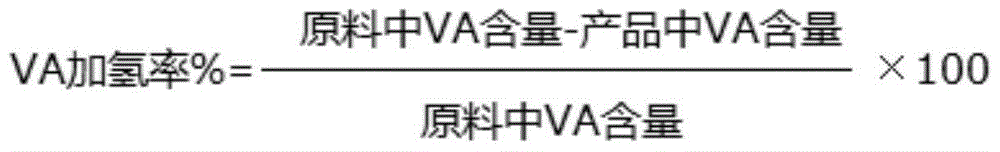

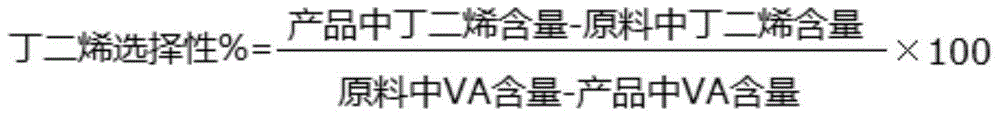

Examples

Embodiment 1

[0057] Mix and knead pseudo-boehmite, niobium pentoxide, nitric acid, and water, extrude into strips, dry at 120°C, and roast at 950°C for 3 hours to obtain a catalyst carrier; then prepare palladium nitrate solution, adjust the pH value to 3.0 with ammonia water, Immerse on the catalyst carrier, remove the remaining liquid after 20 minutes, wash with distilled water, age, dry at 120°C for 2 hours, and roast at 400°C for 3 hours to obtain a palladium-containing catalyst precursor; finally prepare a lead acetate solution and impregnate it on the catalyst precursor , dried at 120°C for 4h, and calcined at 500°C for 4h to prepare the desired catalyst C-1.

Embodiment 2

[0059] Mix and knead pseudo-boehmite, niobium oxalate, nitric acid, and water, extrude, dry at 120°C, and roast at 1000°C for 3 hours to obtain a catalyst carrier; then prepare a palladium chloride solution, adjust the pH to 2.8 with sodium carbonate, and impregnate Put it on the catalyst carrier, remove the remaining liquid after 20 minutes, wash with distilled water, age, dry at 120°C for 2 hours, and roast at 450°C for 3 hours to obtain a palladium-containing catalyst precursor; then prepare a lead nitrate solution and impregnate it in front of the palladium-containing catalyst On the body, it was dried at 120°C for 2h and calcined at 450°C for 4h to prepare the desired catalyst C-2.

Embodiment 3

[0061] Pseudoboehmite, niobium oxalate, nitric acid, and water were mixed and kneaded, extruded, dried at 120°C, and calcined at 500°C for 3 hours to obtain a composite carrier of niobium oxide and alumina; then a certain amount of magnesium nitrate solution was impregnated in the catalyst On the carrier, dry at 110°C for 4 hours and roast at 1080°C for 5 hours to make a catalyst carrier containing magnesium; then prepare a palladium acetate solution, adjust the pH to 3.0 with sodium carbonate, impregnate it on the catalyst carrier, remove the remaining liquid after 20 minutes, and wash with distilled water , after aging, drying at 120°C for 3 hours, and roasting at 420°C for 3 hours to obtain a palladium-containing catalyst precursor; then prepare a lead nitrate solution, impregnate it on the palladium-containing catalyst precursor, dry at 120°C for 3 hours, and roast at 500°C for 4 hours to obtain Desired Catalyst C-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com