Ultrafiltration anti-microbial activated carbon bar and preparation method thereof

A technology of activated carbon and activated carbon powder, which is applied in chemical instruments and methods, filtration treatment, sterilization/microdynamic water/sewage treatment, etc. and other problems, to achieve the effect of improving filtration precision and antibacterial efficiency, good residual chlorine removal efficiency, and rich spatial network structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the preparation of ultrafiltration antibacterial activated carbon rod B1

[0024] Respectively 90 grams of 80-150 mesh, 90 grams of 150-250 mesh, and 30 grams of 150-250 mesh nano zinc oxide composite antibacterial active carbon powder (produced by Huizhou Yinjia Environmental Protection Technology Co., Ltd., zinc oxide weight content is 0.1%) and 90 grams of LDPE binder were placed in a mixing tank and stirred evenly, and the mixture powder was added to a grinding tool and compacted by a compactor, baked at 170°C for 2 hours, demolded and cut to obtain ultra-filtration antibacterial activated carbon Rod B1 (dimensions: outer diameter = 63mm, inner diameter = 35mm, length = 240mm).

Embodiment 2

[0027] Embodiment 2: the preparation of ultrafiltration antibacterial activated carbon rod B2

[0028] Respectively 90 grams of 80-150 mesh, 110 grams of 150-250 mesh, and 40 grams of 150-250 mesh nano zinc oxide composite antibacterial active carbon powder (produced by Huizhou Yinjia Environmental Protection Technology Co., Ltd., zinc oxide weight content is 0.3%) and 60 grams of LDPE polymer binder were placed in a mixing tank and stirred evenly, the mixture powder was added to the abrasive tool and compacted by a compactor, baked at 190°C for 2 hours, demolded and cut to obtain ultrafiltration Antibacterial activated carbon rod B2 (dimensions: outer diameter = 63mm, inner diameter = 35mm, length = 240mm).

Embodiment 3

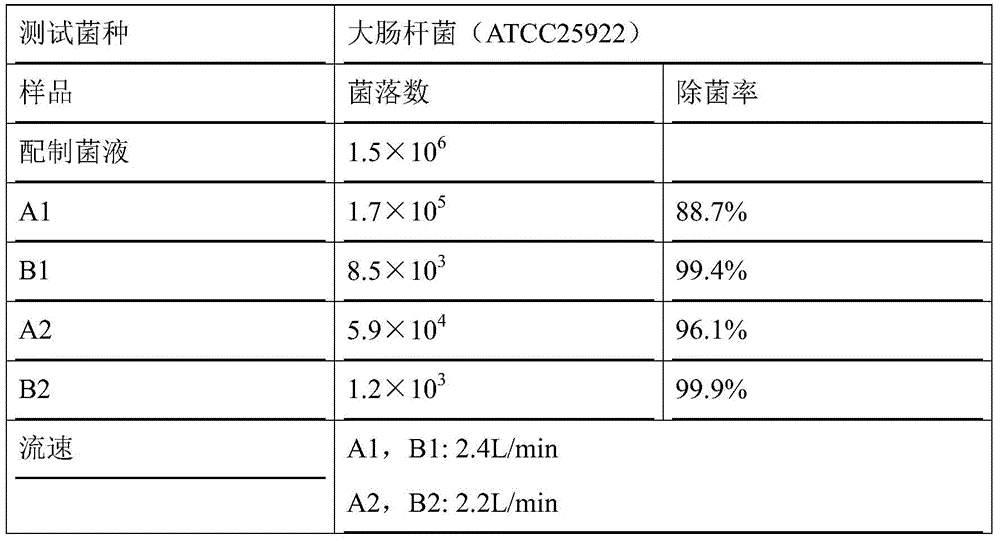

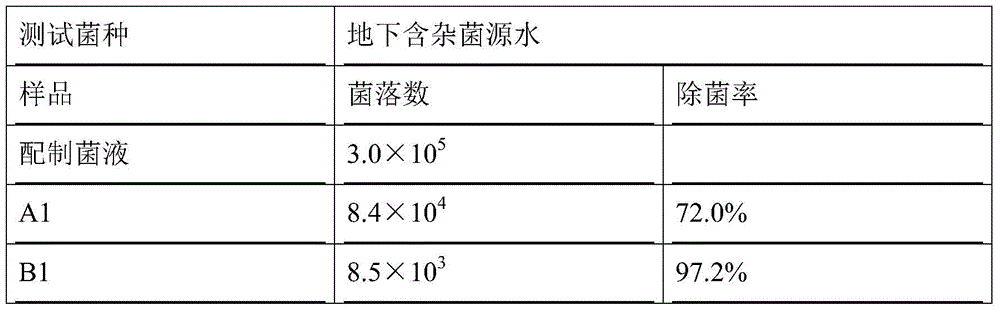

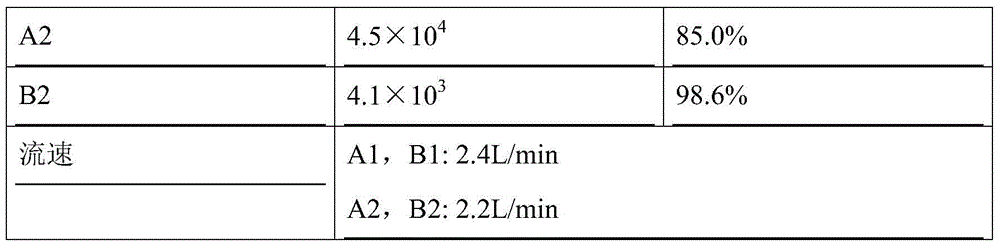

[0031] Embodiment 3: the pore size analysis of A1, A2 and B1, B2

[0032] Utilize stomatometer to analyze the pore size of ultrafiltration activated carbon rod A1, A2 and ultrafiltration antibacterial activated carbon rod B1, B2 in embodiment 1, 2, collect data, A1: 0.4um, B1: 0.4um; A2: 0.2um, B2 :0.2um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com