Wet-process firing method of ceramsite by using cow dung

A technology of cow dung and ceramsite, which is applied in the fields of application, clay products, ceramic products, etc., can solve the problems of complex preparation methods, low compressive strength, and high ceramsite density, and achieve simple preparation methods, low cost, and smooth shapes. The effect of uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

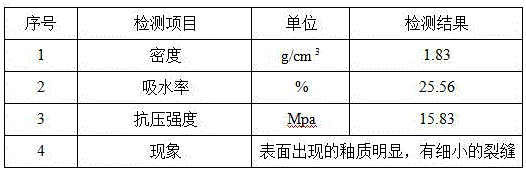

Embodiment 1

[0012] Embodiment 1: a kind of method of firing ceramsite with cow dung dry method, the concrete steps of the method for described ceramsite firing with cow dung dry method are as follows:

[0013] Step1, mixing materials; add auxiliary material cow dung to the main material bentonite to form a material, the material includes bentonite, cow dung, bentonite, cow dung are stirred and mixed in a ratio of 4:1 by weight, and 80 parts of bentonite, cow dung can be selected. 20 parts of dung, stirred and mixed; the cow dung used is the discarded cow dung from the cattle farm, the cow dung was dried at 100 ° C, then pulverized with a pulverizer, and then screened with a sieve to obtain cow dung with a particle size of 80 mesh;

[0014] Step2, granulation; the mixed material is compressed into a powder tablet press, the molding pressure is 6.5Mpa, the holding time is 35s, and it is pressed into a cylinder with a diameter of 30mm and a height of 10mm;

[0015] Step3, pretreatment: put t...

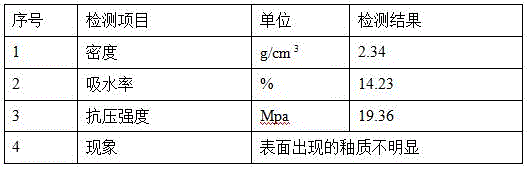

Embodiment 2

[0022] Embodiment 2: a kind of method of firing ceramsite with cow dung dry method, the concrete steps of the method for described ceramsite firing with cow dung dry method are as follows:

[0023] Step1, mixing materials; add auxiliary material cow dung to the main material bentonite to form a material, the material includes bentonite, cow dung, bentonite, cow dung are stirred and mixed in a ratio of 4:1 by weight, and 80 parts of bentonite, cow dung can be selected. 20 parts of dung, stirred and mixed; the cow dung used is the discarded cow dung from the cattle farm, the cow dung was dried at 110 ° C, then pulverized with a pulverizer, and then screened with a sieve to obtain cow dung with a particle size of 100 mesh;

[0024] Step2, granulation; the mixed material is compressed into a powder tablet press, the molding pressure is 7.5Mpa, the holding time is 20s, and it is pressed into a cylinder with a diameter of 30mm and a height of 10mm;

[0025] Step3, pretreatment: put ...

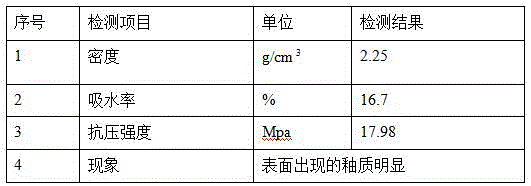

Embodiment 3

[0032] Embodiment 3: a kind of method of firing ceramsite with cow dung dry method, the concrete steps of the method for described ceramsite firing with cow dung dry method are as follows:

[0033] Step1, mixing materials; add auxiliary material cow dung to the main material bentonite to form a material, the material includes bentonite, cow dung, bentonite, cow dung are stirred and mixed in a ratio of 4:1 by weight, and 80 parts of bentonite, cow dung can be selected. 20 parts of dung, stirred and mixed; the cow dung used is the discarded cow dung from the cattle farm, the cow dung was dried at 110 ° C, then pulverized with a pulverizer, and then screened with a sieve to obtain cow dung with a particle size of 120 mesh;

[0034] Step2, granulation; the mixed material is compressed into a powder tablet press, the molding pressure is 8.0Mpa, the holding time is 30s, and it is pressed into a cylinder with a diameter of 30mm and a height of 10mm;

[0035] Step3, pretreatment; put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com