Diffuse reflection material, diffuse reflection layer, wavelength conversion apparatus and light source system

一种波长转换装置、漫反射层的技术,应用在漫反射层,漫反射材料,波长转换装置,光源系统领域,能够解决发光稳定性不好等问题,达到兼顾光效和热稳定性、增强导热作用、提升发光稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

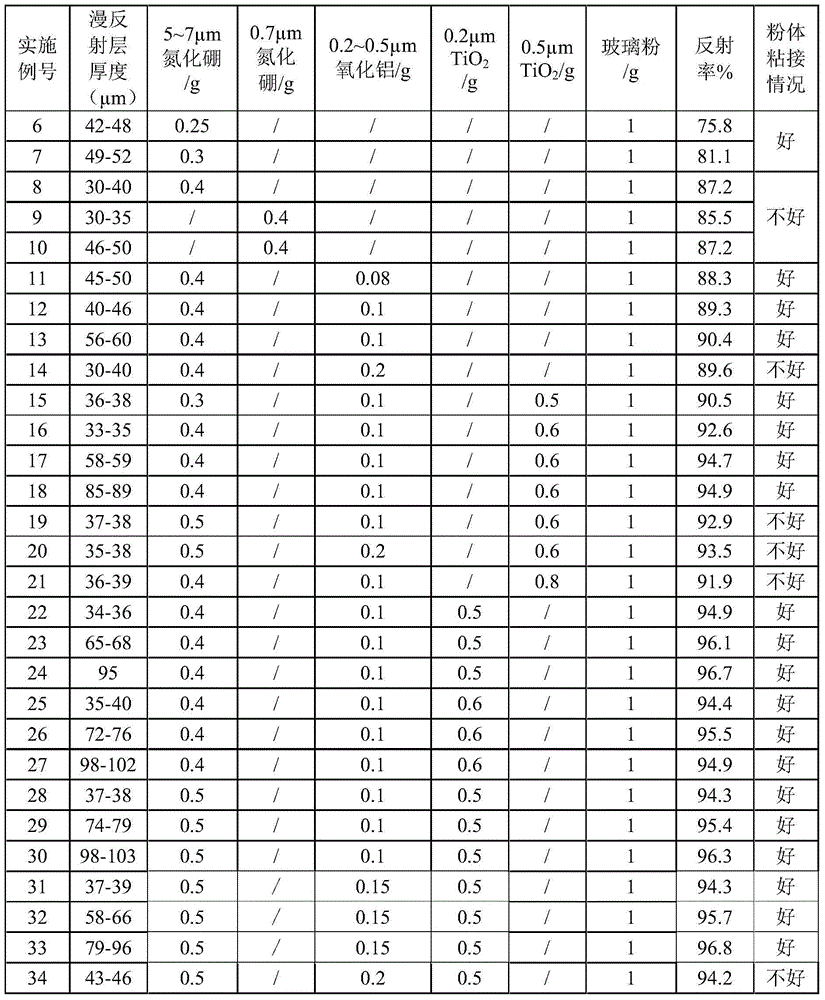

[0039] The above-mentioned diffuse reflection layer can be prepared by using the existing technology. In a preferred embodiment of the present invention, the preparation method of the above-mentioned diffuse reflection layer includes the following steps: high-reflection scattering particles with a whiteness greater than 90, high-refraction scattering particles Particles, high thermal conductivity scattering particles, binder and organic carrier are mixed to form a mixed material; the mixed material is coated on the surface of the substrate and sintered to form a diffuse reflection layer. Preferably, the above coating step adopts the method of scraping coating, spin coating or screen printing, wherein the method of scraping coating is preferably used. The scraping method is beneficial to improve the orientation of flake scattering particles, increase the contact area between particles, and then improve the thermal conductivity. Preferably, in the above-mentioned sintering step ...

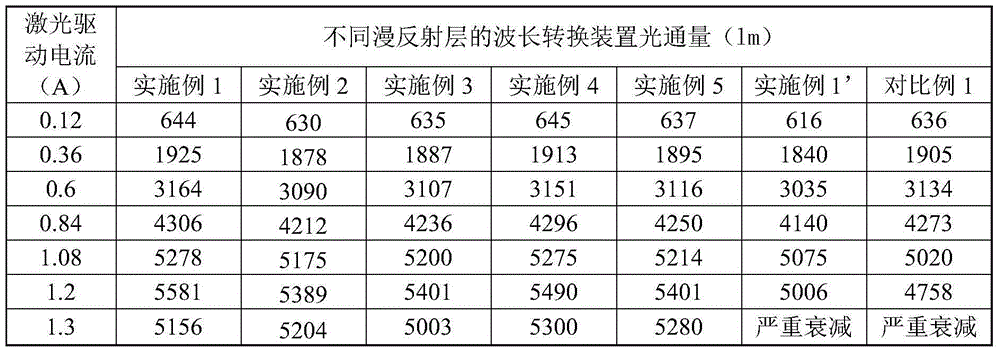

Embodiment 1

[0062] Raw materials: 0.1g of alumina (spherical particle size 0.2μm), 0.6g of titanium oxide (spherical particle size of 0.2μm), boron nitride (flat shape, length in the flat direction is 0.7μm, length in the thickness direction is 0.02μm ) 0.4g, glass powder 1g.

[0063] Preparation method: mix aluminum oxide, titanium dioxide, boron nitride, and glass powder with 1 g of organic carrier (organic carrier is terpineol, butyl carbitol acetate, ethyl cellulose) to form a mixed material, and mix The material is scraped on the surface of the aluminum nitride substrate, sintered at 800°C, and the steps of scraping and sintering are repeated to form a diffuse reflection layer with a thickness of 30 μm, and the measured reflectance of the diffuse reflection layer is 92.4%.

Embodiment 2

[0065]Raw materials: 0.08g of magnesium oxide (spherical particle size 0.3μm), 0.7g of zirconia (spherical particle size of 0.3μm), aluminum nitride (rod shape, length in the longitudinal direction is 1.0μm, length in the circumferential diameter direction is 0.02μm ) 0.3g, glass powder 1g.

[0066] Preparation method: Mix the above-mentioned magnesium oxide, zirconium oxide, aluminum nitride, and glass powder with 1 g of organic carrier (the organic carrier is an aqueous solution of PVA) to form a mixed material, and scrape the mixed material on the surface of the silicon nitride substrate above, sintered at 600°C, repeating the steps of scraping and sintering to form a diffuse reflection layer with a thickness of 30 μm, and the measured reflectance of the diffuse reflection layer is 90.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com