Waterborne polyurethane, preparing method and waterborne polyurethane adhesive

A technology of water-based polyurethane and degree of polymerization, applied in the field of water-based polyurethane, water-based polyurethane adhesives, and preparation, can solve the problems of high hard segment content and brittle polyurethane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention provides a kind of preparation method of waterborne polyurethane described in above-mentioned technical scheme, comprises the following steps:

[0042] Step 1: under the protection of inert gas, poly(carbonate-ether) glycol and diisocyanate are reacted to obtain the first intermediate;

[0043] Step 2: reacting dimethylolpropionic acid, a catalyst and the first intermediate obtained in step 1 to obtain a second intermediate;

[0044] Step 3: reacting the second intermediate obtained in step 2 with a novel glycol chain extender to obtain a third intermediate;

[0045] Step 4: reacting the third intermediate obtained in step 3 with triethylamine to obtain the fourth intermediate;

[0046] Step five: react the fourth intermediate obtained in step four with sodium disulfamate to obtain water-based polyurethane.

[0047] According to the present invention, under the protection of nitrogen or argon inert gas, poly(carbonate-ether) glycol and diisocyana...

Embodiment 1

[0068] Preparation of embodiment 1 propylene carbonate and diamine ring-opening dihydric alcohol:

[0069] Put 196g of propylene carbonate and 60g of ethylenediamine into a flask, add 490g of dichloromethane, heat and stir at 45°C for 26h, remove the dichloromethane under reduced pressure, wash the product with 150mL of ethylene glycol butyl ether and 200mL of ethanol, The product was vacuum-dried at 35°C for 72 hours to obtain ring-opened diols of propylene carbonate and ethylenediamine.

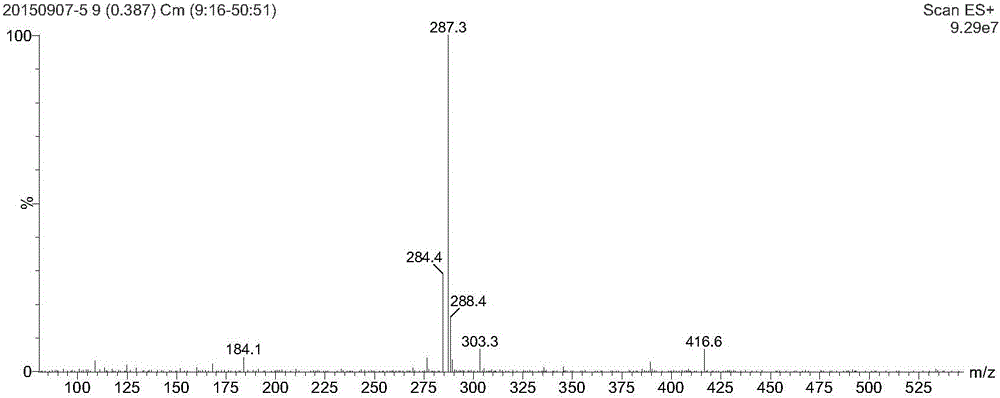

[0070] figure 1 For the electrospray mass spectrum of propylene carbonate and ethylenediamine ring-opening diol prepared in Example 1 of the present invention; according to the mass spectrum results, there is The strong peak, that is, the molecular weight of the product is 264, indicating that the product is a ring-opened dihydric alcohol of propylene carbonate and ethylenediamine.

Embodiment 2

[0071] Preparation of embodiment 2 propylene carbonate and diamine ring-opening dihydric alcohol:

[0072] Put 203g of propylene carbonate and 116.2g of 1,6-hexanediamine into the flask, add 480g of dichloromethane, heat and stir at 68°C for 15h, remove the dichloromethane under reduced pressure, and use 320mL of ethylene glycol butyl ether, The product was washed with 410 mL of ethanol, and the product was vacuum-dried at 55° C. for 24 hours to obtain the ring-opened diol of propylene carbonate and hexamethylenediamine.

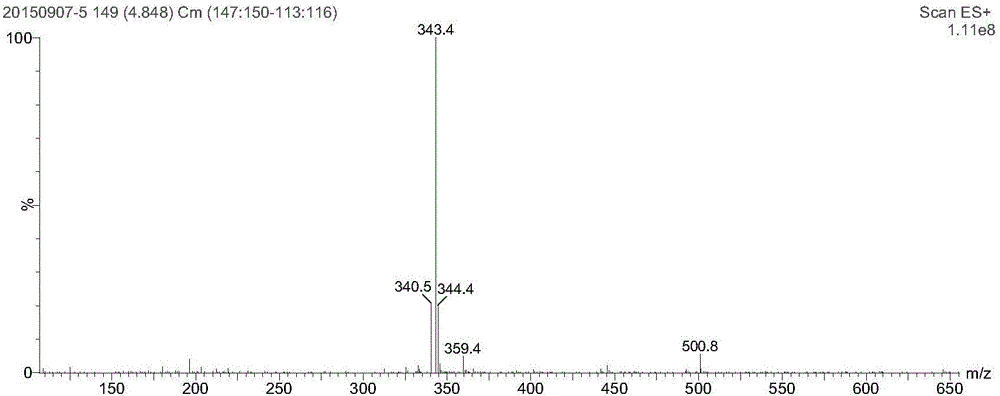

[0073] figure 2 For the electrospray mass spectrum of propylene carbonate and hexamethylenediamine ring-opening diol prepared in Example 2 of the present invention; according to the mass spectrum results, there are only 343.4 (product+Na, hexamethylenediamine molecular weight 116, propylene carbonate molecular weight 102) There is a peak, that is, the molecular weight of the product is 320, indicating that the product is a ring-opened diol of propylene car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com