A kind of water-based polyurethane, preparation method and water-based polyurethane adhesive

A technology of water-based polyurethane and degree of polymerization, applied in the field of preparation, water-based polyurethane adhesive, and water-based polyurethane, can solve the problems of polyurethane brittleness and high hard segment content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention provides a method for preparing an aqueous polyurethane described in the above technical solution, which includes the following steps:

[0042] Step 1: Under the protection of inert gas, react poly(carbonate-ether) glycol and diisocyanate to obtain the first intermediate;

[0043] Step 2: Reacting dimethylolpropionic acid, a catalyst, and the first intermediate obtained in Step 1, to obtain a second intermediate;

[0044] Step 3: Reacting the second intermediate obtained in Step 2 with a novel glycol chain extender to obtain a third intermediate;

[0045] Step 4: Reacting the third intermediate obtained in Step 3 with triethylamine to obtain the fourth intermediate;

[0046] Step five: reacting the fourth intermediate obtained in step four with sodium diaminosulfonate to obtain waterborne polyurethane.

[0047] According to the present invention, under the protection of nitrogen or argon inert gas, the poly(carbonate-ether) glycol and diisocyanate are reacted...

Embodiment 1

[0068] Example 1 Preparation of propylene carbonate and diamine ring-opening diol:

[0069] Put 196g of propylene carbonate and 60g of ethylenediamine into a flask, add 490g of dichloromethane, heat and stir at 45°C for 26h, remove the dichloromethane under reduced pressure, and wash the product with 150mL of ethylene glycol butyl ether and 200mL of ethanol. The product was vacuum dried at 35°C for 72h to obtain a ring-opening diol of propylene carbonate and ethylenediamine.

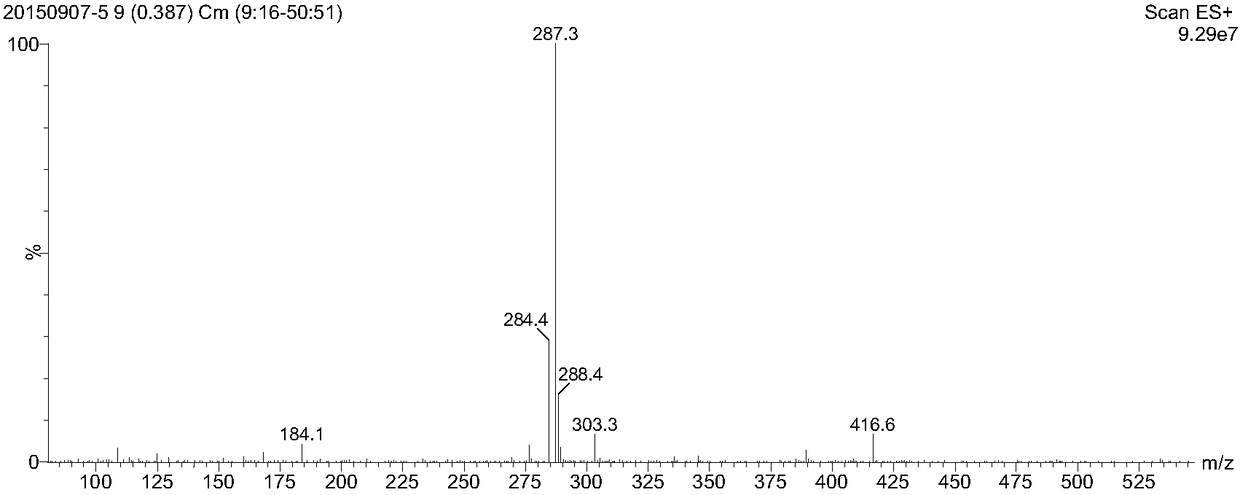

[0070] figure 1 This is the electrospray mass spectrometry of the propylene carbonate and ethylenediamine ring-opening diol prepared in Example 1 of the present invention; according to the mass spectrometry results, 287.3 (product + Na, ethylenediamine molecular weight 60, propylene carbonate molecular weight 102) nearby The strong peak, that is, the molecular weight of the product is 264, indicating that the product is a ring-opening diol of propylene carbonate and ethylenediamine.

Embodiment 2

[0071] Example 2 Preparation of propylene carbonate and diamine ring-opening diol:

[0072] Put 203g of propylene carbonate and 116.2g of 1,6-hexanediamine into the flask, add 480g of dichloromethane, heat and stir at 68°C for 15h, remove the dichloromethane under reduced pressure, and use 320mL of ethylene glycol butyl ether, The product was washed with 410 mL of ethanol, and the product was vacuum dried at 55° C. for 24 hours to obtain propylene carbonate and hexamethylene diamine ring-opening diol.

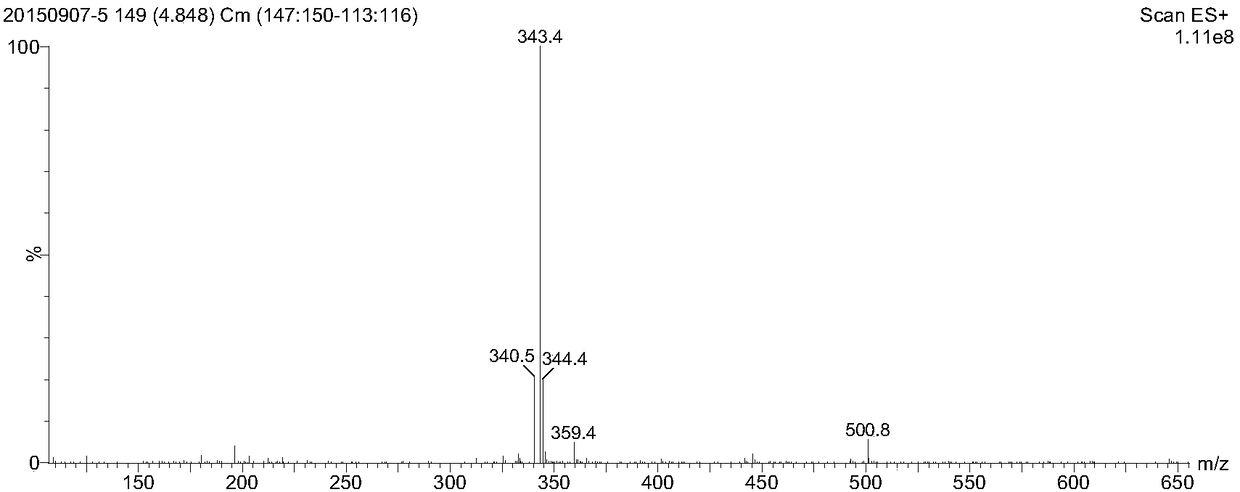

[0073] figure 2 This is the electrospray mass spectrometry of the propylene carbonate and hexamethylene diamine ring-opening diol prepared in Example 2 of the present invention; according to the mass spectrometry results, only 343.4 (product + Na, molecular weight of hexamethylene diamine 116, molecular weight of propylene carbonate 102) There is a peak, that is, the molecular weight of the product is 320, indicating that the product is a ring-opening diol of propylene carbonate an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com