Aminated starch-based nanocomposite material and preparation method thereof

A nanocomposite material, starch nanotechnology, applied in the field of aminated starch-based nanocomposite materials and its preparation, can solve the problems of affecting the reinforcement effect, difficulty in starch dispersion, weak interaction between starch and polymer matrix, etc., to achieve improved dispersion , excellent mechanical properties and environmental friendliness, the effect of improving the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Preparation of Aminated Starch Nanoparticles

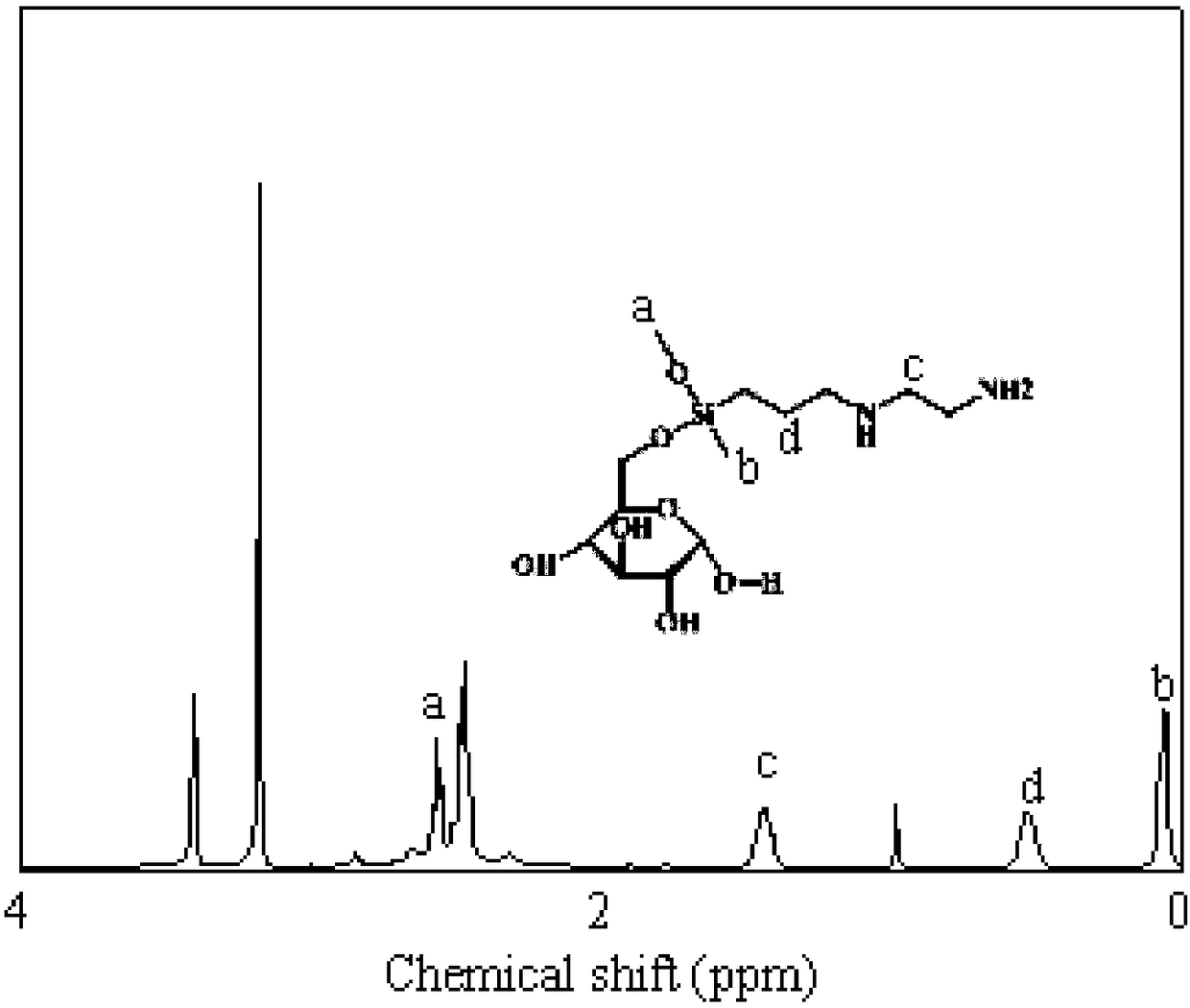

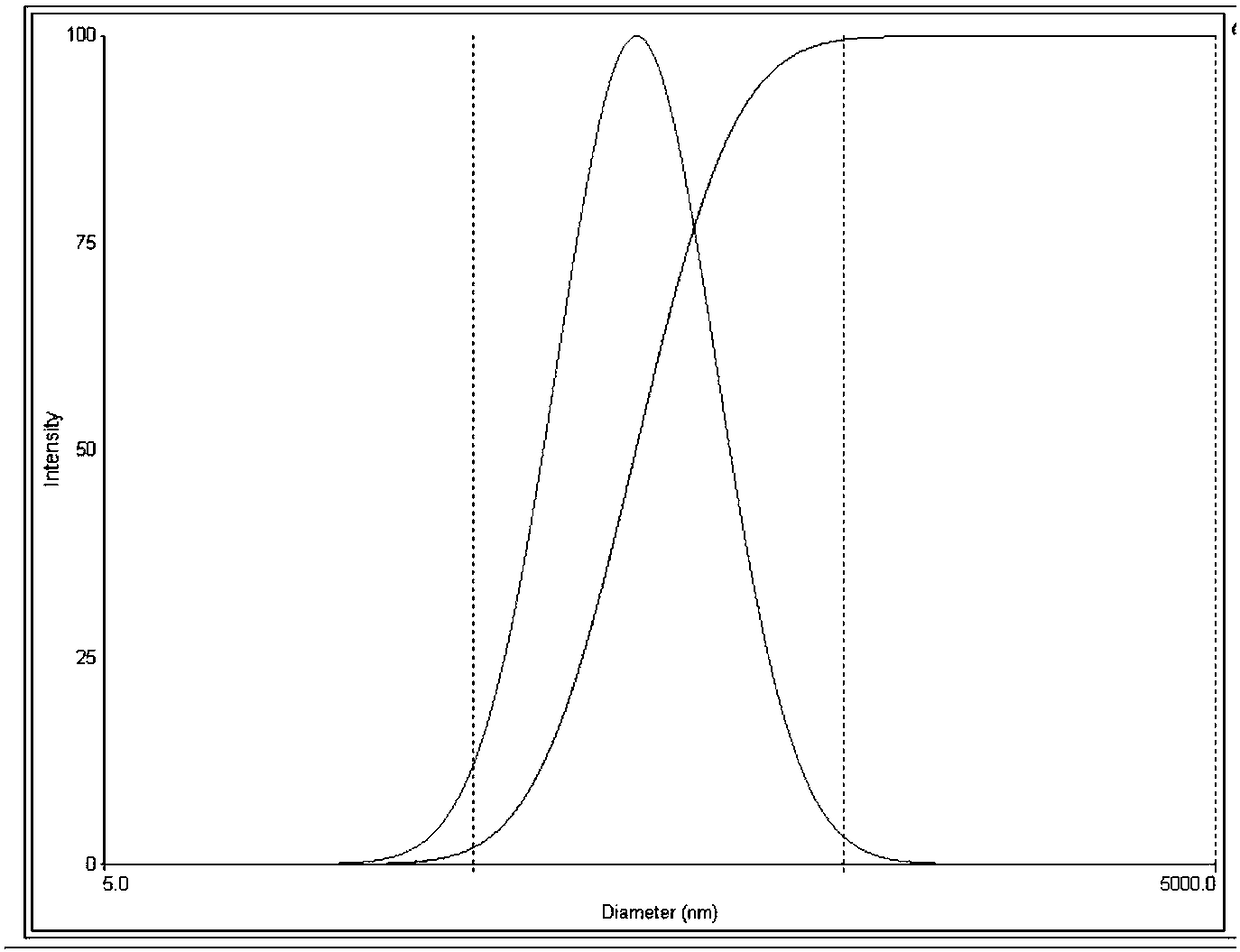

[0052] First, 900mL dimethyl sulfoxide, 100mL water and 10mL N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane (chemical structure: NH 2 CH 2 CH 2 NHCH 2 CH 2 CH 2 SiCH 3 (OCH 3 ) 2 ) mixed, stirred at room temperature at 500rpm for 15min and then warmed up to 90°C, 10g of natural tapioca starch was weighed and dispersed therein, stirred at 800rpm, heated in a water bath for 60min to form a clear and transparent starch solution, cooled to room temperature; 5L of ethanol with a mass concentration of 99.7% was gradually Add it dropwise into the above starch solution, stir continuously at a stirring rate of 750rpm to obtain an aminated nano-starch suspension; subject the suspension to ultrasonic treatment for 60 minutes, centrifuge it and wash it with ethanol for 3 times, and dry it at 90°C for 48 hours. Aminated nano starch particles are obtained.

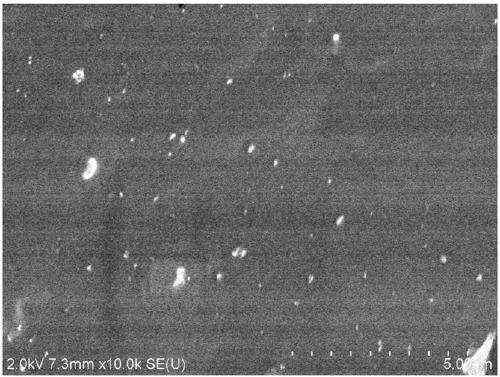

[0053] The morphology and chemical structure of aminated starch na...

Embodiment 2

[0058] Preparation of Aminated Starch Nanoparticles

[0059] Mix 900mL dimethylsulfoxide, 100mL water and 10mL 3-aminopropyltriethoxysilane (chemical structure: NH 2 CH 2 CH 2 CH 2 Si(OC 2 h 5 ) 3 ) and mix, stir at 500rpm at room temperature for 15min and then heat up to 95°C, weigh 10g of natural potato starch and disperse it, stir at 800rpm, heat in a water bath for 90min to form a clear and transparent starch solution, and cool to room temperature; dilute 6L with 1.25g of Span 80 and The ethanol solution of 3.75g Tween 80 (mass concentration is 99%) is dripped into above-mentioned starch solution dropwise, constantly stirs, and speed 750rpm obtains the nano-starch suspension of amination; The suspension is carried out sonication 60min, It was centrifuged, washed with ethanol three times, and dried at 90° C. for 48 hours to obtain aminated nano-starch particles.

[0060] The morphology and chemical structure of aminated starch nanoparticles were characterized by dyna...

Embodiment 3

[0062] Mix 800mL dimethyl sulfoxide, 120mL water and 10g glycine (chemical structure: NH 2 CH 2 COOH) mixed, stirred at 500rpm at room temperature for 15min and then heated to 95°C, weighed 10g of tapioca starch and 0.05g of stannous octoate and dispersed them, stirred at 800rpm, heated in a water bath for 180min to form a clear and transparent starch solution, cooled to room temperature; 6L of ethanol solution (mass concentration is 99%) drip into above-mentioned starch solution dropwise, constantly stir, speed 750rpm, obtain the nano-starch suspension of amination; The suspension is carried out sonication 60min, it is centrifuged and washed with ethanol for 3 Once, dry at 90°C for 48 hours to obtain aminated nano-starch particles.

[0063] The morphology and chemical structure of aminated starch nanoparticles were characterized by dynamic light scattering and degree of substitution formula, respectively. The results are as follows: the particle size is 120±10nm, the polydi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com