Thermal decomposition material, clad material for power system and power system

A technology of power supply system and coating material, applied in the field of energy storage devices, can solve problems such as unreasonable design of power supply system, fire, and inadequate design of collision protection of power supply system, and achieve the effect of avoiding location limitations and monitoring hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The pyrolysis material of the present embodiment is made up of the component of following percentage by weight: 10% inorganic foaming agent sodium bicarbonate (NaHCO 3 ), 60% of the organic blowing agent azodicarbonamide (AC), 20% of the organic blowing agent diphenylsulfonyl hydrazide oxide (OT), and 10% of the additive zinc oxide (ZnO). The pyrolysis material in this example can decompose and release decomposition gas at 100°C±5°C, and the main component of the decomposition gas released by the pyrolysis material within this temperature range is CO 2 , N 2 Wait for gas.

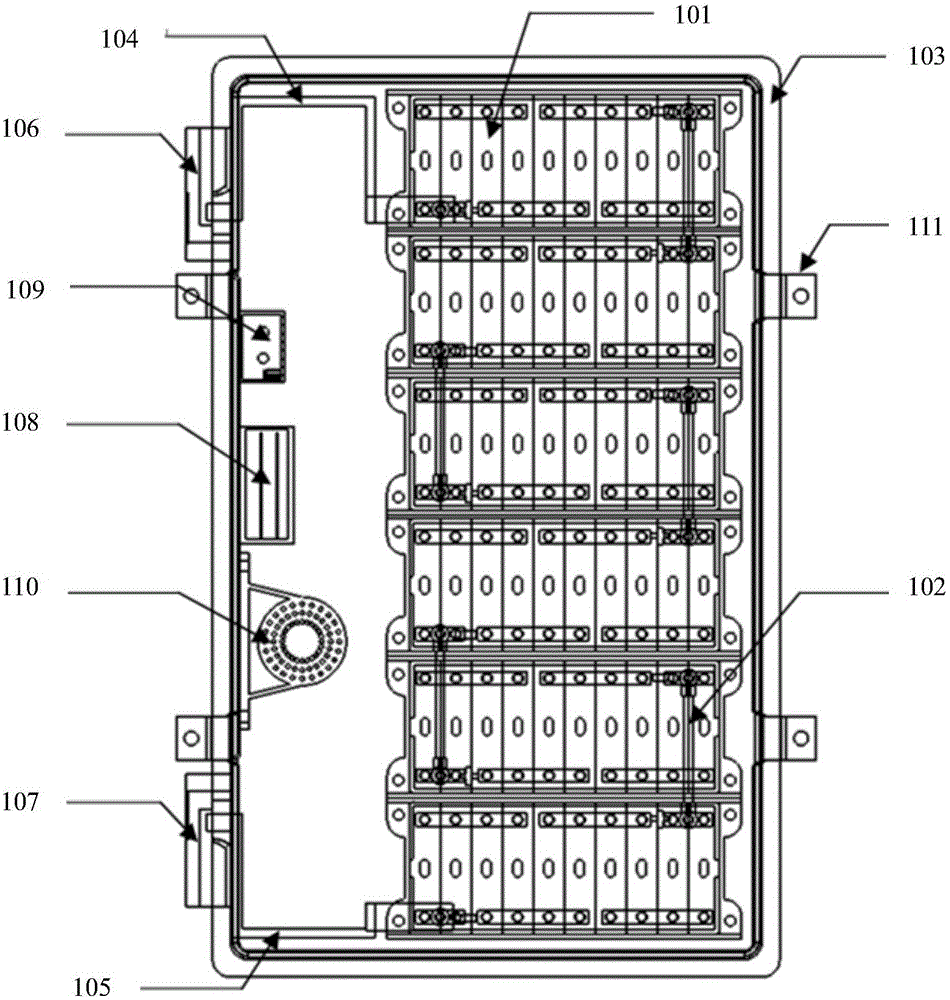

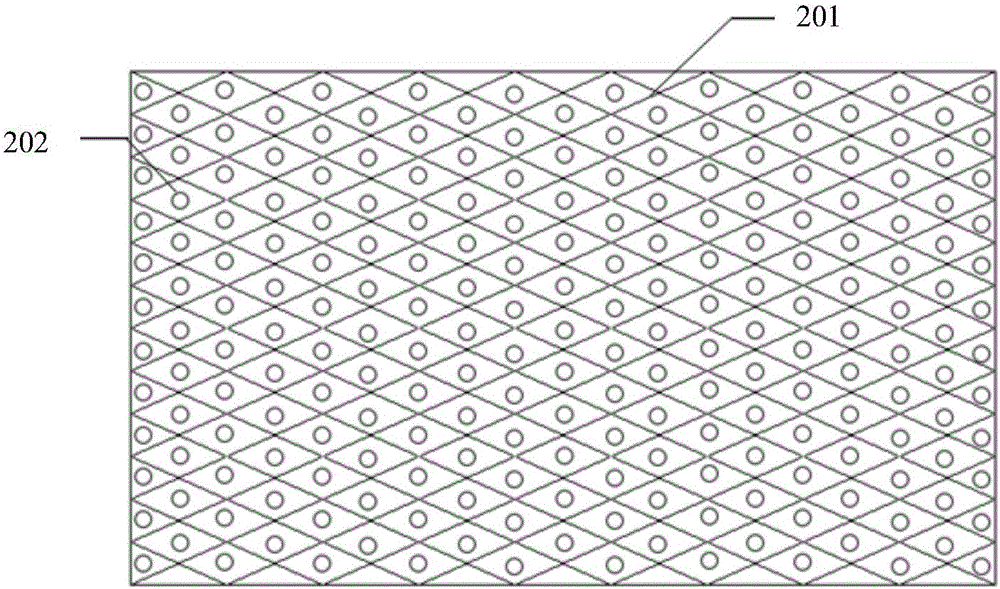

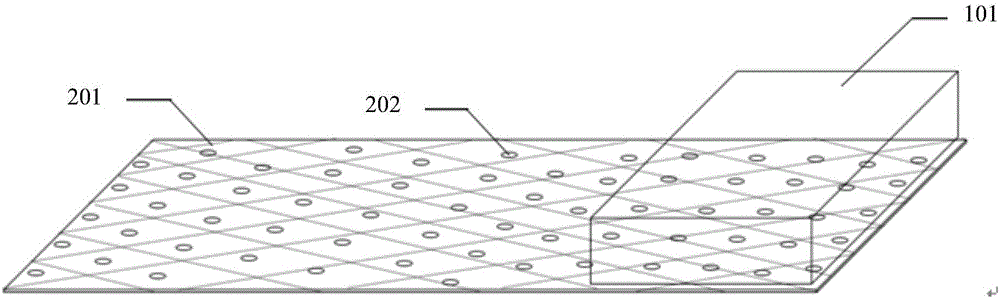

[0055] The cladding material for the power supply system of this embodiment includes a base material 201 and the above-mentioned thermal decomposition material 202 attached to the base material (such as figure 2 shown), the base material is PP. The method of attachment is as follows: use a porous substrate with a large number of pore structures on the surface and inside of the substrate, mix the ...

Embodiment 2

[0057] The pyrolysis material of the present embodiment is made up of the component of following percentage by weight: 80% inorganic blowing agent sodium bicarbonate (NaHCO 3 ), 10% of the organic blowing agent azodicarbonamide (AC), 5% of the organic blowing agent diphenylsulfonyl hydrazide oxide (OT), and 5% of the auxiliary agent zinc oxide (ZnO). The pyrolysis material in this example can decompose and release decomposition gas at 130°C±5°C, and the main component of the decomposition gas released by the pyrolysis material within this temperature range is CO 2 , N 2 Wait for gas.

[0058] The covering material for a power supply system in this embodiment includes a base material and the above-mentioned pyrolysis material attached to the base material, and the base material is PP. The method of attachment is as follows: use a porous substrate with a large number of pore structures on the surface and inside of the substrate, mix the above-mentioned pyrolysis materials even...

Embodiment 3

[0060] The pyrolysis material of the present embodiment is made up of the component of following percentage by weight: 5% inorganic foaming agent sodium bicarbonate (NaHCO 3 ), 10% of the organic foaming agent azodicarbonamide (AC), 55% of the organic foaming agent diphenylsulfonyl hydrazide oxide (OT), and 30% of the additive zinc oxide (ZnO). The pyrolysis material in this embodiment can decompose and release decomposition gas at 140°C±5°C, and the main component of the decomposition gas released by the pyrolysis material within this temperature range is CO 2 , N 2 Wait for gas.

[0061] The covering material for a power supply system in this embodiment includes a base material and the above-mentioned pyrolysis material attached to the base material, and the base material is PP. The method of attachment is as follows: use a porous substrate with a large number of pore structures on the surface and inside of the substrate, mix the above-mentioned pyrolysis materials evenly,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com