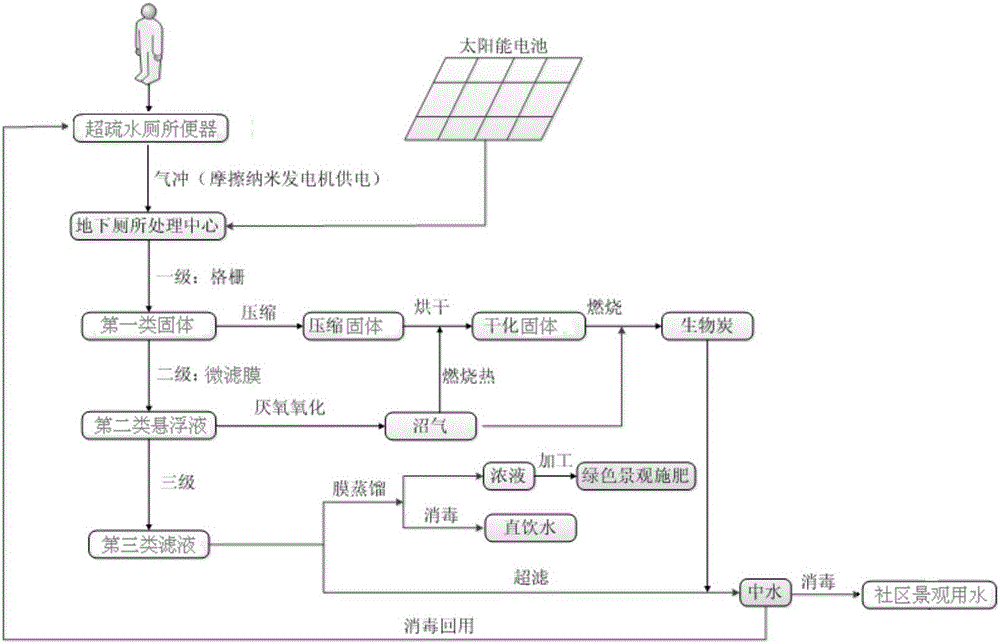

Toilet wastewater treatment process

A technology for wastewater treatment and toilet, applied in the field of toilet wastewater treatment technology, can solve the problems of inaccessibility, attract mosquitoes, low cost, etc., and achieve the effects of preventing urine scale formation, improving adsorption performance, and increasing adsorption area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The toilet wastewater first passes through the toilet bowl coated with a superhydrophobic coating film made of PE nanometer superhydrophobic interface material, and then 8 friction nanoelectric power generation using the polymer polydimethylsiloxane film coated with silver electrodes as the contact surface The motor drives the air flushing unit to flush the toilet wastewater into the drainage pipe, and the toilet wastewater is classified and collected and treated in the underground toilet treatment center.

[0031] The first-stage treatment is drying treatment, using 4-purpose grids to separate toilet paper and large particles to obtain the first type of solids, and then burn the collected first-type solids through a solar-powered compression water remover and biogas The heat produced is dried, and the volume of the solid after drying is compressed by 70%. Finally, the obtained solid is fired into biochar in a muffle furnace powered by solar energy in a biogas atmosphere...

Embodiment 2

[0037] The toilet wastewater first passes through the toilet pan coated with a super-hydrophobic coating film made of PTE nano-super-hydrophobic interface material, and uses five polymer polydimethylsiloxane films coated with silver electrodes as the contact surface to drive the frictional nano-generator. The air flushing unit flushes the toilet wastewater into the drainage pipe, and the toilet wastewater is classified and collected and treated in the third stage in the underground toilet treatment center.

[0038] The first-stage treatment is drying treatment, using a 50-mesh grid to separate toilet paper and large particles to obtain the first type of solids, and then burn the collected first-type solids through a solar-powered compression water remover and biogas The generated heat is dried, and the volume of the solid after drying is compressed by 80%. Finally, the obtained solid is burned into biochar in a muffle furnace powered by solar energy in a biogas atmosphere at 30...

Embodiment 3

[0044] The toilet wastewater first passes through the toilet bowl coated with a superhydrophobic coating film made of EVA nanometer superhydrophobic interface material, and uses three polymer polydimethylsiloxane films coated with gold electrodes as the contact surface to drive the frictional nanogenerator. The air flushing unit flushes the toilet wastewater into the drainage pipe, and the toilet wastewater is classified and collected and treated in the third stage in the underground toilet treatment center.

[0045] The first-stage treatment is drying treatment, using 150-mesh grids to separate toilet paper and large particles, which are called the first-class solids, and then the collected first-class solids are passed through a solar-powered compression dehydrator and biogas The heat produced by combustion is dried, and the volume of the solid after drying is compressed by 90%. Finally, the obtained solid is burned into biochar in a muffle furnace powered by solar energy in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com