Structure of ultrathin membrane electrode for SPE water electrolysis and preparation and application of structure

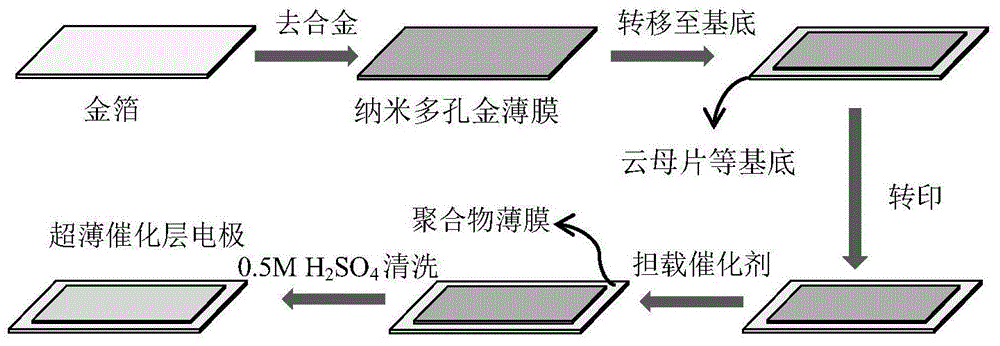

An ultra-thin film and water electrolysis technology, applied in battery electrodes, solid electrolyte fuel cells, electrodes, etc., can solve the problems of hydrazine toxicity, nanoporous gold film fragility, increase the difficulty of nanoporous gold surface modification, etc., and achieve high utilization rate High, improved dispersion and stability, the effect of low amount of precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

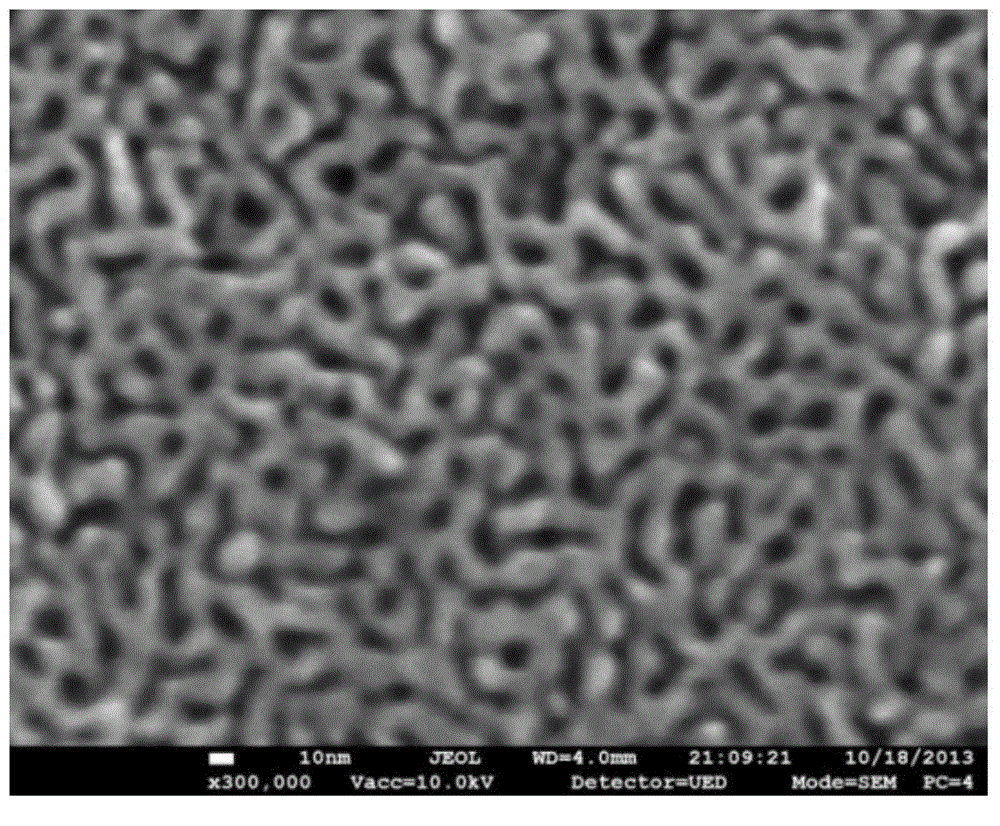

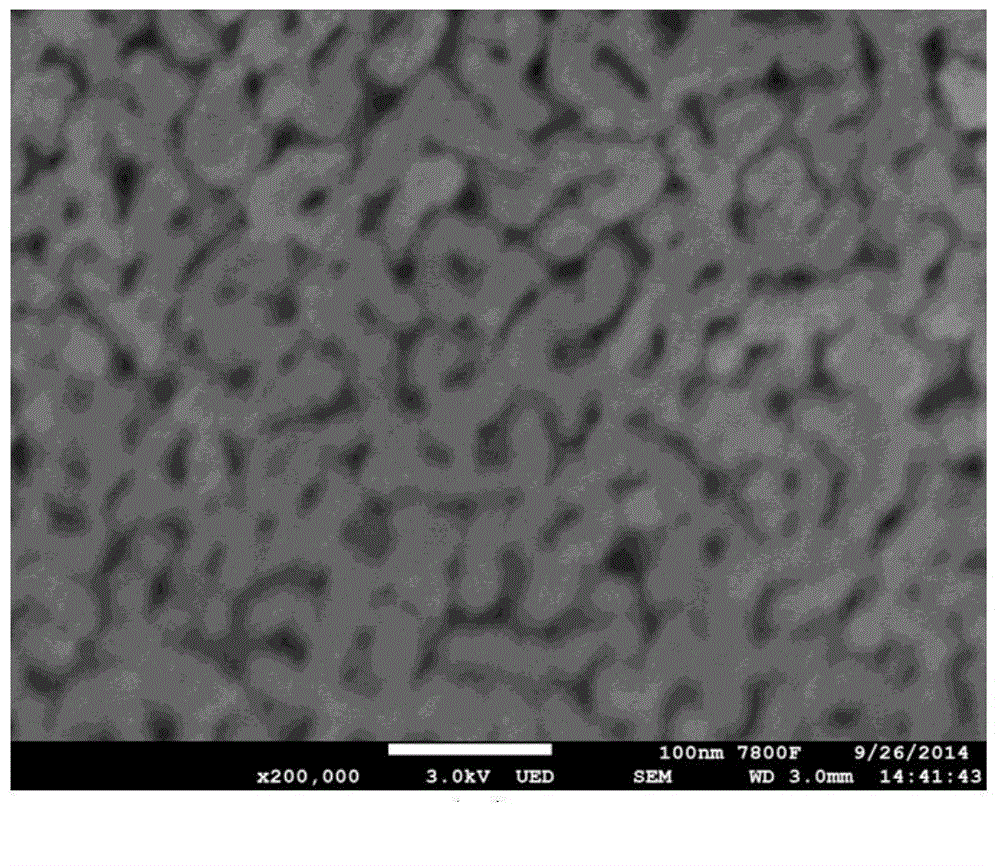

[0035] With 12K gold leaf (Au 50 Ag 50wt.%) is the raw material, the gold foil is cut into a suitable size (2.1cm*2.1cm), the gold foil is spread on the surface of deionized water, and transferred to dilute nitric acid (the volume ratio of nitric acid and deionized water is 2:1), the reaction time was controlled to be 30min, and the prepared nanoporous gold was labeled as NPG(30). The nanoporous gold film (NPG, nanoporous goldfilm) obtained after dealloying is transferred to deionized water, and the nanoporous gold film is spread on the surface of deionized water at this time; replace deionization 3-4 times, remove the nanoporous gold film. nitric acid; the nanoporous gold film is transferred to a mica sheet (size 2.5cm × 4.0cm), and dried at room temperature; the Nafion211 film is covered on the side with the nanoporous gold film, and hot-pressed at 150°C and 5MPa 3min; carefully remove the mica sheet, and wash the obtained Nafion membrane with deionized water. The pore di...

Embodiment 2

[0039] Refer to Example 1 for the preparation and transfer process of the nanoporous gold film.

[0040] Pt and Ir were co-electrodeposited on the nanoporous gold film by constant potential electrodeposition. The specific operation method: construct a three-electrode system, connect the Nafion211 film with the nanoporous gold film and the wire as the working electrode, use the high-purity graphite plate as the counter electrode, and use the saturated calomel electrode as the reference electrode; before electroplating , place the working electrode in a fully deoxygenated 0.5MH 2 SO 4 Cyclic voltammetry (CV) was used in the solution to remove pollutants on the surface. The potential range of cyclic voltammetry was (0.0V, 1.7V) (vs.RHE), and the scan rate was 100mV / s for 30min; then the working electrode Switch to the electroplating solution, the composition of the electroplating solution: 0.4mMH 2 IrCl 6 , 0.5mMH 2 PtCl 6 , 0.5MH 2 SO 4 As a supporting electrolyte; the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com