Formation method of semiconductor structure

A semiconductor and conductor layer technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of semiconductor structure production yield and chip output to be improved, so as to improve production yield and chip output The effect of reducing the amount, reducing the difficulty of the process, and preventing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

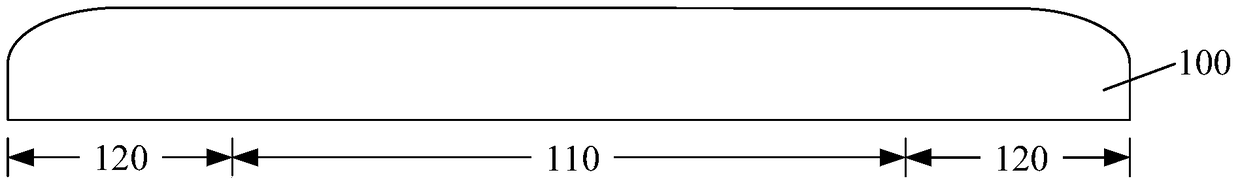

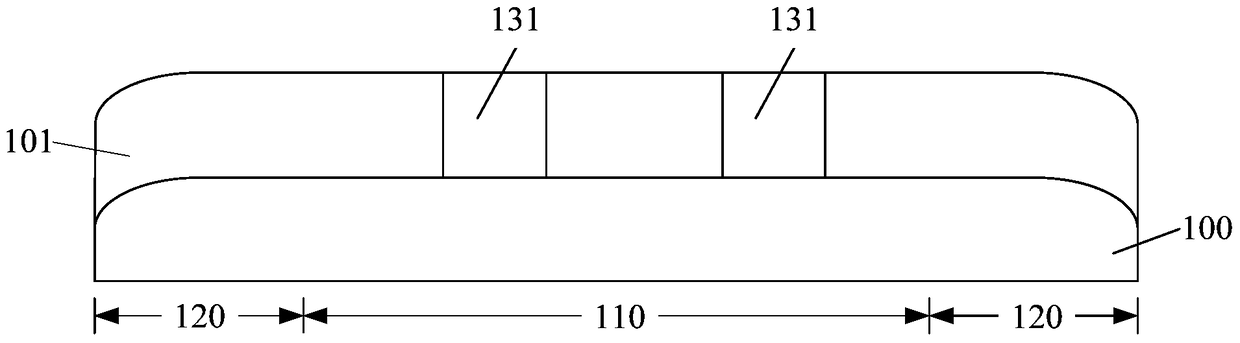

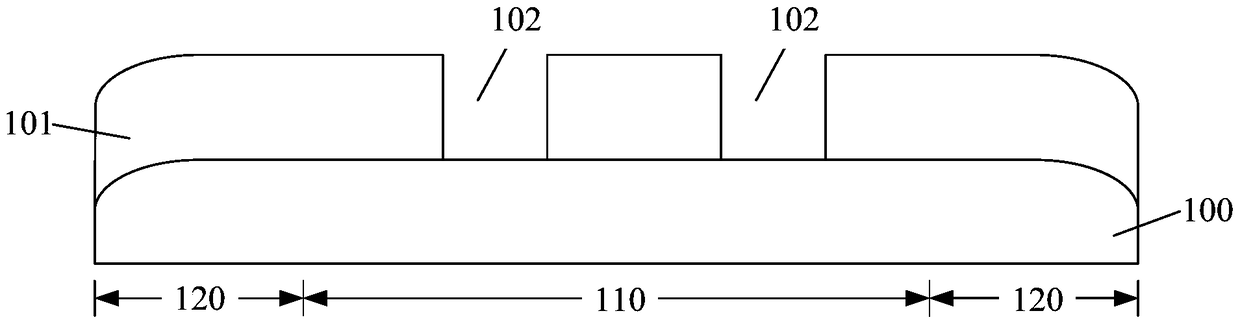

[0035] It can be seen from the background art that the substrate in the prior art device production process is easily damaged or polluted, resulting in low production yield of the semiconductor structure and low chip output.

[0036] It has been found through research that in semiconductor manufacturing, multiple processes need to be involved, and the dry etching process is usually a common step in the manufacturing process. The dry etching process uses the reactive gas to obtain energy, and then etches the etching object through a physical or chemical reaction. However, during etching, or other processes, by-products are usually formed near the edge of the substrate, such as polymers containing elements such as carbon, oxygen, nitrogen, and fluorine, and low-quality films due to edge effects layers etc.

[0037] In the subsequent process, the adhesion between the by-product and the substrate will eventually weaken, causing the by-product to spall or peel off during the trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com