Preparation method of flexible carbon nanotube-polyaniline thermoelectric device

A technology of carbon nanotubes and thermoelectric devices, which is applied in the manufacture/processing of thermoelectric devices, and materials for the lead-out wires of thermoelectric devices. It can solve problems such as limitations, poor folding performance, and insufficient flexibility, and achieve light weight. Simple, flexible and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Add 15mg of carbon nanotubes and 45mg of sodium dodecylbenzenesulfonate into 60mL of 1mol / L HCl solution, sonicate for 30min, treat with a cell pulverizer for 120min, add 15mg of aniline, sonicate for 30min, and proceed under ice bath Magnetic stirring;

[0032] (2) Add 45 mg of ammonium persulfate to 5 mL of 1mol / L HCl solution, and stir evenly; add the ammonium persulfate solution into the syringe and inject it into the stirring (1) within 30 minutes, and stir for 12 hours in an ice bath to obtain Carbon nanotube-polyaniline composite solution;

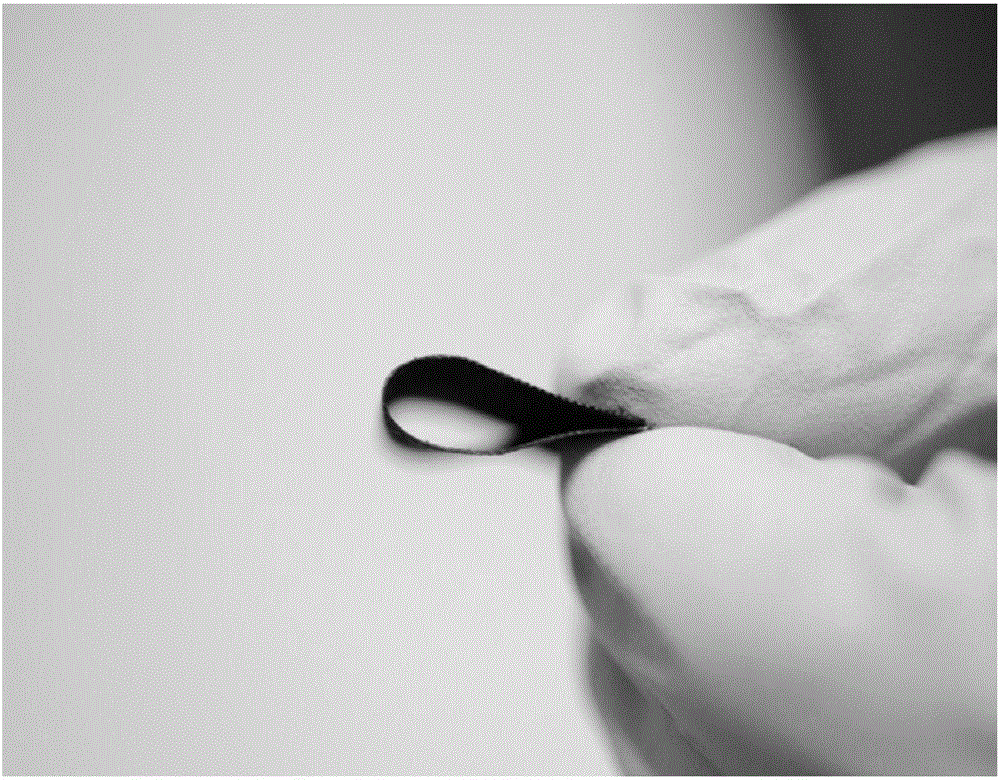

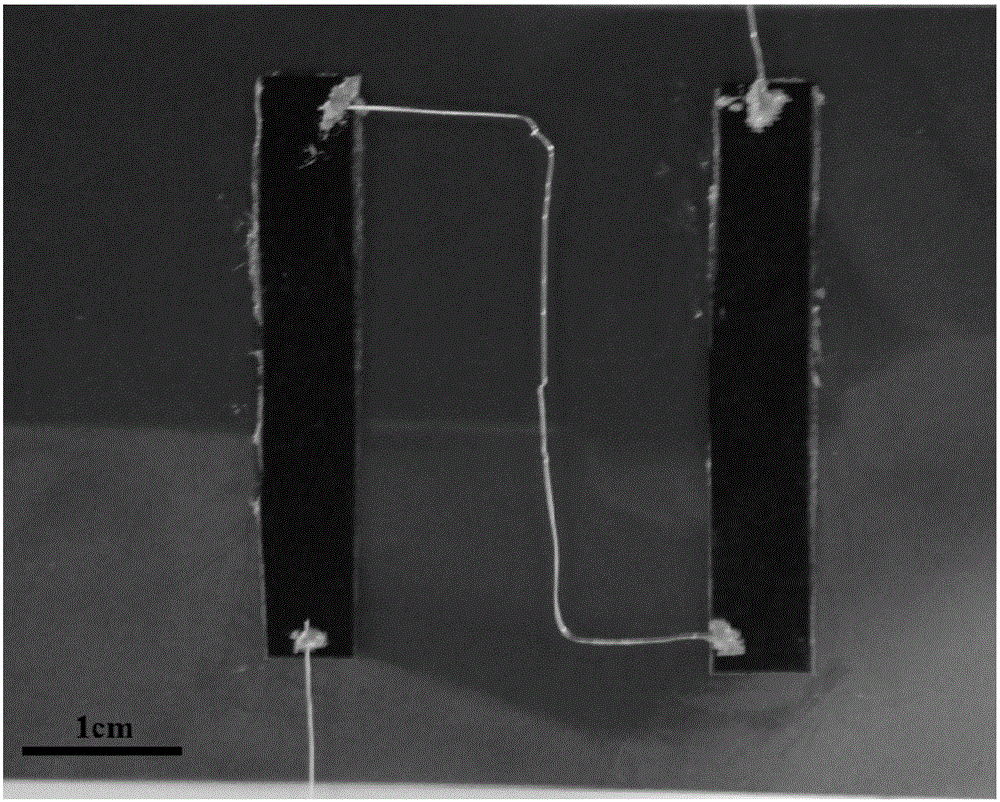

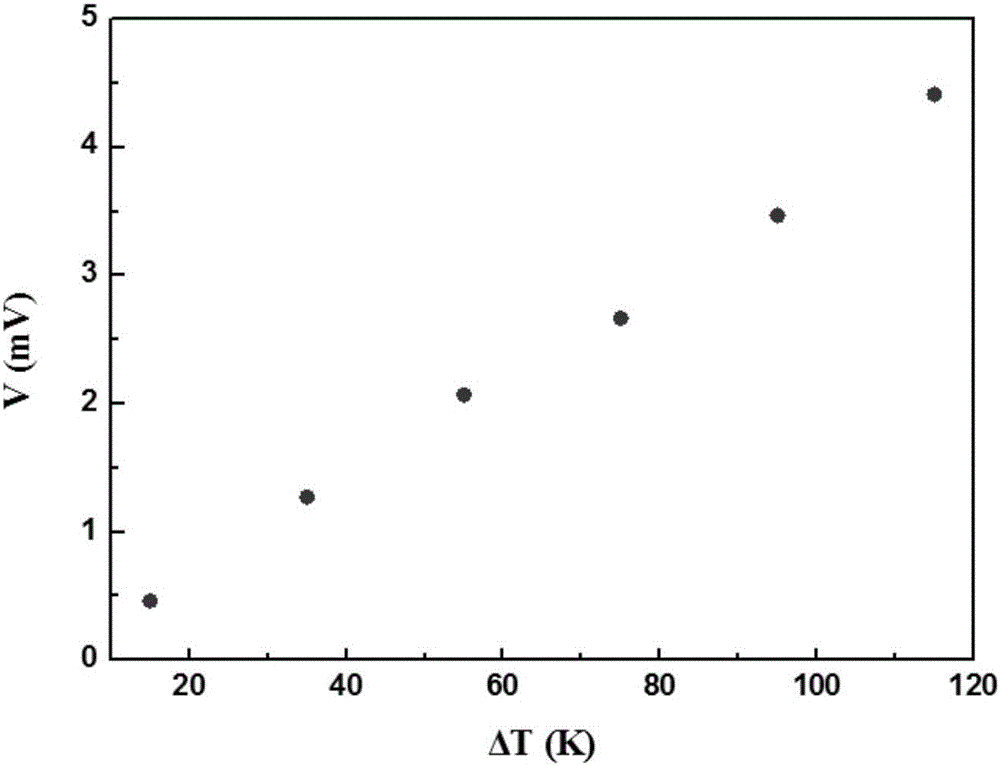

[0033] (3) Put the polyester with a mass fraction of 5% into a sodium hydroxide solution and heat it in an oil bath at 75°C for 10 minutes, then put the polyester cloth piece into a 75°C aqueous solution and stir it magnetically for 10 minutes, take out the polyester and dry it and add it to the solution obtained in (2) solution, and sonicated for 2 hours, and then dried under vacuum at 60°C for 6 hours. Repeat the abov...

Embodiment 2

[0037] (1) Add 15mg of carbon nanotubes and 45mg of sodium dodecylbenzenesulfonate into 60mL of 1mol / L HCl solution, sonicate for 30min, treat with a cell pulverizer for 120min, add 30mg of aniline, sonicate for 30min, and proceed under ice bath Magnetic stirring;

[0038] (2) Add 90 mg of ammonium persulfate to 10 mL of 1mol / L HCl solution, and stir evenly; add the ammonium persulfate solution into the syringe and inject it into the stirring (1) within 40 minutes, and stir for 12 hours under an ice bath to obtain Carbon nanotube-polyaniline composite solution;

[0039] (3) Put the polyester with a mass fraction of 5% into a sodium hydroxide solution and heat it in an oil bath at 75°C for 10 minutes, then put the polyester cloth piece into a 75°C aqueous solution and stir it magnetically for 10 minutes, take out the polyester and dry it and add it to the solution obtained in (2) solution, and sonicated for 2 hours, and then dried under vacuum at 60°C for 6 hours. Repeat the ...

Embodiment 3

[0042] (1) Add 15mg of carbon nanotubes and 45mg of sodium dodecylbenzenesulfonate into 60mL of 1mol / L HCl solution, sonicate for 30min, treat with a cell pulverizer for 120min, add 5mg of aniline, sonicate for 30min, and proceed under ice bath Magnetic stirring;

[0043] (2) Add 15 mg of ammonium persulfate to 3 mL of 1mol / L HCl solution, and stir evenly; add the ammonium persulfate solution into the syringe and inject it into the stirring (1) within 20 minutes, and stir for 12 hours in an ice bath to obtain Carbon nanotube-polyaniline composite solution;

[0044](3) Put the polyester with a mass fraction of 5% into a sodium hydroxide solution and heat it in an oil bath at 75°C for 10 minutes, then put the polyester cloth piece into a 75°C aqueous solution and stir it magnetically for 10 minutes, take out the polyester and dry it and add it to the solution obtained in (2) solution, and sonicated for 2 hours, and then dried under vacuum at 60°C for 6 hours. Repeat the above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com