Negative pole piece for lithium-ion battery and preparation method of negative pole piece

A technology of lithium-ion batteries and negative pole pieces, which is applied in the direction of electrode manufacturing, battery electrodes, batteries, etc., can solve the problems of effective capacity reduction and achieve the effects of increasing capacity, avoiding bulging, and avoiding consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A lithium-ion battery negative electrode sheet, comprising a copper foil with a thickness of 15um as a current collector and an active material coating coated on the surface of the current collector, and the surface of the active material coating is coated with an SEI with a thickness of 10nm film, the SEI film contains lithium salt material Li 2 CO 3 . Wherein, the density of the active material coating is 320g / m 2 ; Its raw materials include mass fraction 93% natural graphite, 3% conductive carbon black (SP), 1% conductive graphite (KS6), 3% CMC.

[0036] The present embodiment also provides a method for preparing the negative pole piece of the above-mentioned lithium ion battery, comprising the following steps:

[0037] 1) Take the raw materials for preparing the active material coating according to the following mass ratio: 93% natural graphite, 3% conductive carbon black (SP), 1% conductive graphite (KS6), 3% CMC; first put each raw material into Dry in a vacuu...

Embodiment 2

[0042] A lithium-ion battery negative electrode sheet, comprising a copper foil with a thickness of 15um as a current collector and an active material coating coated on the surface of the current collector, and the surface of the active material coating is coated with an SEI with a thickness of 20nm film, the SEI film contains a lithium salt substance (Li 2 CO 3 (50%wt)+ROCO 2 Li (50%wt)). Wherein, the density of the active material coating is 320g / m 2 ; Its raw materials include mass fraction 94% natural graphite, 2% conductive carbon black (SP), 1% conductive graphite (KS6), 3% CMC.

[0043] The present embodiment also provides a method for preparing the negative pole piece of the above-mentioned lithium ion battery, comprising the following steps:

[0044] 1) Take the raw materials for preparing the active material coating according to the following mass ratio: 94% natural graphite, 2% conductive carbon black (SP), 1% conductive graphite (KS6), 3% CMC; first put each raw ...

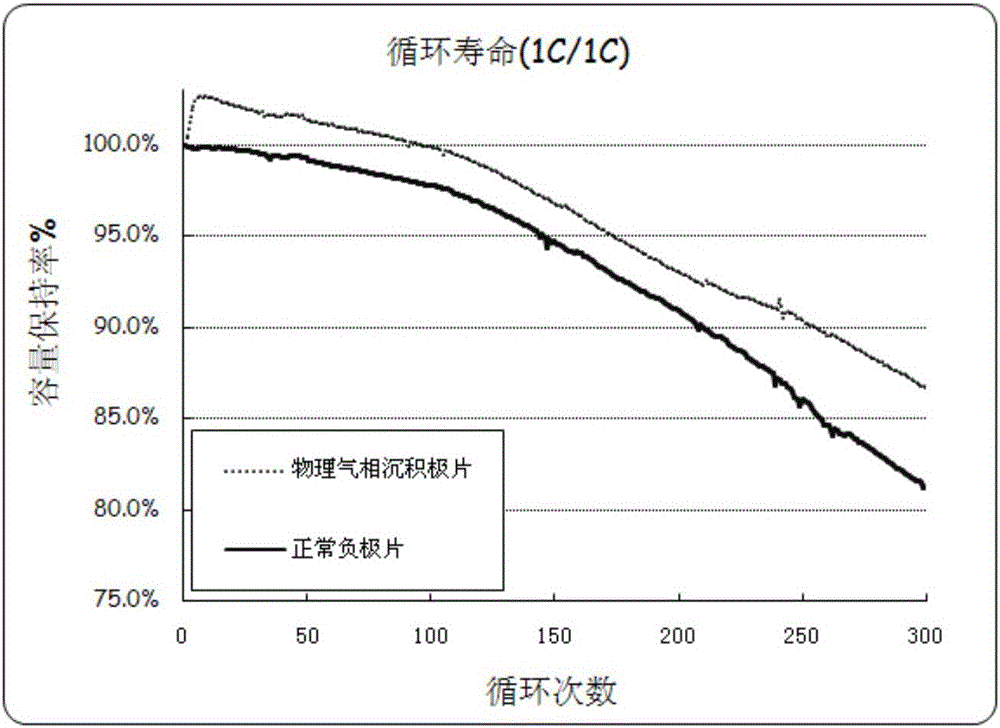

Embodiment 3

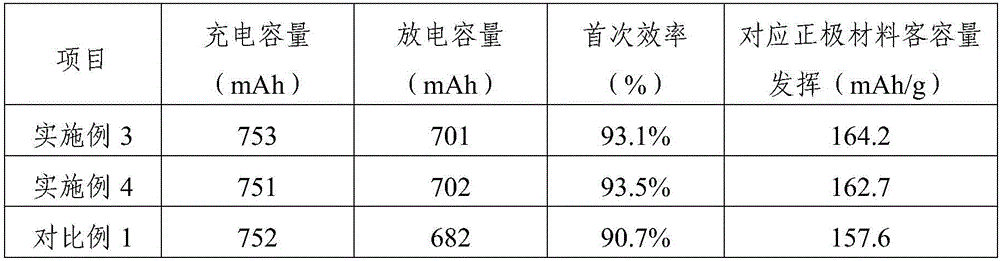

[0049] A kind of lithium-ion battery, the cathode ternary material (622 material), the lithium-ion battery negative pole piece that embodiment 1 makes, electrolytic solution, diaphragm etc. are made sheet-winding-welding-injection according to conventional lithium-ion battery technology -The sealing is made into 053048 aluminum shell battery. 0.1C charge and discharge test (3.0-4.3V) directly after sealing. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com