Preparation method for spirogyra-based biomass carbon material/nanometer sulfur composite material

A technology of biomass carbon and composite materials, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of poor electronic conductivity and ion conductivity of lithium sulfide, low utilization rate of positive active materials, Short cycle life and other issues, to achieve strong reproduction and adaptability, realize waste reuse, and good uniformity and continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Clean the spongy repeatedly to remove impurities, put it into a beaker and add deionized water to submerge the spongy, then ultrasonically clean for 30 minutes, then replace the cleaning solvent with ethanol and ultrasonically clean for 30 minutes, repeat the above cleaning process Three times (that is, water and ethanol are ultrasonically cleaned in turn, that is, water is washed once, ethanol is washed once; water is washed once, ethanol is washed once; water is washed once, ethanol is washed once. The following examples are the same) until the solution is clarified;

[0029] (2) Place the spongy cleaned in step 1 in a vacuum drying oven and dry at 60°C for 6 hours;

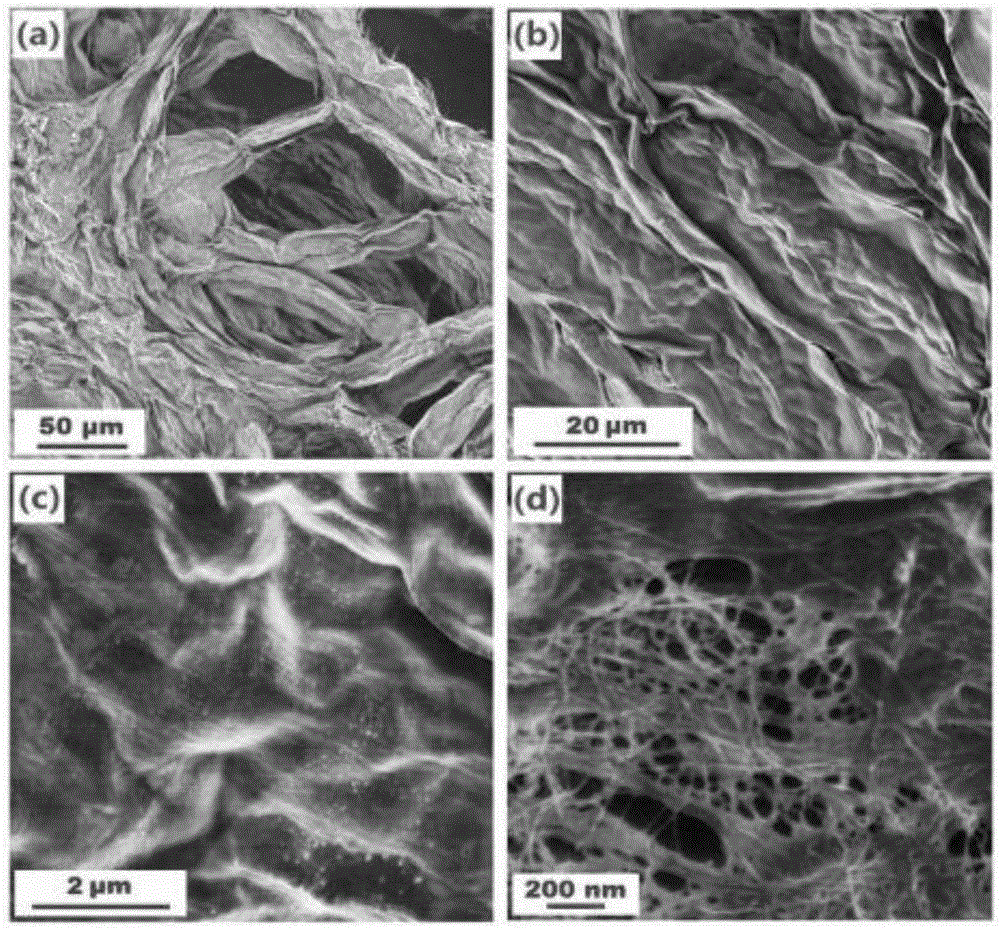

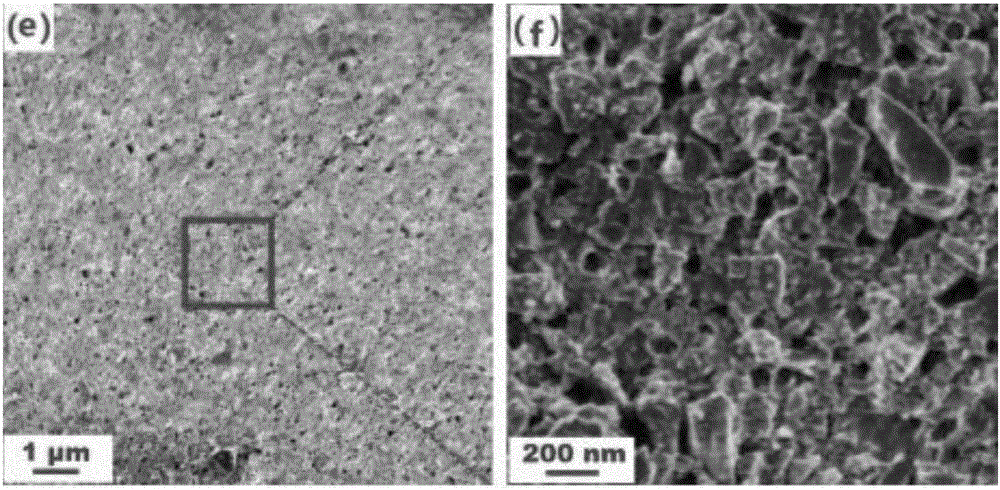

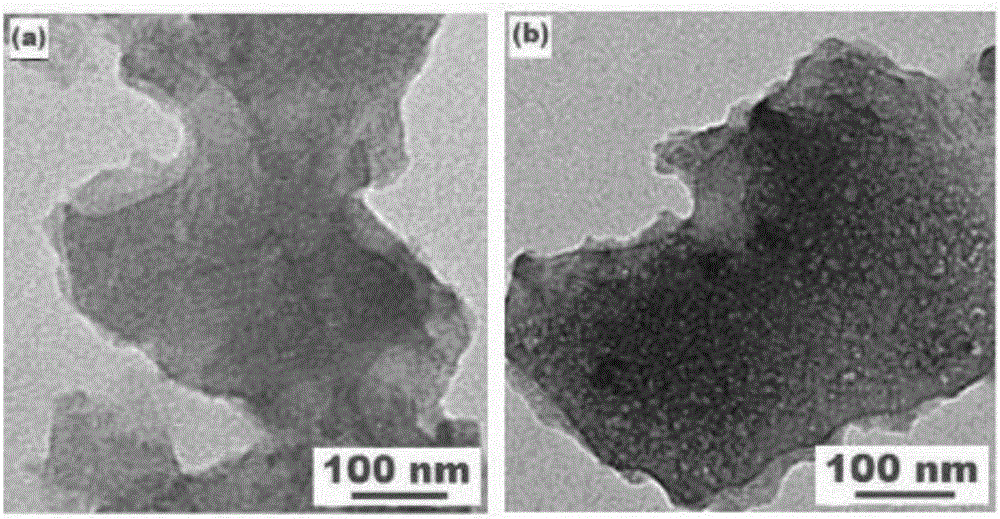

[0030] (3) Heat the spirogyra dried in step 2 through a vacuum tube furnace under the protection of an argon atmosphere, raise the temperature to 700°C at a rate of 5°C / min, keep it warm for 2 hours, and then cool it to room temperature with the furnace to obtain Spirogyne-based biomass carbon materi...

Embodiment 2

[0043] The preparation method of the spirogyra-based biomass carbon / nano-sulfur composite material applied to lithium-sulfur batteries has the same steps as in Example 1, except that the tube furnace in step (3) is heated to 500°C.

[0044] (1) Clean the spongy repeatedly to remove impurities, put it into a beaker and add deionized water to submerge the spongy, then ultrasonically clean for 30 minutes, then replace the cleaning solvent with ethanol and ultrasonically clean for 30 minutes, repeat the above cleaning process Three times until the solution is clear;

[0045] (2) Place the spongy cleaned in step 1 in a vacuum drying oven and dry at 60°C for 6 hours;

[0046] (3) Heat the spirogyra dried in step 2 through a vacuum tube furnace under the protection of an argon atmosphere, raise the temperature to 500°C at a rate of 5°C / min, keep it warm for 2 hours, and then cool it to room temperature with the furnace to obtain Spirogyra-based biomass carbon materials;

[0047] (4...

Embodiment 3

[0054] The preparation method of the spirogyra-based biomass carbon / nano-sulfur composite material applied to lithium-sulfur batteries, the steps are the same as those in Example 1, except that the tube furnace in step (3) is heated to 900°C.

[0055] (1) Clean the spongy repeatedly to remove impurities, put it into a beaker and add deionized water to submerge the spongy, then ultrasonically clean for 30 minutes, then replace the cleaning solvent with ethanol and ultrasonically clean for 30 minutes, repeat the above cleaning process Three times until the solution is clear;

[0056] (2) Place the spongy cleaned in step 1 in a vacuum drying oven and dry at 60°C for 6 hours;

[0057] (3) Heat the spirogyra dried in step 2 through a vacuum tube furnace under the protection of an argon atmosphere, raise the temperature to 900°C at a rate of 5°C / min, keep it warm for 2 hours, and then cool it to room temperature with the furnace to obtain Spirogyra-based biomass carbon materials; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com