Composite reverse osmosis membrane with high salt removing rate and controllable flux and method for preparing composite reverse osmosis membrane

A reverse osmosis membrane, composite technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of difficult membrane desalination and flux control, low water production, and high working pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The reverse osmosis membrane production method is as follows:

[0026] 1. Preparation of aqueous phase solution: Add 3kg of m-phenylenediamine, 0.5kg of sodium dodecylbenzenesulfonate, and 4kg of N-methylpyrrolidone to 92.5kg of water, and stir to obtain an aqueous phase solution;

[0027] 2. Preparation of oil phase solution: Dissolve 0.1 kg of trimesoyl chloride in 100 kg of naphtha, stir well to obtain oil phase solution;

[0028] 3. First, coat the water-phase solution on the bottom membrane of the polysulfone support layer. After removing the excess solution on the surface with a low-pressure air knife, let the bottom membrane adsorbed with the water-phase solution pass through a closed space with a heating and ventilation system to control The internal temperature is 26°C, the relative humidity is 60%, and the time is 1min, so that the moisture on the surface of the bottom film is further volatilized. Keep it in an oven at ℃ for 5 minutes, dry the oil phase liqui...

Embodiment 2

[0031] The reverse osmosis membrane production method is as follows:

[0032] 1. Preparation of aqueous phase solution: Add 3kg of m-phenylenediamine, 0.5kg of sodium dodecylbenzenesulfonate, and 4kg of dimethyl sulfoxide to 92.5kg of water, and stir to obtain an aqueous phase solution;

[0033] 2, the preparation of oil phase solution: with embodiment 1;

[0034] 3. The film making method is the same as in Example 1.

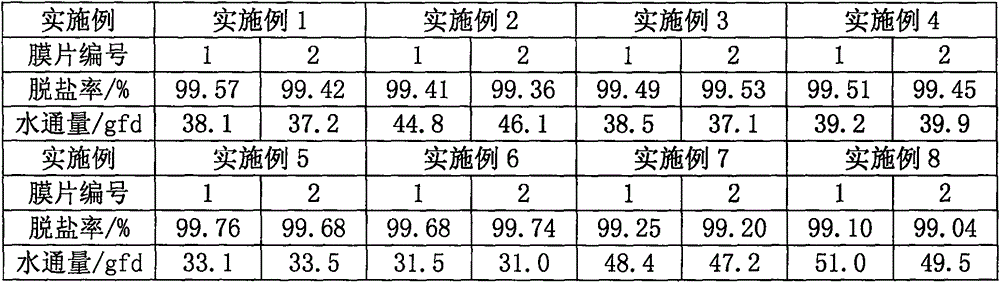

[0035] The membrane detection method is the same as in Example 1, and the results are shown in Table 1.

Embodiment 3

[0037] The reverse osmosis membrane production method is as follows:

[0038] 1. Preparation of aqueous phase solution: Add 3kg m-phenylenediamine, 0.5kg sodium dodecylbenzenesulfonate, 3kg N-methylpyrrolidone, 1kg dimethyl sulfoxide to 92.5kg water, stir well to obtain aqueous phase solution ;

[0039] 2, the preparation of oil phase solution: with embodiment 1;

[0040] 3. The film making method is the same as in Example 1.

[0041] The membrane detection method is the same as in Example 1, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com