Flotation method of copper oxide ores

A technology for copper oxide ore and copper oxide, applied in flotation, solid separation and other directions, can solve the problems of precious resources, difficult processing and utilization, etc., and achieve the effect of improving recovery rate and concentrate quality, increasing value, and improving flotation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Using raw ore (containing Cu0.87%, S10.23%), the phase analysis of the raw ore shows that the distribution rate of copper oxide in copper minerals in copper minerals is 26.3%, and the rest is copper sulfide minerals. Copper sulfide ores are composed of brass Mainly mine. Other minerals are mainly pyrite, magnetite, etc., and main gangues are quartz, calcite, etc.

[0024] The flotation method of described copper oxide ore comprises the steps:

[0025] (1) Crushing and grinding: the crushed copper oxide ore is input into the grinding system for grinding treatment, and the ore after grinding is obtained. The ore particle size of the ore in the ore is -0.074mm. 80% of the total mineral products;

[0026] (2) Flotate the mineral material:

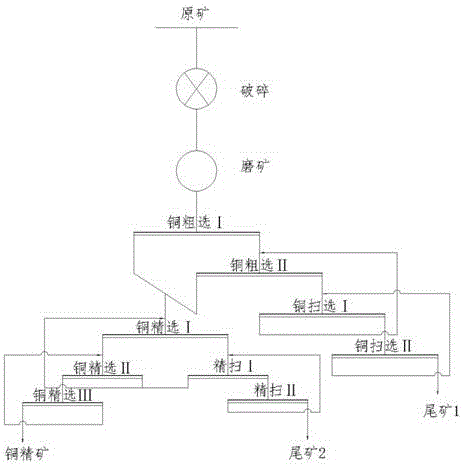

[0027] When the copper sulfide distribution rate in the raw ore is greater than 15%, the asynchronous flotation method is adopted, and the asynchronous flotation method includes copper sulfide flotation and copper oxide flotation, and...

Embodiment 2

[0032] Using the raw ore (containing Cu1.02%, S7.48%), the phase analysis of the raw ore shows that the distribution rate of copper oxide in copper minerals in copper minerals is 89.12%, and the rest is copper sulfide minerals. Mainly mine. Other minerals are mainly pyrite, magnetite, etc., and main gangues are quartz, calcite, etc.

[0033] The flotation method of described copper oxide ore comprises the steps:

[0034] (1) Crushing and grinding: the crushed copper oxide ore is input into the grinding system for grinding treatment, and the ore after grinding is obtained. The ore particle size of the ore in the ore is -0.074mm. 80% of the total mineral products;

[0035] (2) Flotate the mineral material:

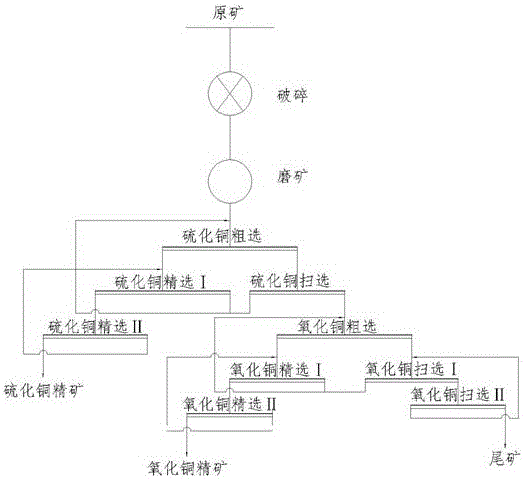

[0036] When the distribution rate of copper sulfide in the mineral material is less than 15%, the synchronous flotation method is adopted;

[0037] In the first copper roughing, add lime 2000g / t raw ore, adjust the pH value of the pulp to 10, and then add 5000g sodium su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com