Purification method of graphene oxide and graphene oxide

A purification method and graphene technology, applied in chemical instruments and methods, ion exchange column/bed methods, inorganic chemistry, etc., can solve the problems of poor purification effect and high content of impurity ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

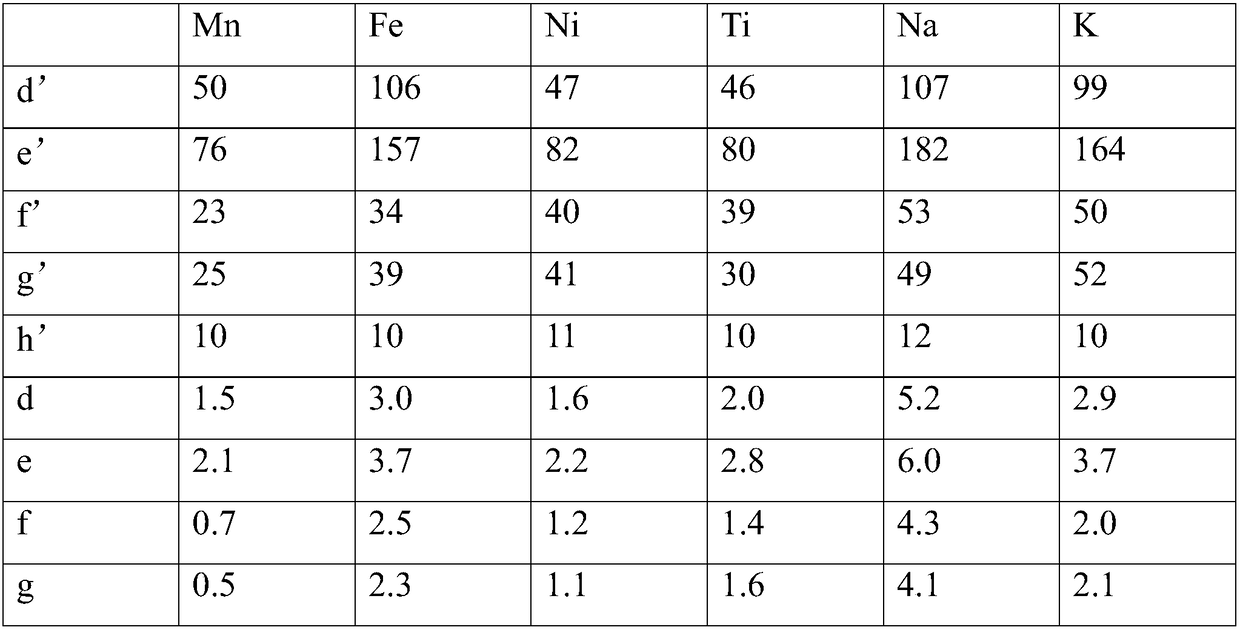

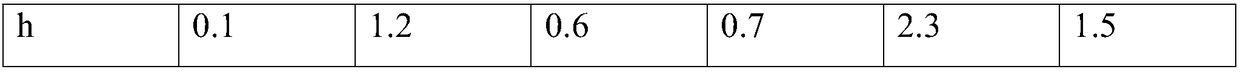

Examples

Embodiment 1

[0097] ion exchange purification

[0098] B1, configuring the graphene oxide to be purified into a graphene oxide solution with a solid content of 0.2%;

[0099] B2, the hydrogen type strong acid cation resin and the hydroxide type strong base anion exchange resin are loaded into the ion exchange column, the cation exchange resin is set in the upper section, and the anion exchange resin is set in the lower section;

[0100] B3, sending the graphene oxide solution into the ion exchange column; the flow rate of the graphene oxide solution is 200L / h.

Embodiment 2

[0102] ion exchange purification

[0103] B1, configuring the graphene oxide to be purified into a graphene oxide solution with a solid content of 0.5%;

[0104] B2, the hydrogen type weak acid cation resin and the hydroxide type weak base anion exchange resin are loaded into the ion exchange column, the cation exchange resin is set in the upper section, and the anion exchange resin is set in the lower section;

[0105] B3, sending the graphene oxide solution into the ion exchange column; the flow rate of the graphene oxide solution is 50L / h.

Embodiment 3

[0107] ion exchange purification

[0108] B1, configuring the graphene oxide to be purified into a graphene oxide solution with a solid content of 0.3%;

[0109] B2, the hydrogen type weak acid cation resin and the hydroxide type weak base anion exchange resin are loaded into the ion exchange column, the cation exchange resin is set in the upper section, and the anion exchange resin is set in the lower section;

[0110] B3, sending the graphene oxide solution into the ion exchange column; the flow rate of the graphene oxide solution is 120L / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com