A kind of synthetic method of high isoprene content butyl rubber

A technology of high isoprene and butyl rubber, which is applied in the field of synthesizing high isoprene content butyl rubber, can solve the problems of excessive heat release, etc., to solve the problem of excessive heat release, inhibit activity and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Catalyst preparation

[0041] The reaction flask was pumped and filled with nitrogen three times. Add 90ml of isopentane to a 1000ml polymerization bottle under the protection of high-purity nitrogen, add 200μl of water at room temperature, stir to make it evenly mixed, add 20ml of ethylaluminum sesquichloride, then add 1g of triethylaluminum and 1g of nitroethane, and aged at this temperature for 60min, thereby making a catalyst solution. The whole process was carried out in a glove box under a dry nitrogen atmosphere.

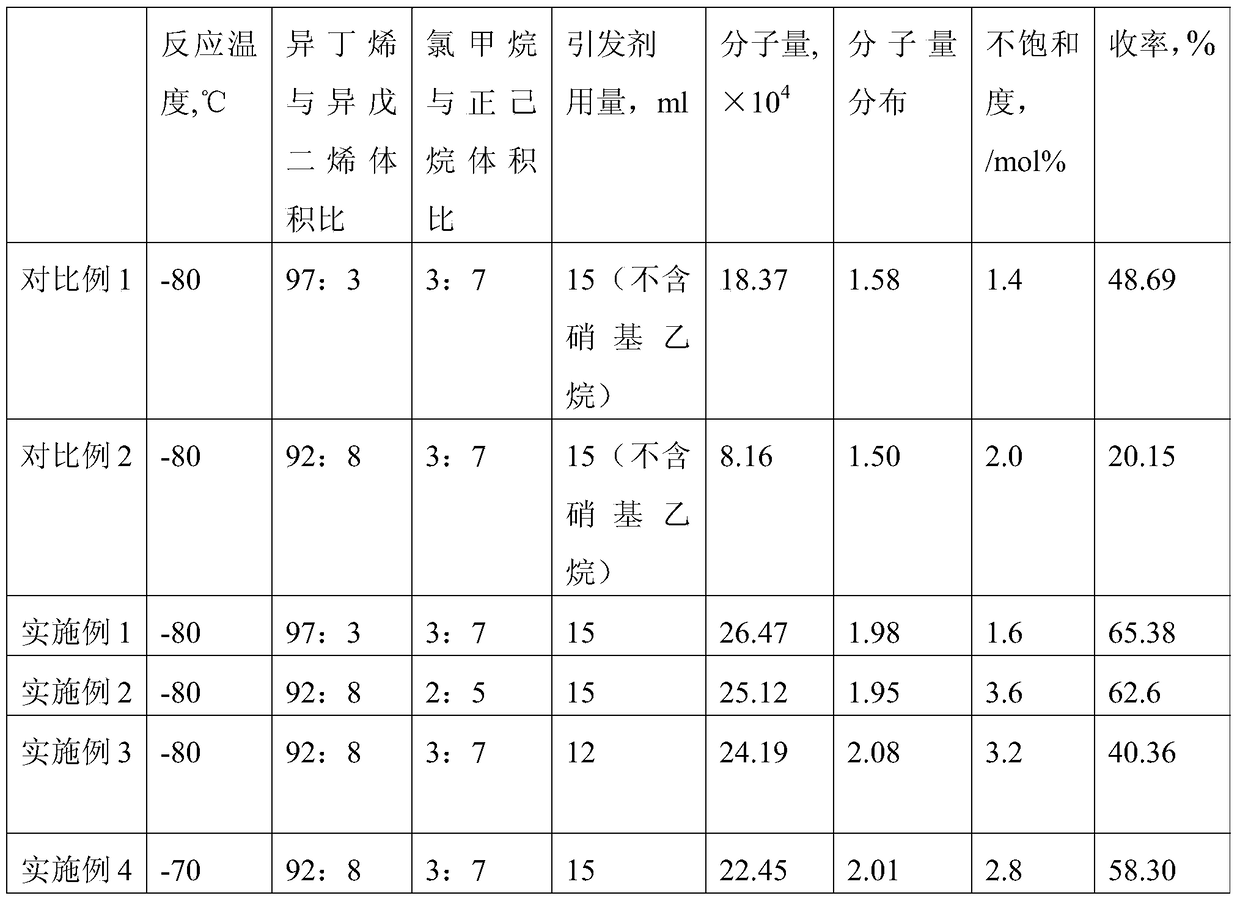

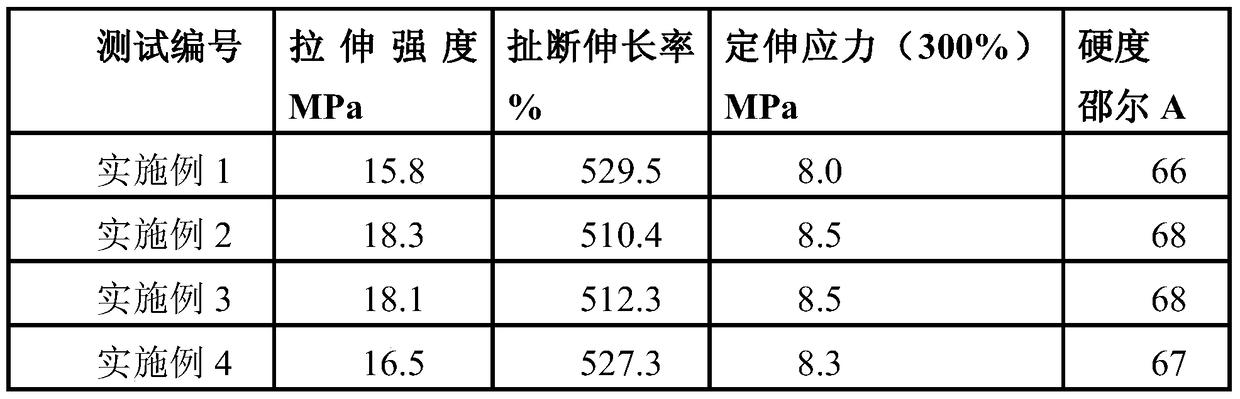

Embodiment 1

[0043] Add 200ml of monomer mixture (volume ratio of isobutylene to isoprene: 97:3) into 200ml of pre-prepared solvent (volume ratio of methyl chloride to n-hexane: 3:7) at -80°C, and then stir 15 ml of the catalyst described in Example 1 were added in the case of . After 30 min, 8 ml of methanol solution was added to terminate the reaction. The polymer was precipitated with 100 ml of methanol, then washed with water, filtered and dried at 50°C to constant weight. Butyl rubber polymer yield is 65.38%, and the number average molecular weight of product is 26.47 * 10 4 g / mol, the molecular weight distribution index is 1.98, and the degree of unsaturation is 1.6.

Embodiment 2

[0045] Except that the volume ratio of the polymerization solvent methyl chloride to n-hexane is 2:5; the volume ratio of isobutylene to isoprene is 92:8, the steps of Example 2 are repeated, and the yield of butyl rubber polymer is 62.6%. The number average molecular weight is 25.12×10 4 g / mol, the molecular weight distribution index is 1.95, and the degree of unsaturation is 3.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com