Supported Catalyst for Synthesis of Low Molecular Weight Polyethylene Oxide and Its Preparation and Application

A supported catalyst and polyethylene oxide technology, which is applied in the field of supported catalysts and preparations for the synthesis of low molecular weight polyethylene oxide, can solve the problems of not being able to use PEO, achieve low cost, reduce fluctuations, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of preparation method for the supported catalyst of synthesizing low molecular weight polyoxyethylene comprises the following steps:

[0041] (1) Pretreatment of nanomaterials

[0042] A certain amount of hydrophilic silica was treated at 50°C for 6 hours.

[0043] (2) Supporting of catalyst

[0044] Weigh 5g of the above-mentioned treated hydrophilic silica and add it into a 1L reaction bottle, then slowly add 5.0g of metallic calcium (purity>99.5%) into 200mL of industrial grade liquid ammonia at -40°C to generate calcium Ammonium complex, after the reaction is complete, add the modifying agent that is dissolved in 300mL n-heptane by acetonitrile, propylene oxide (the molar ratio with the calcium element in the calcium ammonium complex is respectively 0.5 and 1), fully After the reaction, the residual liquid ammonia was volatilized at room temperature, and finally the temperature was raised to 60°C for aging. After condensing and refluxing for 1 hour, a slurr...

Embodiment 2

[0048] (1) Pretreatment of nanomaterials

[0049] Except that the calcining temperature of a certain amount of hydrophilic silica was changed to 300° C., other operations were the same as in Example 1.

[0050] (2) Supporting of catalyst

[0051] The loading preparation process is the same as in Example 1.

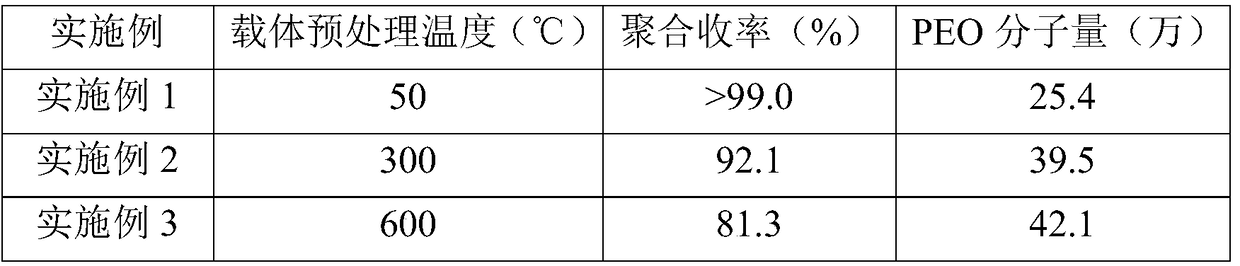

[0052] (3) Polymerization of ethylene oxide

[0053] The reactor used for slurry polymerization is a 10L magnetically coupled reactor with stirring, which is fed in a batch reaction mode. First, the supported catalyst prepared in step (2) was added in one go, and then 2000 mL of n-heptane and 800 g of ethylene oxide were added respectively. Wherein, the polymerization reaction is carried out at 5° C. to 25° C. for 15 hours to obtain a polyethylene oxide product. The polyethylene oxide prepared by the supported catalyst is all white powder particles, and the polymerization results are shown in Table 1.

Embodiment 3

[0055] (1) Pretreatment of nanomaterials

[0056] Except that the calcining temperature of a certain amount of hydrophilic silica was changed to 600° C., other operations were the same as in Example 1.

[0057] (2) Supporting of catalyst

[0058] The loading preparation process is the same as in Example 1.

[0059] (3) Polymerization of ethylene oxide

[0060] The reactor used for slurry polymerization is a 10L magnetically coupled reactor with stirring, which is fed in a batch reaction mode. First, the supported catalyst prepared in step (2) was added in one go, and then 2000 mL of n-heptane and 800 g of ethylene oxide were added respectively. Wherein, the polymerization reaction is carried out at 5° C. to 25° C. for 13 hours to obtain a polyethylene oxide product. The polyethylene oxide prepared by the supported catalyst is all white powder particles, and the polymerization results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com