Method for preparing hydrocarbon biodiesel from biomass

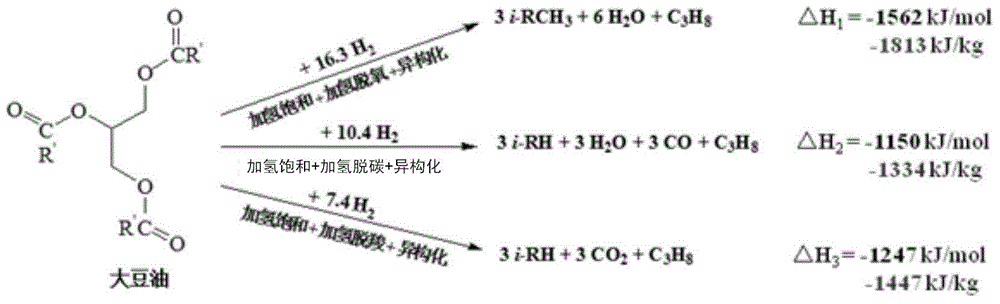

A technology of biodiesel and biomass, which is applied in the treatment of hydrocarbon oil, biofuel, and biological raw materials. It can solve the problems of high freezing point, low octane number of light fractions, and inability to be used as gasoline, so as to improve low-temperature performance and relieve Exothermic Effect of Hydrogenation Reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

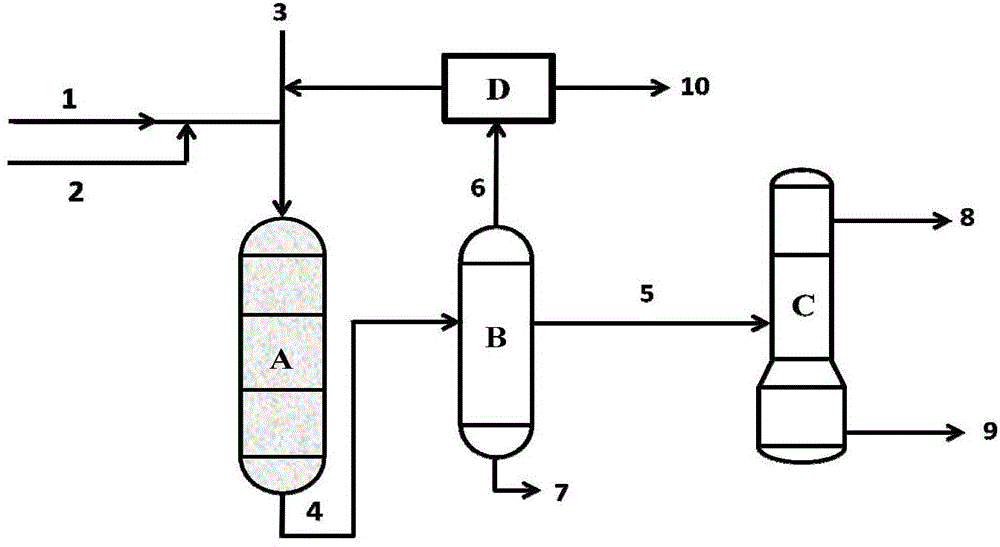

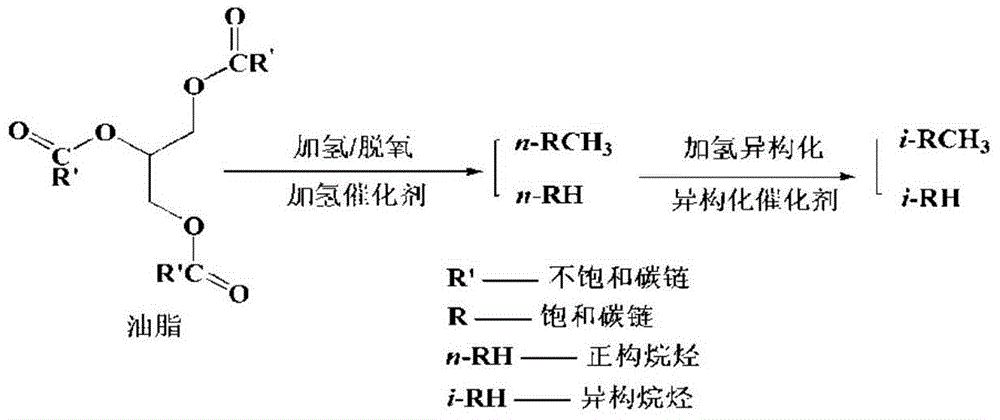

Method used

Image

Examples

Embodiment 1

[0066] The volume ratio of soybean oil to Fischer-Tropsch synthetic wax middle distillate (distillation range 150-450°C) is 2:1, and the two are mixed evenly to make raw materials. Weigh 90g of Pt / SAPO-11 catalyst (100mL, particle size of 10-20 mesh) with a Pt loading of 2wt.%, and put it in a stainless steel fixed-bed reactor with an inner diameter of 25mm and a tube length of 1.5m. Both ends are filled with 20-40 mesh quartz sand. The reaction conditions are: 340°C, 6.0MPa, LHSV for 1h -1 , the ratio of the volume of hydrogen to the sum of the volume of Fischer-Tropsch synthetic wax middle distillate and oil is 3000NL / NL. Samples were taken after 24 h of reaction. The liquid hydrocarbon product and water are separated by liquid separation, and the liquid hydrocarbon product is subjected to atmospheric distillation to separate naphtha (fraction less than 150° C.) to obtain biodiesel product (150-450° C. fraction). The liquid hydrocarbon products were analyzed by GC and GC-...

Embodiment 2

[0069] The volume ratio of soybean oil to Fischer-Tropsch synthetic wax middle distillate (distillation range 150-450°C) is 1:1, and the two are mixed evenly to make raw materials. Weigh 90g of Pt / SAPO-11 catalyst (100mL, particle size of 10-20 mesh) with a Pt loading of 2wt.%, and put it in a stainless steel fixed-bed reactor with an inner diameter of 25mm and a tube length of 1.5m. Both ends are filled with 20-40 mesh quartz sand. The reaction conditions are: 340°C, 6.0MPa, LHSV for 1h -1 , the ratio of the volume of hydrogen to the sum of the volume of Fischer-Tropsch synthetic wax middle distillate and oil is 3000NL / NL. Samples were taken after 24 h of reaction. The liquid hydrocarbon product and water are separated by liquid separation, and the liquid hydrocarbon product is subjected to atmospheric distillation to separate naphtha (fraction less than 150° C.) to obtain biodiesel product (150-450° C. fraction). The liquid hydrocarbon products were analyzed by GC and GC-...

Embodiment 3

[0072] The volume ratio of soybean oil to Fischer-Tropsch synthetic wax middle distillate (distillation range 150-450°C) is 1:2, and the two are mixed evenly to make raw materials. Weigh 90g of Pt / SAPO-11 catalyst (100mL, particle size of 10-20 mesh) with a Pt loading of 2wt.%, and put it in a stainless steel fixed-bed reactor with an inner diameter of 25mm and a tube length of 1.5m. Both ends are filled with 20-40 mesh quartz sand. The reaction conditions are: 350°C, 6.0MPa, LHSV for 1h -1 , the ratio of the volume of hydrogen to the sum of the volume of Fischer-Tropsch synthetic wax middle distillate and oil is 3000NL / NL. Samples were taken after 24 h of reaction. The liquid hydrocarbon product and water are separated by liquid separation, and the liquid hydrocarbon product is subjected to atmospheric distillation to separate naphtha (fraction less than 150° C.) to obtain biodiesel product (150-450° C. fraction). The liquid hydrocarbon products were analyzed by GC and GC-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solidifying point | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com