Streptomyces hygroscopicus for producing validamycin and application of streptomyces hygroscopicus

A technology of Streptomyces hygroscopicus, Jinggangmycin, applied in bacteria, microorganism-based methods, microorganisms, etc., can solve problems such as poor product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Mutagenesis and screening of embodiment 1 bacterial strain

[0010] 1. Using ion beam mutagenesis to treat the bacterial suspension to obtain mutant strains

[0011] Take an appropriate amount of slant cells or spores produced by Jinggangmycin, and place them in sterile water containing glass beads, so that the concentration of cells or spores is at 10 6 ~10 8 per ml, shake well to disperse. Draw 0.2 ml of the suspension into a petri dish with a diameter of 9 cm, spread it evenly with a stick, and blow it in an aseptic wind for 0.5 hours in an ultra-clean bench until it dries into plaques. The nitrogen ion energy is 7Kev, and the dose is 5×10 13 , 10×10 13 , 15×10 13 , 20×10 13 , 25×10 13 Mutagenesis was carried out at five levels, each experiment was treated accordingly, and the shake flask was the same as the starting strain, and the mutagenic dose was determined to be 10×10 through repeated experiments. 13 When N+ / CM, the positive mutation rate of the strain ...

Embodiment 2

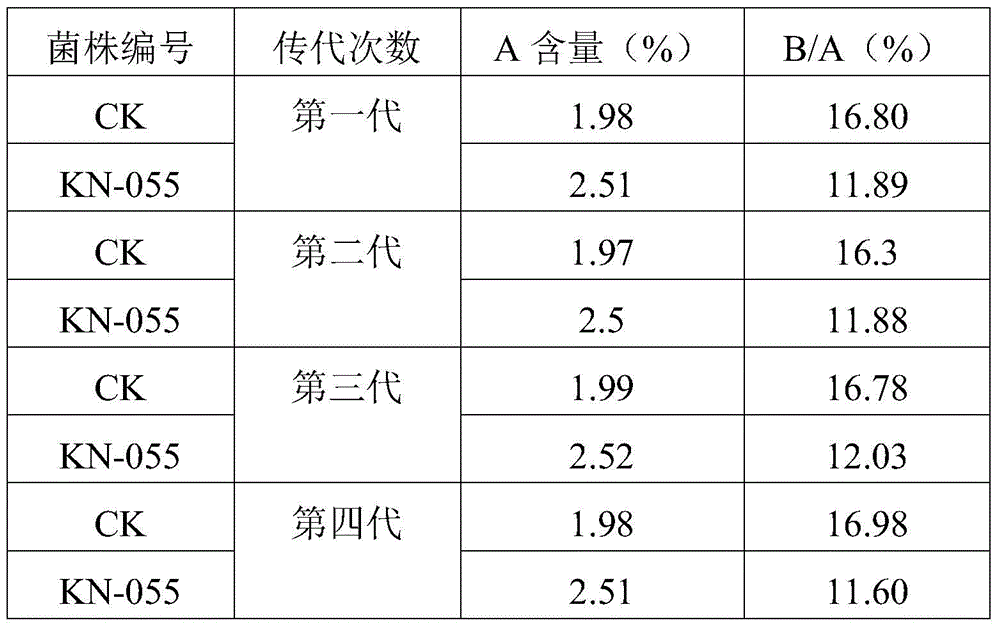

[0026] Embodiment 2 Utilizes the experimental research of bacterial strain production Jinggangmycin

[0027] 1) Strain activation

[0028] The preserved Streptomyces hygroscopicus KN-055 strain was activated on Gaoshi No. 1 slant medium, cultured at 28°C for 7 days, and the bacterial lawn was washed with sterile water to obtain a seed suspension;

[0029] 2) Secondary seed cultivation

[0030] Put the seed suspension obtained in step 1) into a seed fermenter, 200rpm, and cultivate at 37°C for 22-24hr. The composition of the seed fermentation medium is: 5% corn flour, 2.4% starch, 0.5% soybean meal, 0.05% NaCl, CaCO 3 0.05%, KH 2 PO 4 0.05%, the balance is water, and the content of each component is according to the mass volume ratio;

[0031] 3) Fermentation culture

[0032] Transfer the fermented seed liquid obtained after step 2) into a large fermenter for cultivation, set the fermentation parameters as follows: aeration ratio 1:1, stirring speed 420rpm, fermentation te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com