Passivation lithium powder and preparing method thereof, positive electrode material with addition of passivation lithium powder and battery

A positive electrode material and lithium passivation technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as battery performance hazards, failures, and impacts on battery performance, and achieve large-scale commercial applications and high energy density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The present invention also provides a preparation method of passivated lithium powder, comprising:

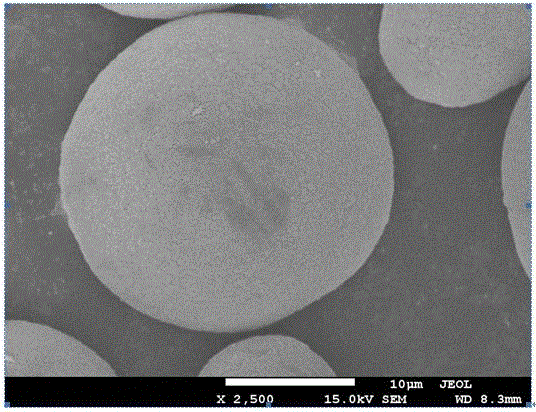

[0019] (1) Metal lithium is added to the first solvent under an inert atmosphere, the first solvent and metal lithium do not react, heated until the metal lithium melts, stirred to disperse the molten metal lithium, cleaned and dried after cooling, to obtain lithium powder particles.

[0020] (2) Under an inert atmosphere, the metal salt is added in the second solvent to obtain a solution, the second solvent does not react with lithium metal, the lithium powder particles obtained in step (1) are added to the solution, and the lithium powder particles react with the metal salt In situ reduction reaction, the reaction product is washed and dried to obtain passivated lithium powder.

[0021] Preferably, the reaction time in the step (2) is 1-60min. By controlling the reaction time, a dense metal layer can be coated on the surface of the lithium powder particles. By control...

Embodiment 1

[0036](1) Add 25g of battery-grade lithium powder particles into 250mL of mineral oil, and the reaction is carried out in a stainless steel reactor, which is sealed and protected by argon. Heat the above reaction solution to 180°C, and apply slow stirring at a speed of 100rpm during the heating process, until the lithium powder particles are completely dissolved; when the temperature rises to 180°C and the lithium is completely dissolved, increase the stirring speed to 10000rpm, and stir for 10 minutes, The heating device was removed, and the reaction vessel was placed in a mixture of ice and water. While maintaining high-speed stirring, the reaction liquid in the vessel was rapidly cooled. When the temperature of the reaction solution drops to room temperature, stop stirring, filter the reaction solution, separate, and wash with hexane for 4 times, then dry it in a positive air drying oven at 45°C for 2 hours and take it out for use;

[0037] (2) 15.00gCu(CF 3 SO 3 ) 2 Dis...

Embodiment 2

[0039] Different from Example 1, 12.00gCu(ClO 4 ) 2 Dissolve in 100g EC, add the prepared EC+Cu(ClO 4 ) 2 In the mixed solution, after stirring for 15 minutes, the copper-coated lithium powder was separated, washed by DEC three times, and then dried in an argon atmosphere. The whole process was carried out in an argon atmosphere to obtain passivated lithium powder A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com