Laying-chicken feed

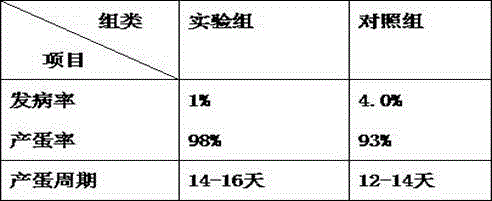

A technology of feed and raw materials for laying hens, which is applied in the field of chicken feed, can solve the problems of calcium-phosphorus ratio, amino acid ratio, energy and protein ratio imbalance, lower feed utilization rate, toxic and harmful substances, etc., to improve feed conversion rate, Effect of improving quality and increasing appetite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A feed for laying hens, which is mainly prepared by pulverizing and mixing the following raw materials according to the weight ratio:

[0022] Corn 200kg, soybean meal 80kg, cotton meal 350kg, mugwort leaves 10kg, hawthorn 15kg, atractylodes 9kg, red dates 25kg, lily 10kg, grape seeds 22kg, salad oil 10kg, stone powder 25kg, fish meal 2kg, bone meal 100kg, hemoglobulin powder 50kg, corn protein Powder 100kg, food attractant 5kg, calcium hydrogen phosphate 2kg, salt 1kg, lysine 10kg, methionine 10kg, lysine slag 50kg, additive 10kg.

[0023] The preparation method of the laying hen feed, its preparation steps are as follows:

[0024] (1) Mix corn, soybean meal, cotton meal and grape seed according to the ratio and process it into powder;

[0025] (2) Crush mugwort leaves, hawthorn, atractylodes rhizome, red dates, and lilies, add water and boil them into pulp;

[0026] (3) Pour all the remaining ingredients together with the products of step (1) and step (2) into the f...

Embodiment 2

[0028] A feed for laying hens, which is mainly prepared by pulverizing and mixing the following raw materials according to the weight ratio:

[0029] Corn 300kg, soybean meal 120kg, cotton meal 380kg, mugwort leaves 11kg, hawthorn 18kg, atractylodes 10kg, red dates 28kg, lily 11kg, grape seeds 23kg, salad oil 15kg, stone powder 40kg, fish meal 3kg, bone meal 125kg, hemoglobulin powder 75kg, corn protein Powder 150kg, food attractant 5kg, calcium hydrogen phosphate 5kg, salt 2kg, lysine 18kg, methionine 12kg, lysine slag 75kg, additive 12kg.

[0030] The preparation method of the laying hen feed, its preparation steps are as follows:

[0031] (1) Mix corn, soybean meal, cotton meal and grape seed according to the ratio and process it into powder;

[0032] (2) Crush mugwort leaves, hawthorn, atractylodes rhizome, red dates, and lilies, add water and boil them into pulp;

[0033] (3) Pour all the remaining ingredients together with the products of step (1) and step (2) into the...

Embodiment 3

[0035] A feed for laying hens, which is mainly prepared by pulverizing and mixing the following raw materials according to the weight ratio:

[0036] Corn 400kg, soybean meal 150kg, cotton meal 400kg, mugwort leaves 12kg, hawthorn 20kg, herb 12kg, red dates 30kg, lily 12kg, grape seeds 24kg, salad oil 20kg, stone powder 60kg, fish meal 3kg, bone meal 150kg, hemoglobulin powder 100kg, corn protein Powder 200kg, food attractant 6kg, calcium hydrogen phosphate 8kg, salt 2kg, lysine 25kg, methionine 15kg, lysine slag 100kg, additive 15kg.

[0037] The preparation method of the laying hen feed, its preparation steps are as follows:

[0038] (1) Mix corn, soybean meal, cotton meal and grape seed according to the ratio and process it into powder;

[0039] (2) Crush mugwort leaves, hawthorn, atractylodes rhizome, red dates, and lilies, add water and boil them into pulp;

[0040] (3) Pour all the remaining ingredients together with the products of step (1) and step (2) into the feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com