Method for preparing charcoal through microwaves

A biochar and microwave technology, applied in chemical instruments and methods, water/sludge/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of high energy consumption, low efficiency and long heating time, and achieve the loss coefficient Large, speed up the reaction rate, save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

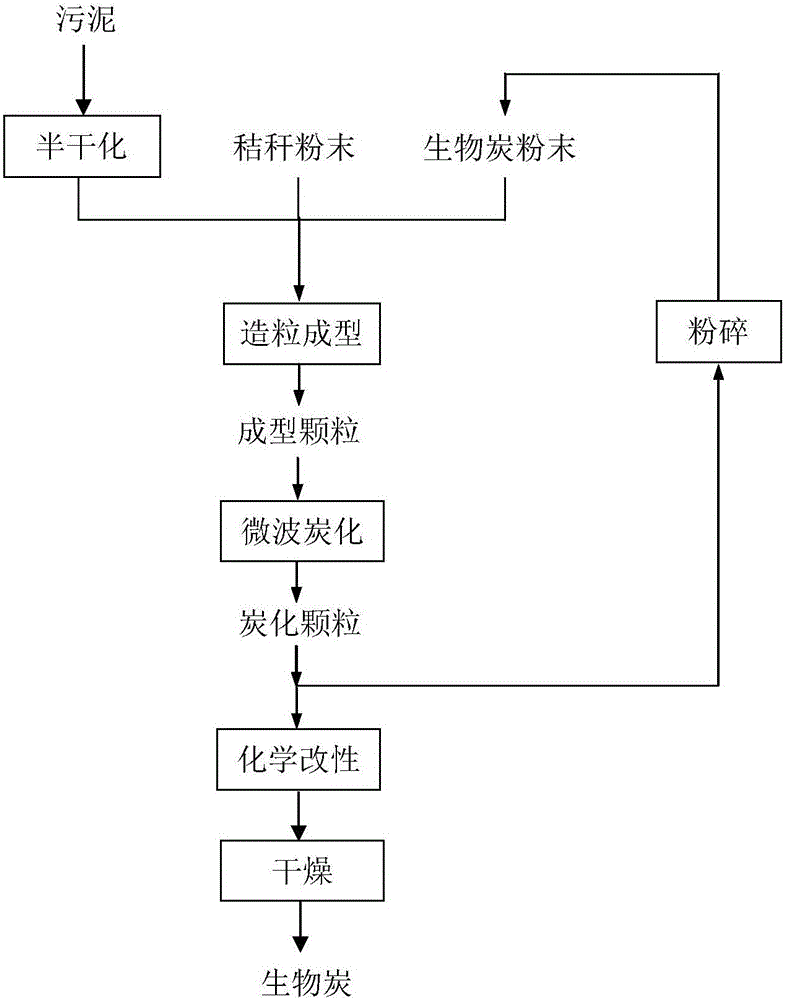

[0020] A kind of method adopting microwave preparation biochar, adopts following steps:

[0021] 1) Mix 25% semi-dried sludge, 65% biological straw powder and 10% biochar powder, and then granulate to obtain shaped granules. The moisture content of the semi-dried sludge is 40%.

[0022] 2) placing the formed particles in a microwave oven for carbonization to obtain carbonized particles. The specific process is as follows: put the formed particles into a microwave oven, set the microwave power to 1200W, and set the carbonization time to 7 minutes. After passing nitrogen gas at a rate of 1 L / min for 15 minutes, start the microwave oven to start carbonization. After the carbonization is completed, carbonized particles are obtained. .

[0023] 3) Divide the carbonized particles into two unequal parts, and obtain the biochar powder described in step 1) after pulverization of a small part of the carbonized particles as a raw material and return to the step 1), and put most of the ...

Embodiment 2

[0028] A kind of method adopting microwave preparation biochar, adopts following steps:

[0029] 1) Mix 30% semi-dried sludge, 60% biological straw powder and 10% biochar powder, and then granulate to obtain shaped granules. The moisture content of the semi-dried sludge is 50%.

[0030] 2) placing the formed particles in a microwave oven for carbonization to obtain carbonized particles. The specific process is as follows: put the molded particles into a microwave oven, set the microwave power to 1800W, and set the carbonization time to 5 minutes. After passing nitrogen gas at a rate of 1L / min for 15 minutes, start the microwave oven to start carbonization. After the carbonization is completed, carbonized particles are obtained. .

[0031] 3) Divide the carbonized particles into two unequal parts, and obtain the biochar powder described in step 1) after pulverizing a small part of the carbonized particles as a raw material to return to the step 1), and put most of the carboni...

Embodiment 3

[0036] A kind of method adopting microwave preparation biochar, adopts following steps:

[0037] 1) Mix 30% semi-dried sludge, 55% biological straw powder and 15% biochar powder, and then granulate to obtain shaped granules. The moisture content of the semi-dried sludge is 45%.

[0038] 2) placing the formed particles in a microwave oven for carbonization to obtain carbonized particles. The specific process is as follows: put the shaped particles into a microwave oven, set the microwave power to 1400W, and the carbonization time to 6 minutes, and then feed nitrogen gas at a rate of 1L / min for 15 minutes, then start the microwave oven to start carbonization, and obtain carbonized particles after the carbonization is completed. .

[0039] 3) Divide the carbonized particles into two unequal parts, and obtain the biochar powder described in step 1) after pulverizing a small part of the carbonized particles as a raw material to return to the step 1), and put most of the carbonize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com