Visual guidance automatic skew detection type leather laser cutting system

An automatic deviation correction and vision-guided technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high production cost, affecting the quality of embroidery and shoes and clothing, and long production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

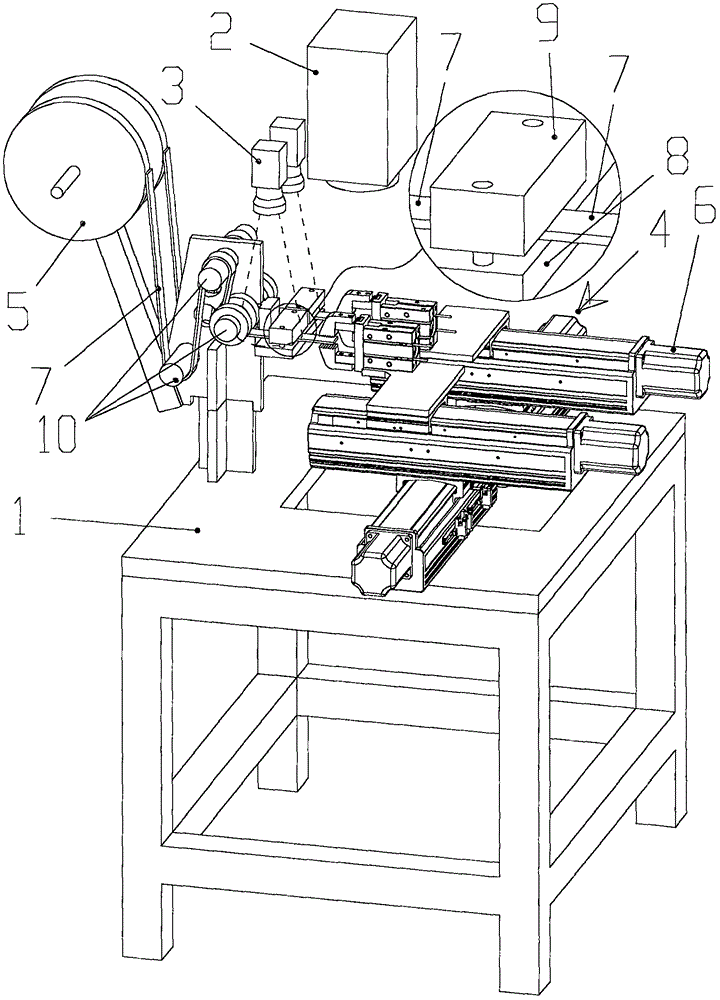

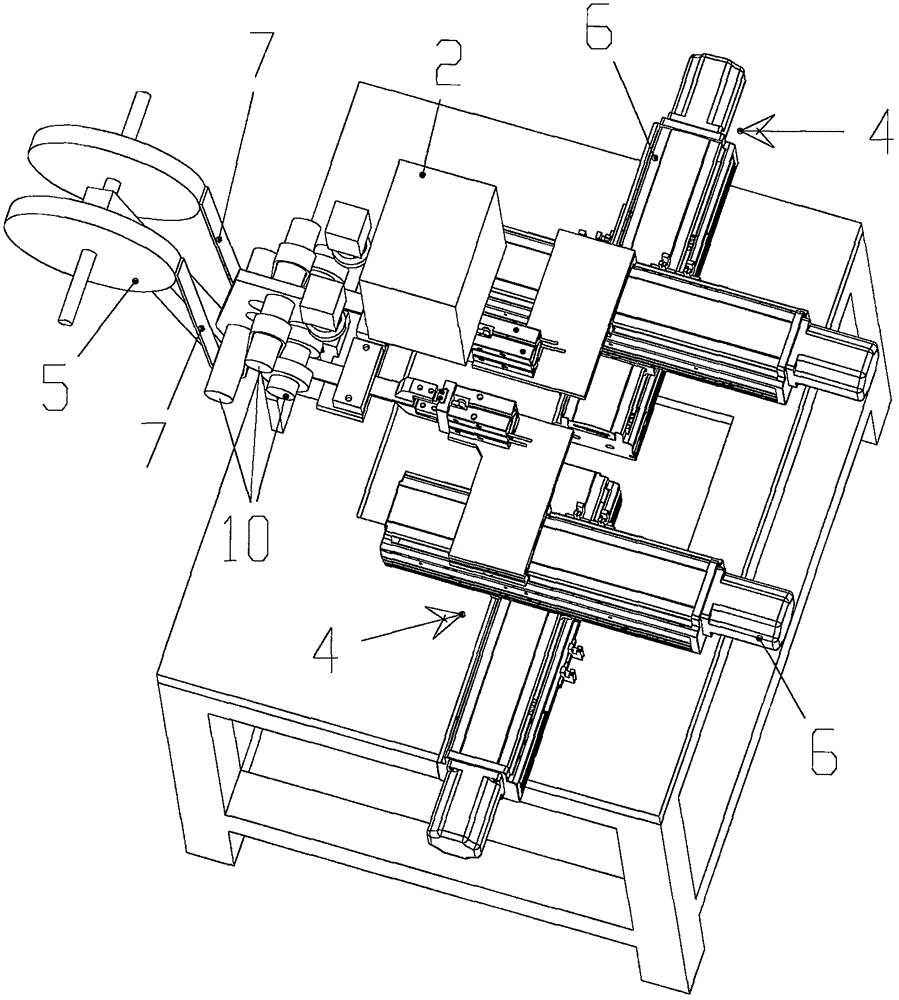

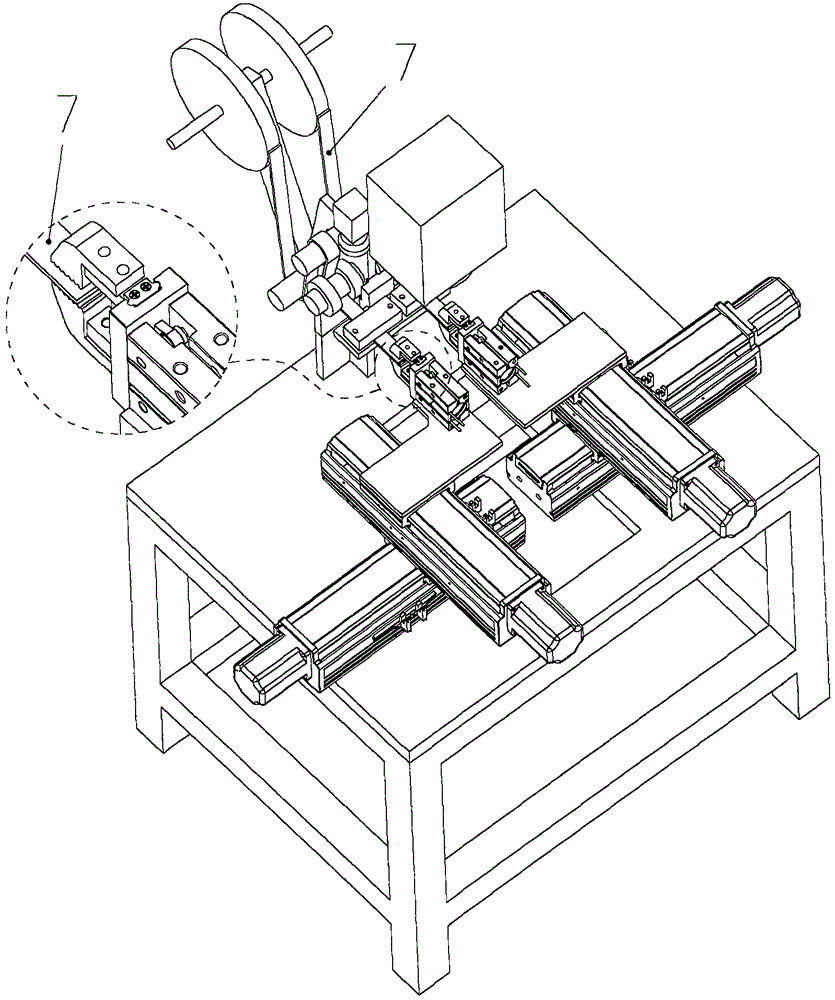

[0031] The embodiments of the present invention will now be described with reference to the accompanying drawings, in which similar element numbers represent similar elements. As mentioned above, the present invention provides a robot-assisted full-automatic leather laser cutting equipment. The leather is pulled by a two-axis robot for feeding, and the long strip of leather wound on the reel is adjusted by the laser marking machine. The length is cut, and various patterns are cut on the end face to realize the unmanned operation of leather cutting; the industrial camera collects the position of the leather, and the two-axis robot corrects the position of the leather under the guidance of the industrial camera while pulling the leather. Keep the leather in the center at all times.

[0032] figure 1 , 2 , 3 is a schematic diagram of the structure of the vision-guided automatic correction leather laser cutting system of the present invention, Figure 4 It is a schematic structural d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com