Metal-doped hollow mesoporous silicon oxide nanosphere and preparation method thereof

A mesoporous silicon oxide and metal doping technology, which is applied in the direction of silicon oxide, silicon dioxide, nanotechnology for materials and surface science, etc., can solve the problems of cumbersome steps and difficult to effectively control the size of hollow spheres, and achieve the synthesis The process steps are simple, the raw materials are widely available and cheap, and the operability is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

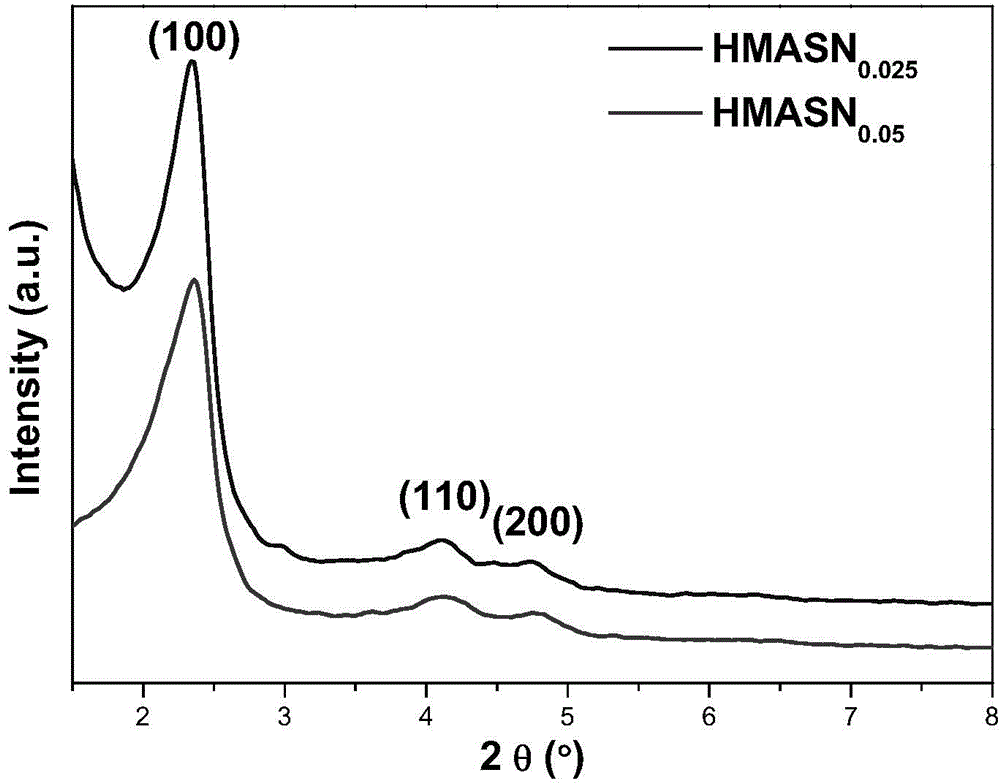

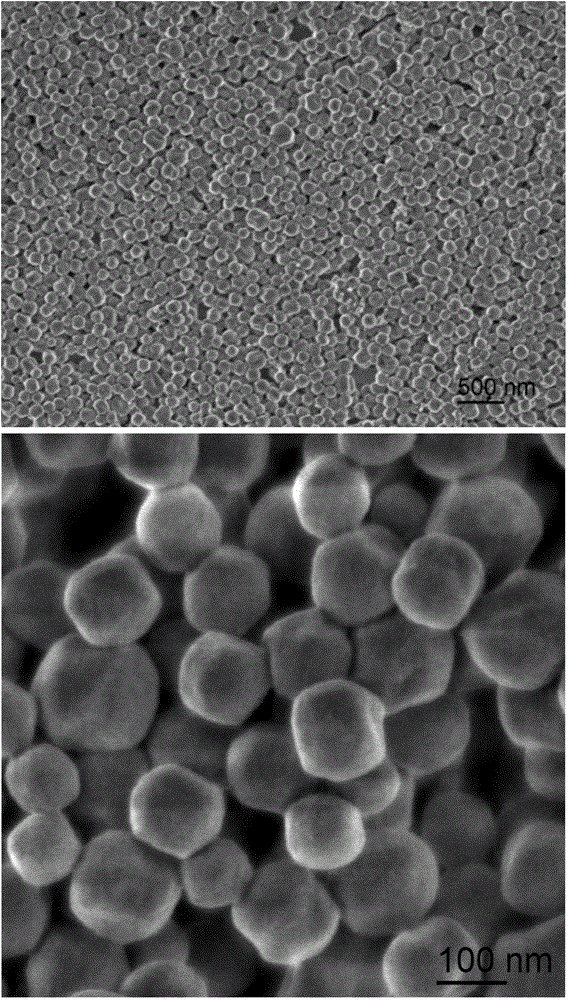

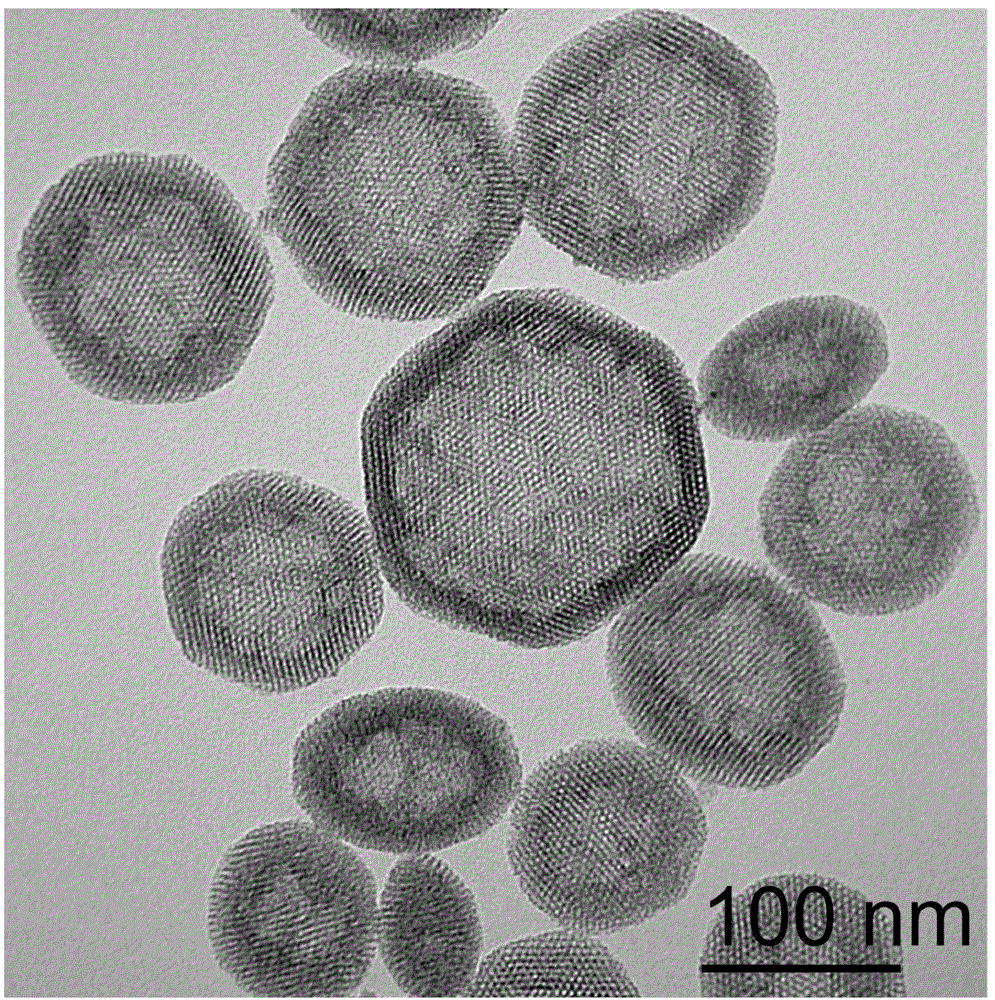

[0031] Example 1 Synthesis of aluminum-doped hollow mesoporous silica nanospheres

[0032] Ethyl orthosilicate is used as the silicon source, and aluminum isopropoxide is used as the aluminum source. The surfactant CTAB was added into deionized water, adjusted to pH = 11.4 with concentrated ammonia water (25 wt%), stirred and dissolved in a water bath at 50°C. Prepare dilute ethanol solution A of tetraethyl orthosilicate, the concentration is 0.2mol L -1 ; Concentrated ethanol solution B of tetraethyl orthosilicate, the concentration is 1.1mol L -1 ; The ethanol solution of aluminum isopropoxide, the concentration is 0.065mol L -1 or 0.0325mol L -1 (Correspondingly, Al / Si=0.025, 0.05). Quickly add solution A to the above mixture under stirring, seal the reactor, stir for 5 hours, open the reactor, add solution B drop by drop, after vigorous stirring for 1 hour, add the ethanol solution of aluminum isopropoxide dropwise, and stir for 1 hour , 50 ° C water bath for 20 hours...

Embodiment 2

[0033] Example 2 Synthesis of tin-doped hollow mesoporous silica nanospheres

[0034] Ethyl orthosilicate is used as the silicon source, and tin tetrachloride is used as the tin source. The surfactant CTAB was added into deionized water, adjusted to pH = 11.4 with concentrated ammonia water (25 wt%), stirred and dissolved in a water bath at 50°C. Prepare dilute ethanol solution A of tetraethyl orthosilicate, the concentration is 0.2mol L -1 ; Concentrated ethanol solution B of tetraethyl orthosilicate, the concentration is 1.1mol L -1 ; Ethanol solution of tin tetrachloride, the concentration is 0.065mol L -1 (Correspondingly, Sn / Si=0.025). Quickly add solution A to the above mixture under stirring, seal the reactor, stir for 5 hours, open the reactor, add solution B drop by drop, after vigorous stirring for 1 hour, add the ethanol solution of tin tetrachloride drop by drop, and stir for 1 hour , standing in a 60°C water bath for 20 hours. The molar ratio of the raw mater...

Embodiment 3

[0035] Example 3 Synthesis of Niobium-doped Hollow Mesoporous SiO Nanospheres

[0036] Ethyl orthosilicate is used as the silicon source, and niobium pentachloride is used as the niobium source. The surfactant CTAB was added into deionized water, adjusted to pH = 11.4 with concentrated ammonia water (25 wt%), stirred and dissolved in a water bath at 50°C. Prepare dilute ethanol solution A of tetraethyl orthosilicate, the concentration is 0.2mol L -1 ; Concentrated ethanol solution B of tetraethyl orthosilicate, the concentration is 1.1mol L -1 ; Ethanol solution of niobium pentachloride, the concentration is 0.065mol L -1 (Correspondingly, Nb / Si=0.025). Quickly add solution A to the above mixture under stirring, seal the reactor, stir for 5 hours, open the reactor, add solution B drop by drop, after vigorously stirring for 2 hours, add niobium pentachloride ethanol solution drop by drop, stir for 1 hour , standing in a water bath at 130°C for 20 hours. The molar ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Cavity diameter | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com