Preparation method of molecular sieve of silicon dioxide of media pores

A mesoporous silica and molecular sieve technology, applied in the direction of silica, silicon oxide, and aluminum phosphate with molecular sieve characteristics, to achieve the effects of easy industrial production, lower production costs, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

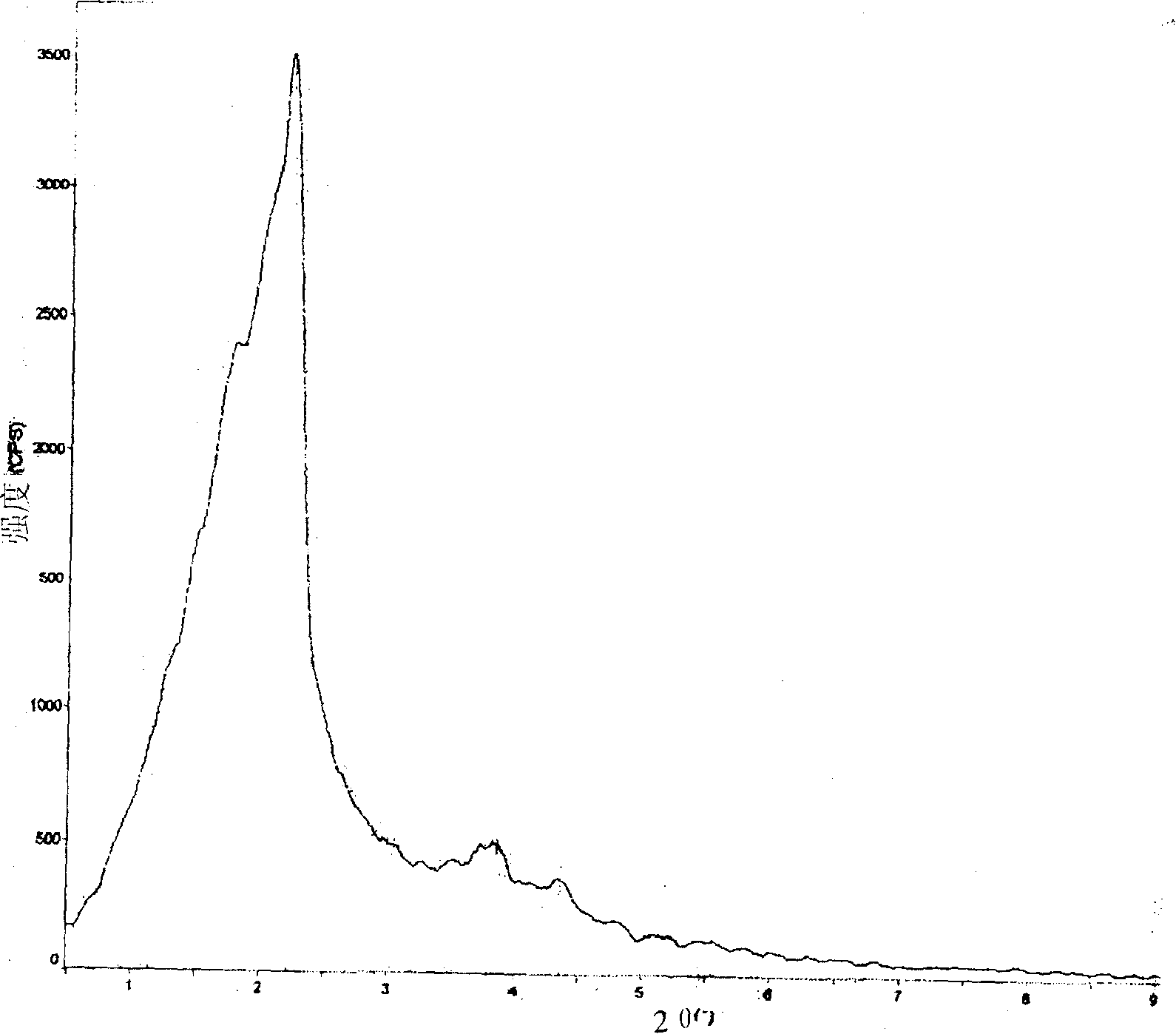

[0033] Dissolve 2.07g oxalic acid in 375g deionized water, add 1.75g ammonium metavanadate, 0.99g ammonium molybdate, 0.04g ammonium dihydrogen phosphate, 0.2g sodium acetate, heat to dissolve, and dissolve 223g normal Ethyl silicate, 98.4g of cetyltrimethylammonium bromide and 276g of ethanol were mixed, stirred for 5 hours, added ammonia water to make the pH 12, stirred for 20 hours, the reaction temperature was 30°C, the mixture was filtered and used to remove Wash with ionic water until neutral, dry at room temperature, and bake at 500°C for 5 hours. XRD spectrum see figure 1. In the XRD spectrum, the 2θ corresponding to the d value of 1.0nm is 8.842°, and the 2θ corresponding to the d value of 1.8nm is 4.909°. In this embodiment, the d value corresponding to the strongest line is 3.97 nm, the d value corresponding to the second strongest line is 2.28 nm, and the d value corresponding to the second strongest line is 2.02 nm. TEM pictures and electron diffraction patte...

Embodiment 2

[0035] Dissolve 2.07g oxalic acid in 80g deionized water, add 1.75g ammonium metavanadate, 0.99g ammonium molybdate, 0.04g ammonium dihydrogen phosphate, 0.03g cesium acetate, heat to dissolve, and dissolve 208g normal Ethyl silicate, 98.4g cetyltrimethylammonium bromide and 276g ethanol were mixed, stirred for 5 hours, added 20g sodium hydroxide, stirred for 80 hours, the reaction temperature was 18°C, the mixture was filtered, and deionized water was used to Wash until neutral, dry at room temperature and bake at 550°C for 4 hours. In this embodiment, the d value corresponding to the strongest line is 3.94 nm, and the d value corresponding to the second strongest line is 2.16 nm. BET surface area is 957m 2 / g, BJH pore size is 2.7nm.

Embodiment 3

[0037] Dissolve 9.46g oxalic acid in 375g deionized water, add 5.85g ammonium metavanadate, 4.2g ammonium molybdate, 0.2g ammonium dihydrogen phosphate, and dissolve 208g orthosilicate ethyl ester in 300g deionized water, 98.4g ten Mix hexaalkyltrimethylammonium bromide and 276g ethanol, stir for 0.5 hours, add 20g sodium hydroxide, stir for 1 hour, the reaction temperature is 18°C, filter the mixture, wash with deionized water until neutral, and dry at room temperature Then bake at 550°C for 3 hours. In this embodiment, the d value corresponding to the strongest line is 3.74 nm, and the d value corresponding to the second strongest line is 2.12 nm. BET surface area of 951m 2 / g, BJH pore size is 2.7nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com