Aqueous ceramic non-stick coating material for kitchenware surfaces and preparation method for aqueous ceramic non-stick coating material

A technology of non-stick coatings and ceramic coatings, applied in the field of materials, can solve the problems of high-end cookware and baking utensils that cannot meet the long-lasting non-stick and durability, the molecular structure of the surface state is easily destroyed, and reduce the hardness of ceramic coatings, etc., to achieve good coating Layer toughness and long-lasting non-stick performance, high hardness, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

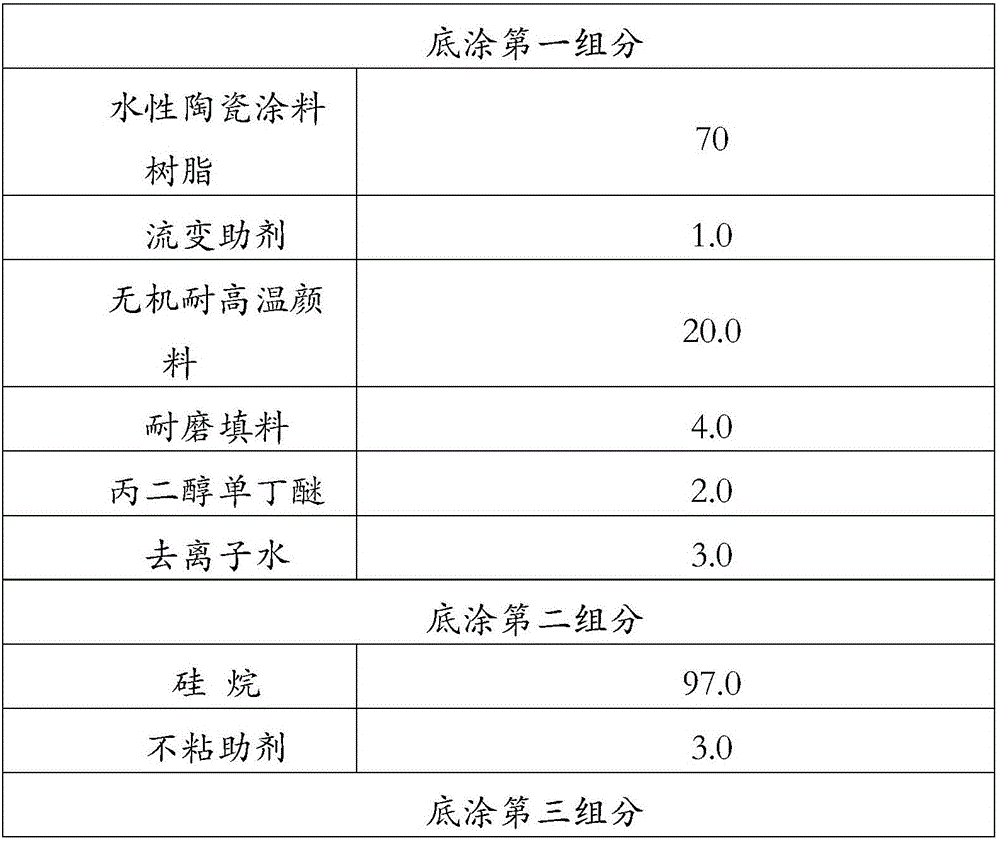

[0018] The invention discloses a method for preparing a water-based ceramic non-stick coating used on the surface of kitchen utensils, in particular a method for preparing a high-temperature-resistant water-based ceramic non-stick coating made of polytetrafluoroethylene on the surface of high-grade kitchen utensils, which comprises the following steps: its formula The ratio is by weight percentage:

[0019] The preparation of the primer includes first filtering the water-based ceramic coating resin into the stirring container with a 300-mesh nylon mesh, adding the rheological additive during stirring, and stirring and dispersing at a high speed of 1500-2000RPM for 15-20min, and then adding it while stirring Inorganic high temperature resistant pigment 15-20% and wear-resistant filler 0-5% and disperse evenly, then disperse at 1500-2000RPM at high speed for 10-15min, and finally pre-mix ethylene glycol monobutyl ether 1-3% and deionized water 1 Add -3% to the previous item and ...

Embodiment 1

[0031] Embodiment 1, 2, 3 and 4 middle primer aging processes are all: according to the ratio, the third component of the primer is first added to the second component of the primer and stirred evenly, and then the second and third groups Add it to the first component of the primer, stir and mature at 2000RPM for 2h.

[0032] The aging process of the top coat: Example The aging process of the top coat: according to the proportion, first add the fifth component of the top coat to the second component of the top coat and stir evenly, then mix the second component and the fifth component Add them together to the fourth component of the top coat, stir and mature at 2000RPM for 2h.

Embodiment 2

[0033] Embodiment two, the ripening process of three and four top coats: first add the second component of the top coat to the fourth component of the top coat and stir and ripen at a speed of 2000RPM for 2h., then add the fifth component of the top coat to 200 Add -500RPM speed into the second component and the fourth component and stir to disperse for 5-10min.

[0034] Use the IwataW-101 spray gun with a diameter of 1.3mm to spray the coatings that have been cured according to their respective curing processes, and use air spraying to spray evenly and pre-sandblast them (surface roughness Ra=2.5-3.5μm) and preheat to 50-60°C. For stainless steel frying pans, first spray the base coat, and then wet-on-wet spray the top coat, so that the thickness of the coating film is between 40-45 μm.

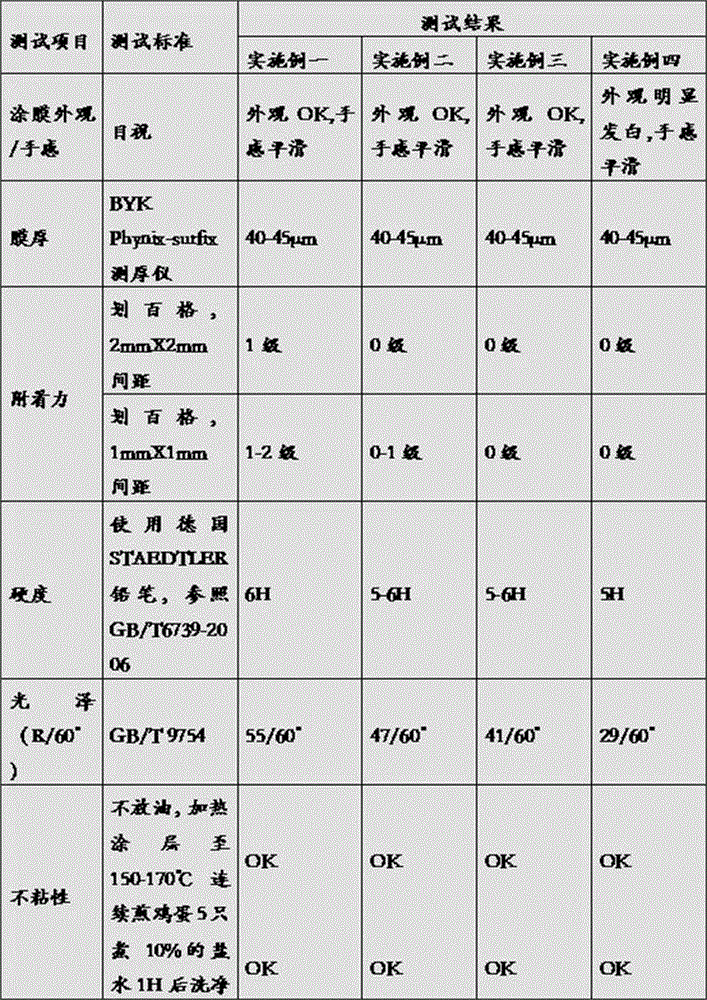

[0035] In Example 1, surface dry at 100°C / 5-10min first, and then cure at 220°C / 20min; in Example 2, 3, and 4, dry at 100°C / 5-10min first, and then cure at 400°C / 10min. Then compare The prope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com