Heat-insulating, waterproof and environment-friendly paint and preparation method thereof

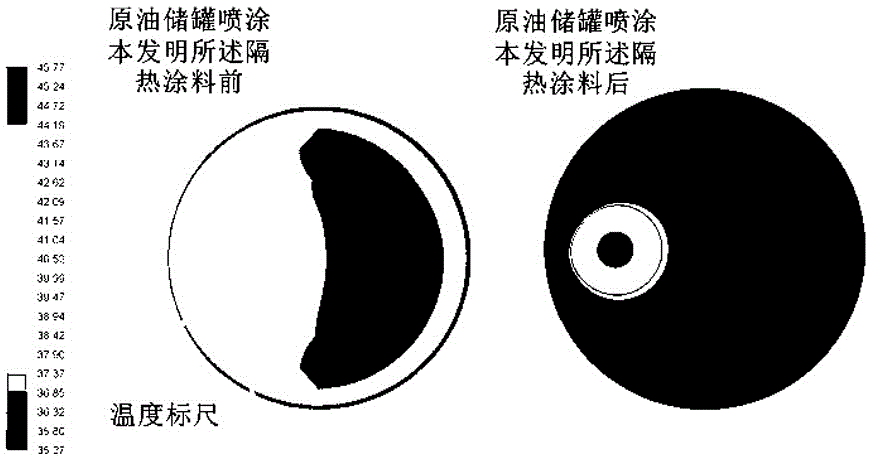

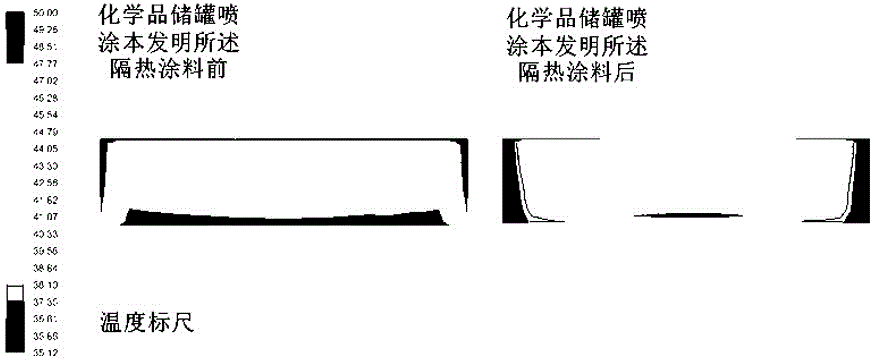

An environmentally friendly coating and pigment technology, applied in anti-corrosion coatings, reflective/signal coatings, coatings, etc., can solve the problems of immature research and development of thermal insulation coatings, containing large harmful gases, human and environmental hazards, and achieve obvious thermal insulation effects. , The effect of strong reactivity and improved architectural aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

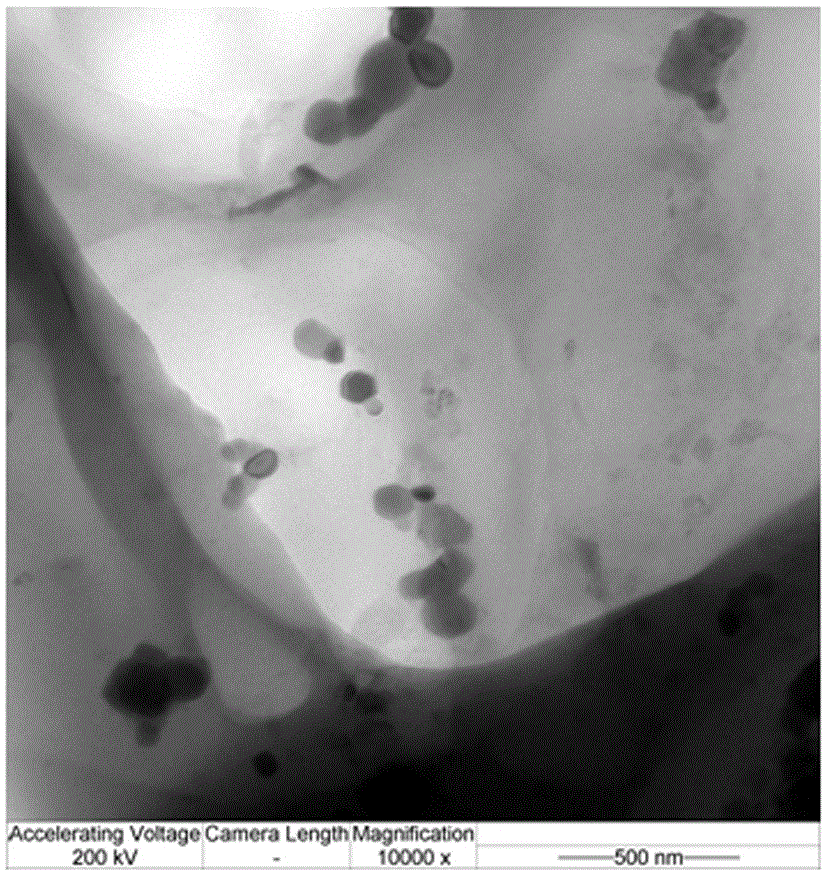

[0032]Add 30g of nano titanium dioxide, 30g of chrome yellow, 30g of fumed white carbon black, 30g of phthalocyanine green and 30g of permanent violet, 50g of calcium carbonate, 50g of talc, 50g of calcined kaolin, 50g of aluminum silicate and 50g of bentonite into 150g of deionized water, Stir for 1 hour at a stirring speed of 1000 rpm to achieve full dispersion of pigments and fillers. Then, 50g of porous ceramic microspheres, 50g of hollow glass microspheres, 50g of nano-paraffin and 260g of acrylic emulsion were added to the mixed solution, and stirred for 1 hour at a stirring speed of 700 rpm. Finally, 40 g of additives were added into the mixed solution, and stirred for 30 minutes at a stirring speed of 600 revolutions per minute to obtain a heat-insulating, waterproof and environmentally friendly coating. In this example, the additives include 10g Lugong P105, 8g Zhonglian B315, 3gDZ01, 15g BYK380N, 4g Lanxess Vulkanox4030; the pigment size is 800 mesh to 6000 mesh; the...

Embodiment 2

[0035] Add 30g of chrome yellow, 30g of fumed white carbon black, 30g of phthalocyanine blue, 30g of permanent violet, 60g of talc, 60g of precipitated barium sulfate, 20g of aluminum silicate and 40g of bentonite into 200g of deionized water, and stir for 1 hour at a stirring speed of 1000 revolutions per minute to achieve full dispersion of pigments and fillers. Then add 40g of hollow glass microspheres, 20g of nano-ATO powder, 15g of nano-titanium dioxide, 25g of nano-paraffin and 340g of acrylic emulsion into the mixed solution, and stir for 1 hour at a stirring speed of 700 rpm. Finally, 60 g of additives were added into the mixed solution, and stirred for 30 minutes at a stirring speed of 600 revolutions per minute; a heat-insulating, waterproof and environmentally friendly coating was obtained. In this example, the additives include 12g Lugong LBCB1, 9gSilcoAF881, 8gDZ01, 15gSilcoFLWK-134, 11g Shengda Chemical SD-505, 5g Lanxess Vulkanox4030; the size of the pigment is ...

Embodiment 3

[0038] Add 30g of chrome yellow, 10g of phthalocyanine blue, 50g of permanent violet, 60g of talc, and 60g of precipitated barium sulfate into 100g of deionized water and stir for 1 hour at a stirring speed of 1000 rpm to fully disperse the pigments and fillers. Then add 30g of hollow glass microspheres, 20g of nano-ATO powder, 8g of nano-titanium dioxide, 2g of nano-paraffin and 150g of acrylic emulsion into the mixed solution, and stir for 1 hour at a stirring speed of 700 rpm. Finally, 10 g of additives were added into the mixed solution, and stirred for 30 minutes at a stirring speed of 600 revolutions per minute; a heat-insulating, waterproof and environmentally friendly coating was obtained. In this example, the additives include 3g Lugong LBCB1, 1gSilcoAF881, 1gDZ01, 2gNordesC15, 2g Shengda Chemical SD-505, 1g Hantai Chemical AR-2; the pigment size is 800 mesh to 6000 mesh; the filler size is 600 mesh to 6000 mesh; the size of porous inorganic materials is 3000 mesh to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com