Preparation method of high-toughness aluminum base nanometer composite material

A technology of nanocomposite materials and composite materials, which is applied in the field of preparation of aluminum-based nanocomposite materials, can solve the problems of reducing the strength and toughness of composite materials, coarse grains, and difficult industrial applications, so as to enhance strength and toughness, improve severe agglomeration, and fine grains. The effect of microstructure grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of High Strength and Toughness Aluminum Matrix Nanocomposite ZrB 2 / 6082Al; specific implementation methods:

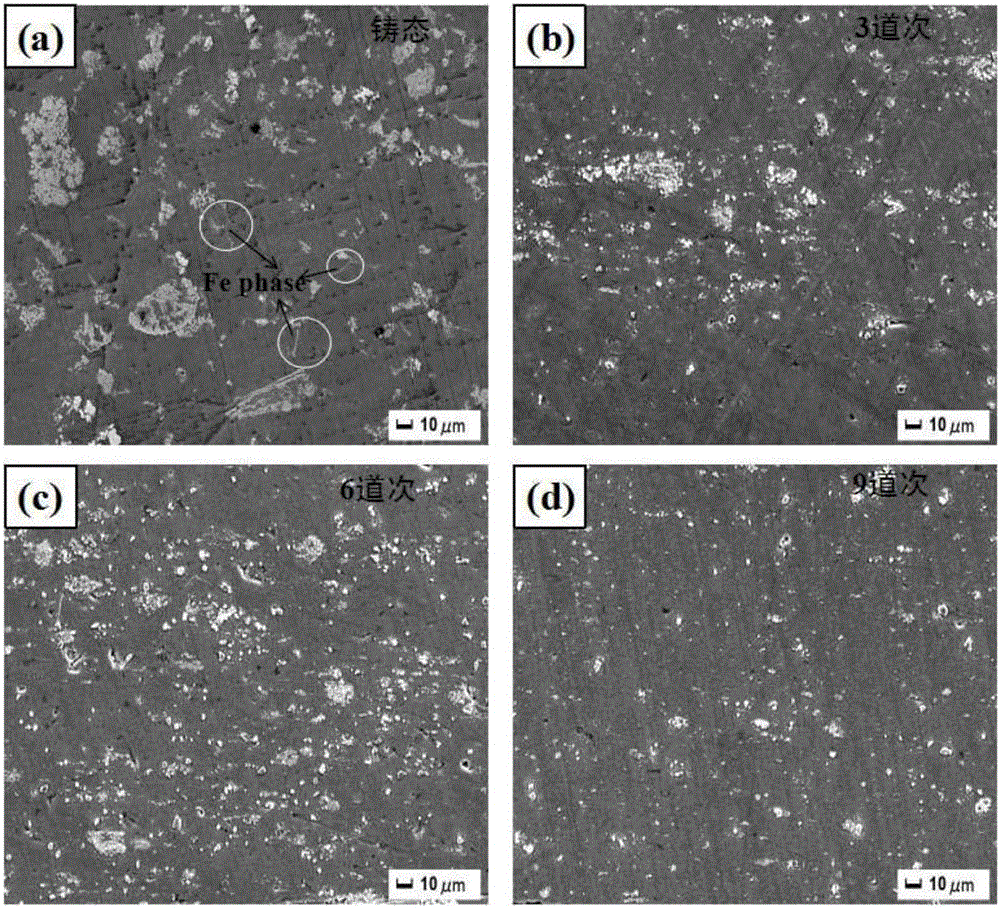

[0030] (1) with K 2 ZrF 6 and KBF 4 As a reactant, according to generate 3wt.% nanometer ZrB 2 The particles are chemically proportioned, using the melt direct reaction method, at 870 ° C, accompanied by a spiral magnetic field, reacting in the molten 6082Al melt for 30 minutes, refining and removing slag, standing still, and in situ synthesis of nano-ZrB 2 / 6082Al, Nano ZrB 2 The size is 30-80nm, and the obtained cast nano-ZrB 2 / 6082Al was subjected to solution treatment at 560°C×3h, aging treatment at 175°C×8h, and then air-cooled.

[0031](2) In situ nanoparticles reinforced aluminum matrix composite ZrB 2 / 6082Al cut into regular shape, prepared into 120×40×1mm ZrB 2 / 6082Al plate.

[0032] (3) ZrB after cleavage 2 / 6082Al plate surface is degreased, pickled in a mixture of alcohol and acetone with a volume ratio of 1:2, and then mech...

Embodiment 2

[0044] Preparation of High Strength and Toughness Aluminum Matrix Nanocomposite ZrB 2 / 6082Al; specific implementation methods:

[0045] with K 2 ZrF 6 and Na 2 B 4 o 7 As a reactant, according to generate 5wt.% nanometer ZrB 2 The particles are chemically proportioned, using the melt direct reaction method, at 850 ° C, accompanied by high-energy ultrasound, reacting in the molten 6082Al melt for 30 minutes, refining and removing slag, standing still, and in-situ synthesis of nano-ZrB 2 / 6082Al, nano-sized ZrB 2 40-100nm, cumulative rolling pass is 5 passes, rolling process parameters are: rolling temperature is 250°C, deformation rate is 0.2s -1 , the rest of the steps are the same as in Example 1, and finally obtain the high-strength and tough aluminum-based nanocomposite ZrB 2 / 6082Al.

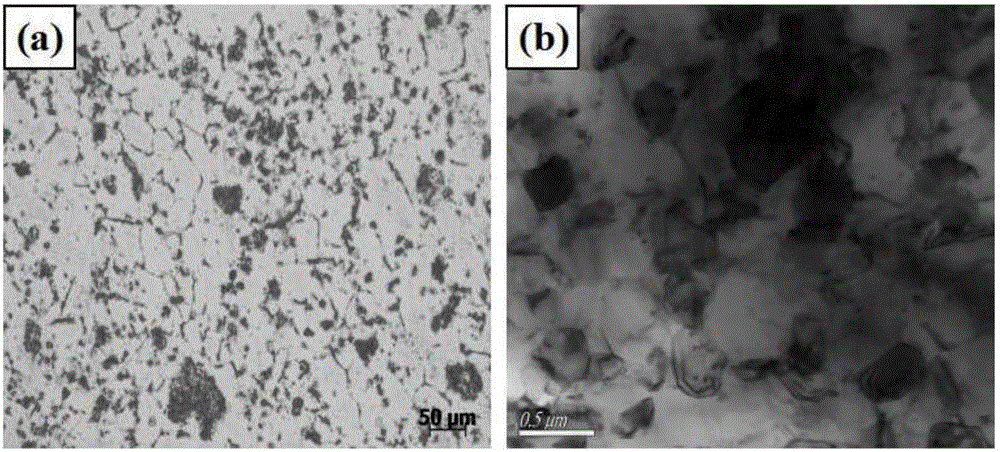

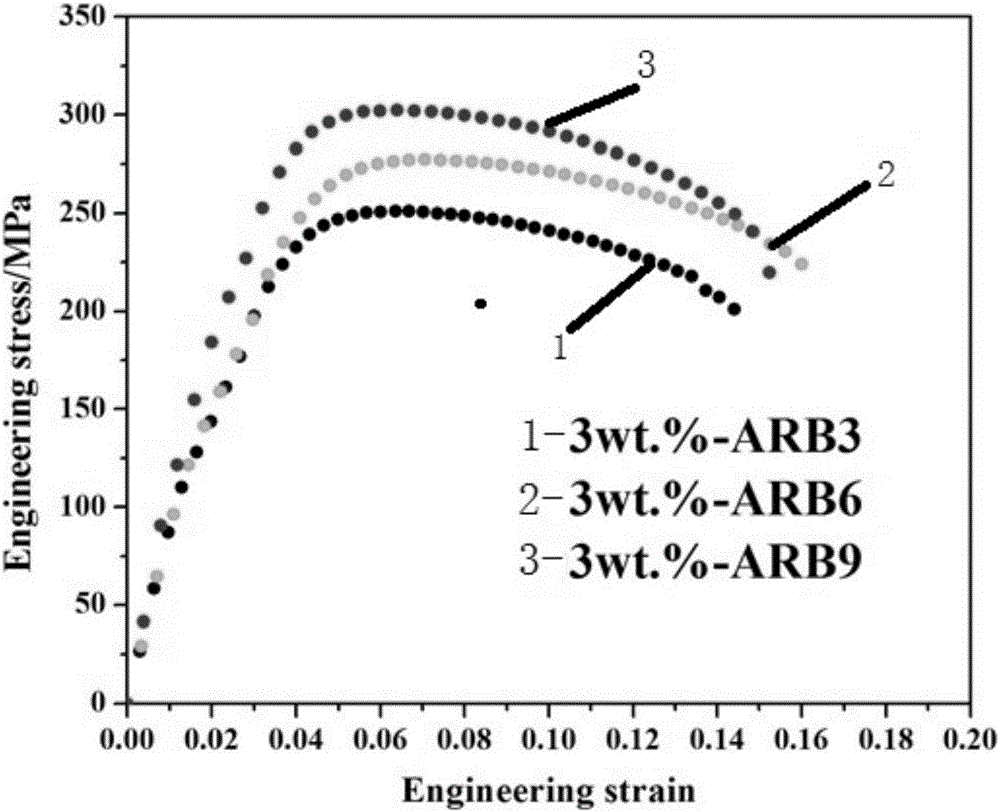

[0046] The obtained composite material was sampled for structural analysis, and the results showed that: nano-ZrB 2 The particle dispersion is also evenly distributed, and the gra...

Embodiment 3

[0049] Preparation of high strength and toughness aluminum matrix nanocomposites (ZrB 2 +TiB 2 ) / 6063Al; specific implementation methods:

[0050] with K 2 ZrF 6 , K 2 TiF 6 and KBF 4 As a reactant, according to generate 3wt.%ZrB 2 Granules, 1wt.% TiB 2 The particles were stoichiometrically proportioned, using the melt direct reaction method, at 900 ° C, accompanied by spiral magnetic field stirring, mechanical stirring, reacting in the molten 6063Al melt for 30 minutes, refining and removing slag, standing still, in situ synthesis of cast (ZrB 2 +TiB 2 ) / 6063Al composite material, ZrB 2 Size 40-100nm, TiB 2 The size is 380-420nm, and the obtained as-cast composite material is subjected to solution treatment at 540°C×3h, aging treatment at 190°C×9h, and then air-cooled. (ZrB 2 +TiB 2 ) / 6063Al rolling process parameters are: rolling temperature is 275°C, rolling speed is 0.15s -1 , the number of overlapping rolling is 7 passes. All the other steps are the same as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com