Lightweight long-staple cotton, hollow special-shaped polyester blended yarn jacquard warm knitted fabric

A technology of knitted fabrics and long-staple cotton, applied in the field of thermal knitted fabrics, can solve the problems of low breaking strength, immaturity, poor dyeing performance, etc., and achieve the effect of improving the overall style, improving the poor hand feeling and high skin-friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

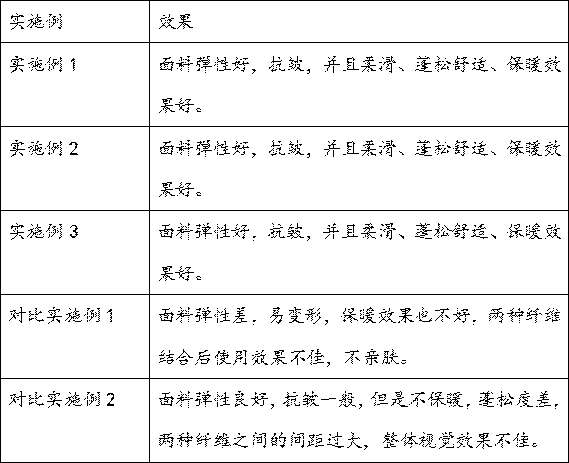

Embodiment 1

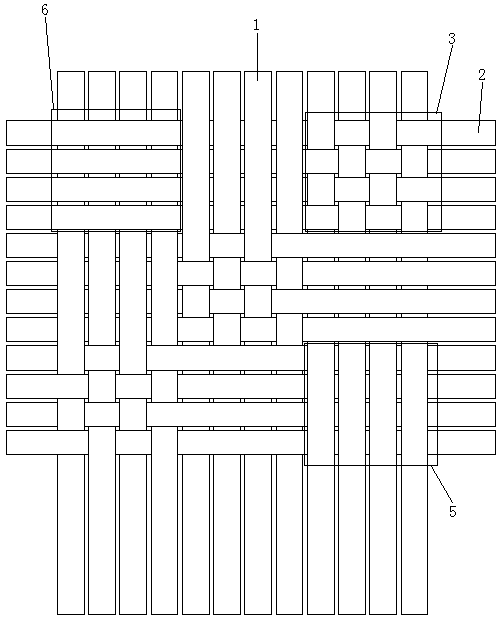

[0039] Such as figure 1 As shown, the lightweight long-staple cotton and hollow special-shaped polyester blended yarn jacquard warm knitted fabric is made of long-staple cotton and hollow special-shaped polyester as raw materials. The knitted fabric is made of silicone anti-wrinkle finishing agent and polyether modified amino Finishing technology of silicone oil softener;

[0040] The technical conditions for finishing are: 200 parts by weight of polyether modified amino silicone oil softener, 250 parts by weight of silicone anti-wrinkle finishing agent, 1 part by weight of soap oil, 2 parts by weight of malic acid, 100 parts by weight of water, is 75%, and the shrinking machine speed is 7m / min;

[0041] The paste of polyether modified amino silicone oil softener is: 300 parts by weight of amino silicone oil, 3 parts by weight of trimethoxymethylsilane, 30 parts by weight of polyoxyethylene tridecyl ether, and an appropriate amount of water to form a 5% emulsion;

[0042] Si...

Embodiment 2

[0060] Embodiment 2 is the same as Embodiment 1, and the difference is:

[0061] The technical conditions for finishing are: 300 parts by weight of polyether modified amino silicone oil softener, 400 parts by weight of silicone anti-wrinkle finishing agent, 3 parts by weight of soap oil, 5 parts by weight of malic acid, 300 parts by weight of water, is 85%, and the shrinking machine speed is 11m / min;

[0062] The paste of polyether modified amino silicone oil softener is: 200 parts by weight of amino silicone oil, 1 part by weight of trimethoxymethylsilane, 25 parts by weight of polyoxyethylene tridecyl ether, and an appropriate amount of water to form a 6% emulsion;

[0063] Silicone anti-wrinkle finishing agent includes the following components and weight ratio:

[0064] 6 parts of polysiloxane, 3 parts of hydroxyl-terminated polybutadiene, 6 parts of trimethylolpropane, 10 parts of aminopropyl trimethoxysilane, 8 parts of dimethylol butyric acid, 15 parts of isophorone dii...

Embodiment 3

[0073] Embodiment 3 is the same as Embodiment 1, and the difference is:

[0074] The technical conditions for finishing are: 250 parts by weight of polyether modified amino silicone oil softener, 280 parts by weight of silicone anti-wrinkle finishing agent, 1.5 parts by weight of soap oil, 3 parts by weight of malic acid, 240 parts by weight of water, is 82%, and the shrinking machine speed is 10m / min;

[0075]The slurry of polyether modified amino silicone oil softener is: 260 parts by weight of amino silicone oil, 1.5 parts by weight of trimethoxymethylsilane, 27 parts by weight of polyoxyethylene tridecyl ether, and an appropriate amount of water to form a 5.8% emulsion;

[0076] Silicone anti-wrinkle finishing agent includes the following components and weight ratio:

[0077] 7 parts of polysiloxane, 4 parts of hydroxyl-terminated polybutadiene, 7 parts of trimethylolpropane, 12 parts of aminopropyl trimethoxysilane, 9 parts of dimethylol butyric acid, 17 parts of isophor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com