High temperature TFT (Thin Film Transistor) composite flexible substrate, preparation method of the high temperature TFT composite flexible substrate and flexible display device preparation method

A composite flexible and flexible substrate technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the requirements that do not meet the development requirements of high-resolution flexible displays, affect the accuracy and uniformity of TFT devices, and thermal expansion coefficient Large and other problems, achieve the effect of strengthening mechanical stability, suppressing thermal expansion, and reducing thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

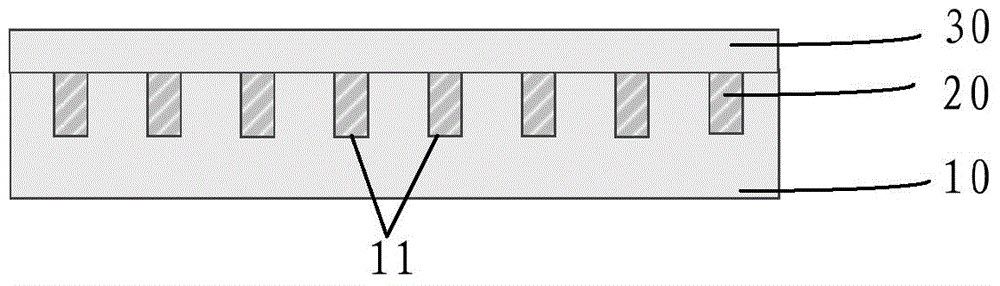

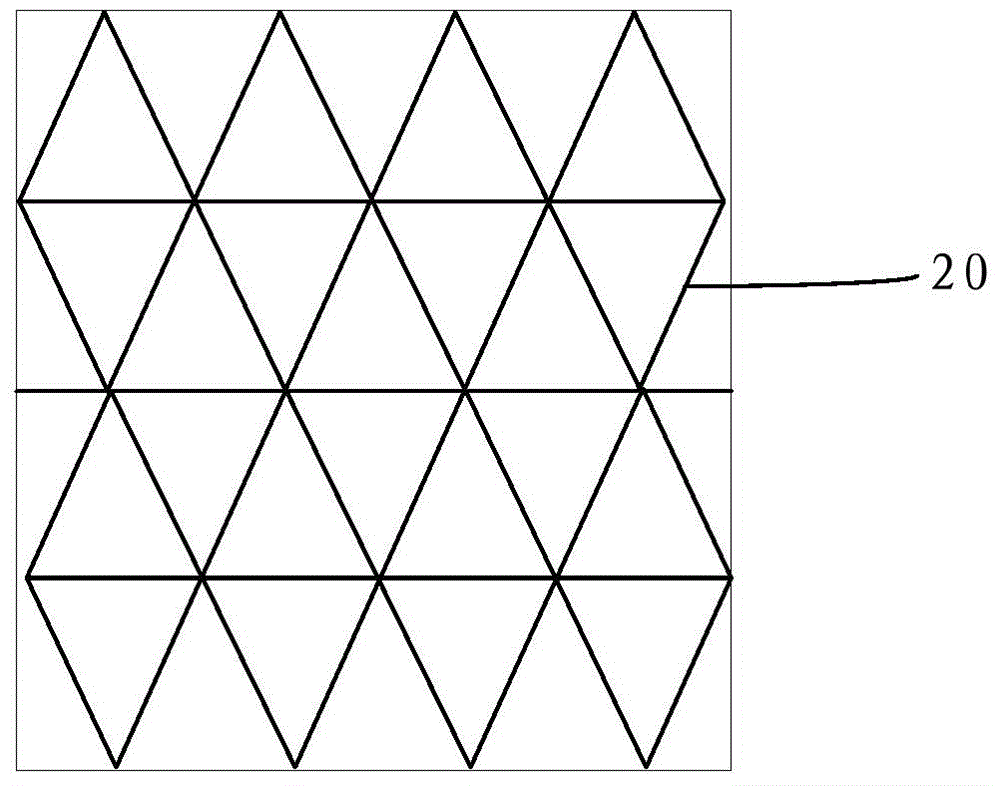

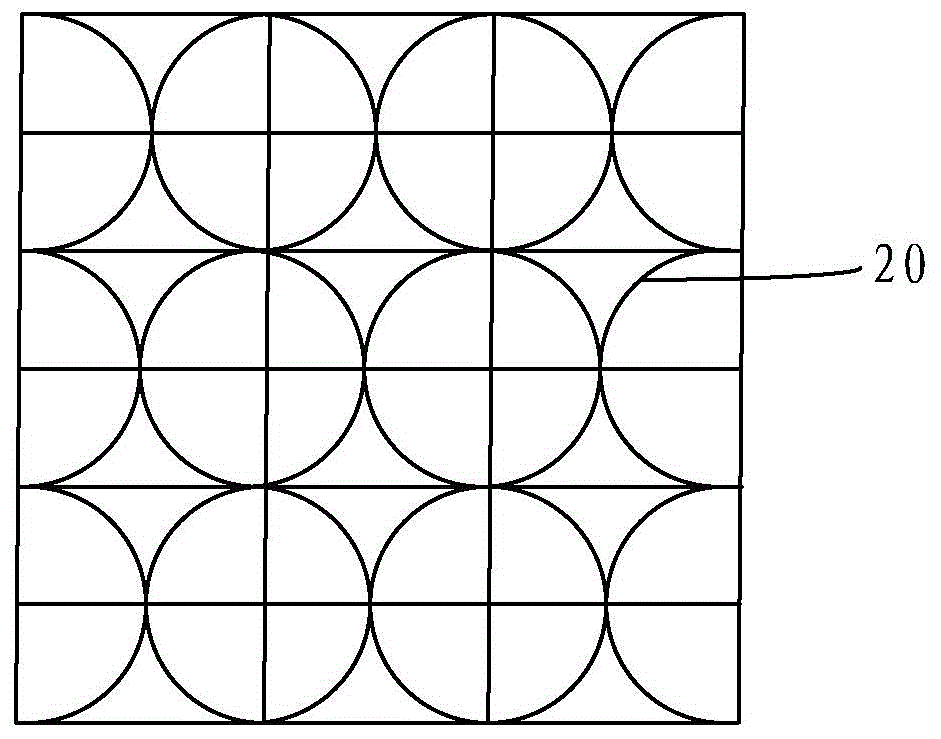

[0056] In the preparation process of the present invention, nanoimprinting technology is used to form a skeleton model on the surface of the flexible substrate layer 10, and then filled with materials to form a reinforced skeleton 20. Embedding the skeleton into the flexible substrate layer 10, when the flexible substrate layer 10 thermally expands, it can restrict and slow down the molecular flow of its expansion, and at the same time, under the internal support of the skeleton, the toughness and elasticity of the flexible material itself can be further strengthened Modulus and other mechanical properties; and the nanoimprinting method has the least impact on the flexible substrate layer 10 as a flexible display substrate.

[0057] Among them, in this step S10, the flexible substrate layer 10 is obtained as the substrate to be produced, which can be directly used in the present invention by using an existing independent flexible substrate that can meet the requirements of the ...

Embodiment 1

[0088] In this embodiment 1, a phthalic anhydride-type PI resin material is used to realize the preparation of a composite flexible substrate, and a high-brightness glass plate is used as a hard substrate as an example.

[0089] S11, selecting a high-brightness glass plate as the hard substrate, and ultrasonically cleaning the hard substrate, and then performing plasma treatment on the surface of the glass plate with nitrogen gas after cleaning, for standby;

[0090] S12, pour the PI resin solution into the cavity of the scraping knife, and slowly and evenly coat the PI resin solution on the surface of the high-gloss glass plate to form an intermediary layer; then use the method of spin coating (Spincoating) to carry out Rotate to make the intermediary layer formed by doctor blade coating to a uniform thickness of 2 μm to 5 μm, then place it in a radiation oven filled with nitrogen atmosphere, and heat it with infrared radiation until the intermediary layer of PI resin is cross...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com