A method for selective directional deposition of organic thin films

A technology of organic thin film and deposition method, which is applied in the field of selective directional deposition of organic thin film, can solve the problems of complex equipment, high cost, waste of materials, etc., and achieve the effect of precise and controllable deposition position, easy patterning, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The selective directional deposition method of the organic film of the AMOLED of the present embodiment comprises the following steps:

[0035] (1) The pixel electrode on the AMOLED substrate is used as the working electrode, and the thin film transistor drive circuit on the AMOLED substrate is connected in series to the electrolytic cell circuit of electrochemical deposition:

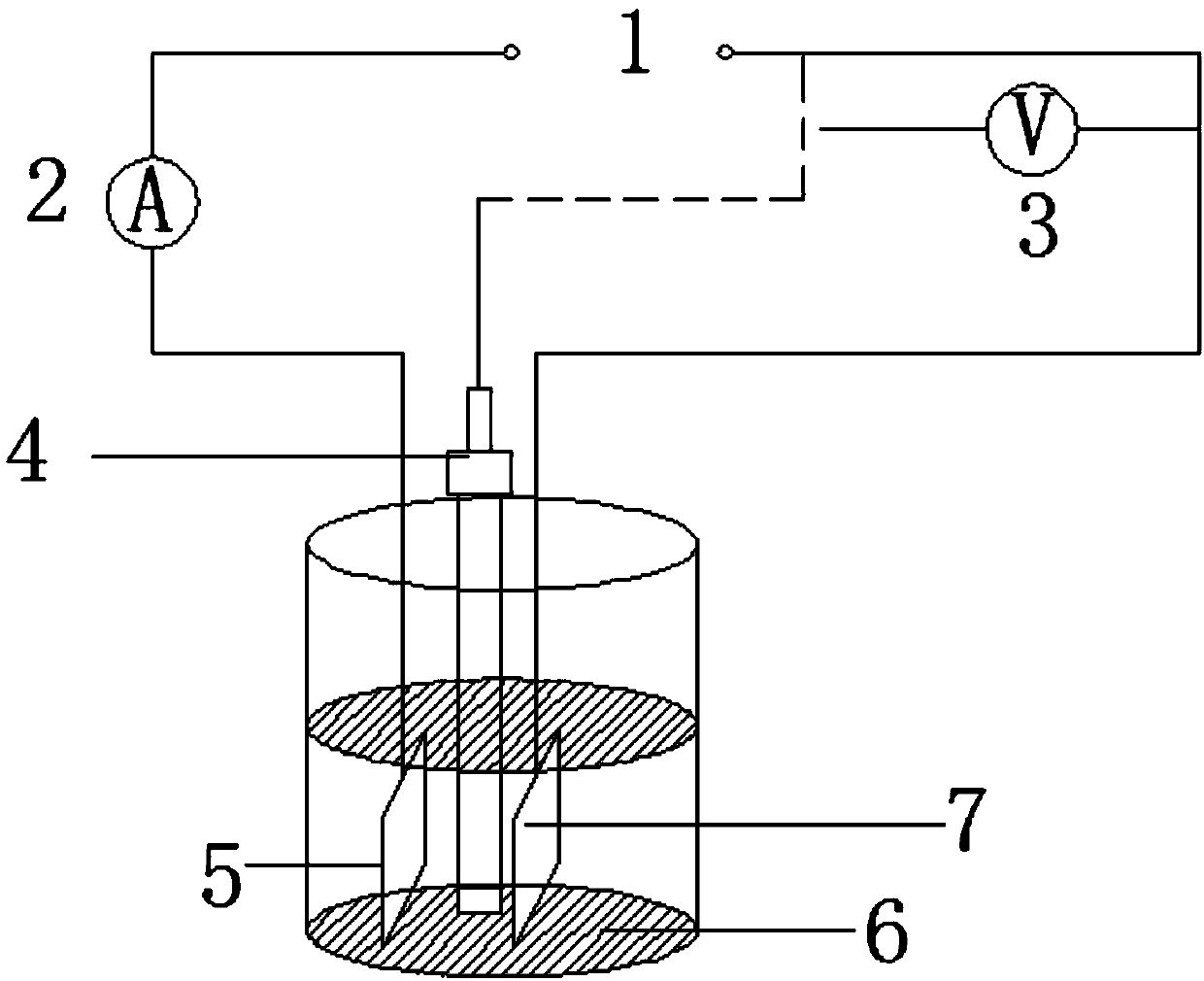

[0036] The electrolytic cell circuit for realizing the selective directional deposition method of the organic film of the AMOLED of the present embodiment is as follows: figure 1 As shown, the electrolytic cell circuit includes an electrochemical workstation 1, an ammeter 2, a voltmeter 3, an auxiliary electrode 5, a reference electrode 4, an electrolyte 6, and an AMOLED substrate 7; the auxiliary electrode 5 and the AMOLED substrate 7 are placed in the electrolyte 6 Middle; the auxiliary electrode 5 is connected to the electrochemical workstation 1; the reference electrode 4 is placed between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com