Preparation method of raw potato full flour

A raw potato powder and potato technology, applied in the direction of food science, etc., can solve the problems affecting the dehydration and drying rate of potatoes, the odor of raw potato powder, and prolonged drying time, and achieve huge economic and environmental benefits, low gelatinization degree, The effect of accelerating the drying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

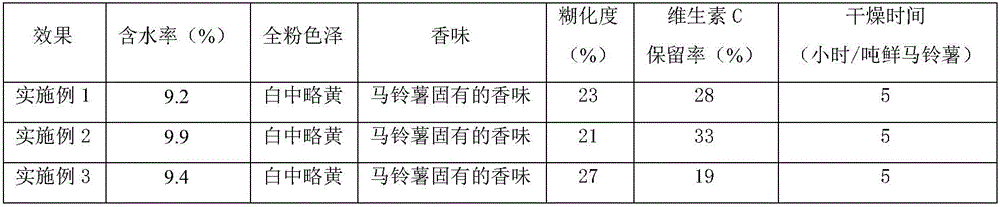

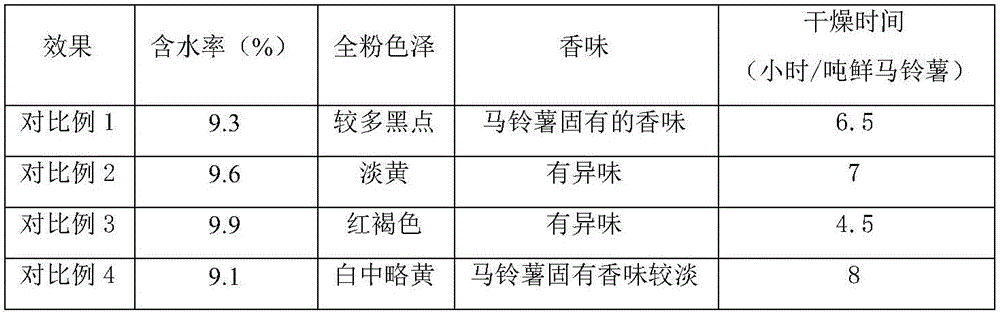

Examples

Embodiment 1

[0023] Step 1 preprocessing:

[0024] Select potato raw materials with smooth surface, less impurities, no mildew, and shallow bud eyes. The mass fraction of solid matter is W g 27%, after removing the epidermis, dice, the size of the dices is a square with a side length of 5mm;

[0025] Solid mass fraction W g The calculation formula is:

[0026] Wherein, M is the mass of 100 diced potatoes selected before drying, in grams; m g is the mass of 100 selected diced potatoes after complete drying, in grams.

[0027] Step 2 Drying: Put the diced potatoes into a downstream hot air dryer for segmental variable temperature drying with a wind speed of 6m / s and an initial drying temperature of 80°C. When the water content in the diced potatoes is W s When the temperature is 40%, the transformation temperature is 60°C, when the water content in the diced potato is W s When it is 20%, the drying temperature is changed to 40°C, and it is dried to a moisture content of W s ≤10%;

...

Embodiment 2

[0035] Step 1 preprocessing:

[0036] Select potato raw materials with smooth surface, less impurities, no mildew, and shallow bud eyes. The mass fraction of solid matter is W g 27%, after removing the epidermis, dice, the size of the dices is a square with a side length of 10mm;

[0037] Solid mass fraction W g The calculation formula is:

[0038] Wherein, M is the mass of 100 diced potatoes selected before drying, in grams; m g is the mass of 100 selected diced potatoes after complete drying, in grams.

[0039] Step 2 Drying: Put the diced potatoes into a co-flow hot air dryer for segmental variable temperature drying with a wind speed of 7m / s and an initial drying temperature of 90°C. When the water content in the diced potatoes is W s When the temperature is 40%, the transition temperature is 70°C, when the water content in the diced potato is W s When it is 20%, the drying temperature is changed to 50°C, and it is dried to a moisture content of W s ≤10%;

[0040]...

Embodiment 3

[0044] Step 1 preprocessing:

[0045]Select potato raw materials with smooth surface, less impurities, no mildew, and shallow bud eyes. The mass fraction of solid matter is W g 27%, after removing the epidermis, dice, the size of the dices is a square with a side length of 15mm;

[0046] Solid mass fraction W g The calculation formula is:

[0047] Wherein, M is the mass of 100 diced potatoes selected before drying, in grams; m g is the mass of 100 selected diced potatoes after complete drying, in grams.

[0048] Step 2 Drying: Put the diced potatoes into a co-flow hot air dryer for segmental variable temperature drying with a wind speed of 8m / s and an initial drying temperature of 95°C. When the water content in the diced potatoes is W s When the temperature is 40%, the transition temperature is 80°C, when the water content in the diced potato is W s When it is 20%, the drying temperature is changed to 60°C, and it is dried to a moisture content of W s ≤10%;

[0049] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com