A kind of preparation method of controllable water-absorbing silicon dioxide microsphere

A technology of silica and microspheres, applied in the direction of silica, silica, etc., can solve the problems of difficult control of water absorption, reduction of purification stability and repeatability, and difficulty in repeating purification results, etc., to achieve a simple and easy-to-control process , excellent mechanical stability, the effect of narrow pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

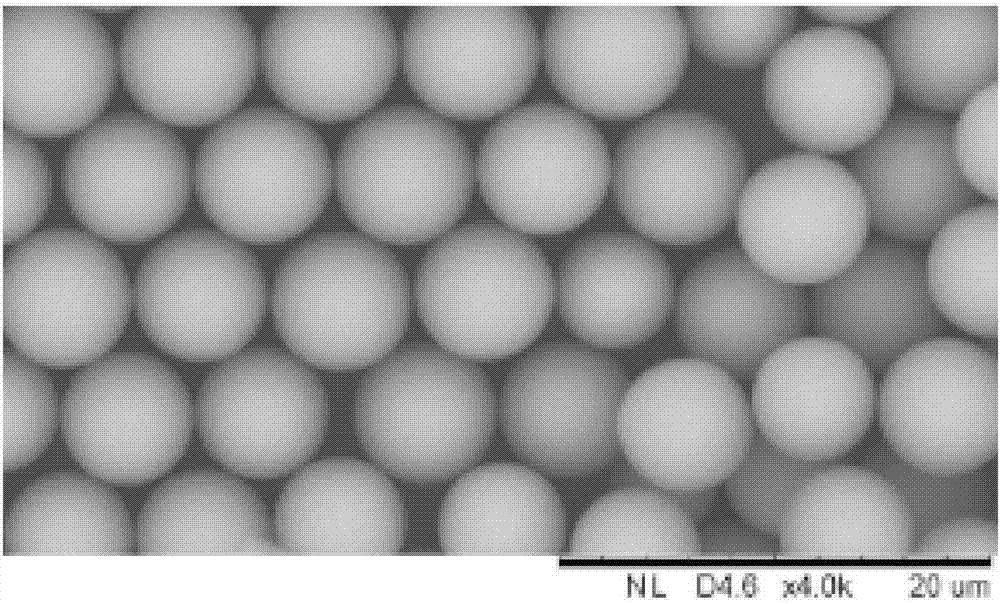

[0043] Preparation of controllable water-absorbing silica microspheres

[0044] The preparation steps are as follows

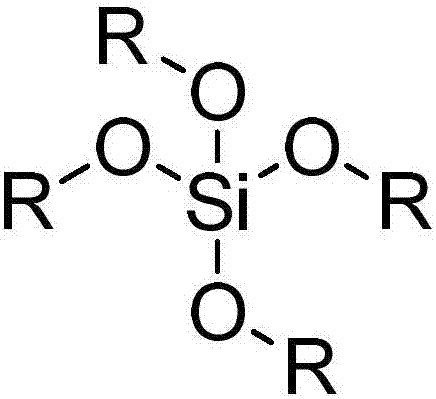

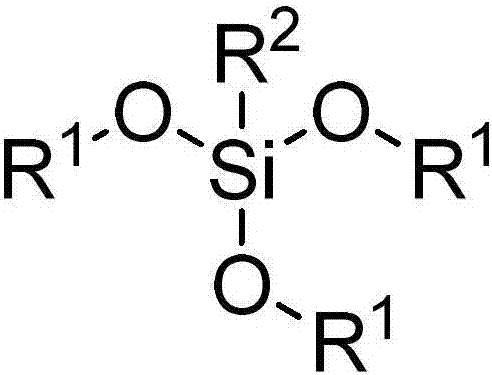

[0045] 1) Add 281.25g of ethyl orthosilicate and 26.75g of triethoxymethylsilane into 217.68g of absolute ethanol, stir magnetically until completely dispersed and form a homogeneous phase.

[0046] 2) Add 52.84g of 0.1M HCl dropwise to the solution obtained in step 1) under magnetic stirring, raise the temperature to 70°C, and keep at this temperature for 20h to partially hydrolyze the silicon source to form a silica sol.

[0047] 3), the sol obtained in step 2) removes the solvent by rotary evaporation.

[0048] 4) Take 20 g of the sol obtained in step 3), add 1 g of toluene, and stir magnetically to make it homogeneous.

[0049] 5), step 4) the oil phase prepared is dispersed in 100g H 2 O and 2g of surfactant (HBL=14pan80:Tween80=1:10) in the aqueous phase. Emulsify for 3h under magnetic stirring at 500r / min.

[0050] 6) Add 15mL of ammonia water (15%...

Embodiment 2

[0054] Preparation of controllable water-absorbing silica microspheres

[0055] The preparation steps are as follows

[0056] 1) Add 156.25g of methyl orthosilicate and 133.72g of triethoxymethylsilane into 217.68g of absolute ethanol, stir magnetically until completely dispersed and form a homogeneous phase.

[0057] 2) Add 52.84g of 0.1M HCl dropwise to the solution obtained in step 1) under magnetic stirring, raise the temperature to 70°C, and keep at this temperature for 20h to partially hydrolyze the silicon source to form a silica sol.

[0058] 3), the sol obtained in step 2) removes the solvent by rotary evaporation.

[0059] 4) Take 20 g of the sol obtained in step 3), add 1 g of toluene, and stir magnetically to make it homogeneous.

[0060] 5), step 4) the oil phase prepared is dispersed in 100g H 2 O and 2g of surfactant (HBL=14pan80:Tween80=1:10) in the aqueous phase. Emulsify for 3h under magnetic stirring at 500r / min.

[0061] 6) Add 15mL of ammonia water (1...

Embodiment 3

[0065] Preparation of controllable water-absorbing silica microspheres

[0066] The preparation steps are as follows

[0067] 1) Add 31.25g of ethyl orthosilicate and 240.70g of triethoxymethylsilane into 217.68g of absolute ethanol, stir magnetically until completely dispersed and form a homogeneous phase.

[0068] 2) Add 52.84g of 0.1M HCl dropwise to the solution obtained in step 1) under magnetic stirring, raise the temperature to 70°C, and keep at this temperature for 20h to partially hydrolyze the silicon source to form a silica sol.

[0069] 3), the sol obtained in step 2) removes the solvent by rotary evaporation.

[0070] 4) Take 20 g of the sol obtained in step 3), add 1 g of toluene, and stir magnetically to make it homogeneous.

[0071] 5), step 4) the oil phase prepared is dispersed in 100g H 2 O and 2g of surfactant (HBL=14pan80:Tween80=1:10) in the aqueous phase. Emulsify for 3h under magnetic stirring at 500r / min.

[0072] 6) Add 15mL of ammonia water (15%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com