Asphalt mixture for heavy traffic roads and preparation method thereof

An asphalt mixture, heavy traffic technology, applied in building insulation materials, building components, buildings, etc., can solve the problems of anti-wear and anti-rutting effects, etc., and achieve great social significance and industry value, little change in asphalt, Excellent anti-rutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

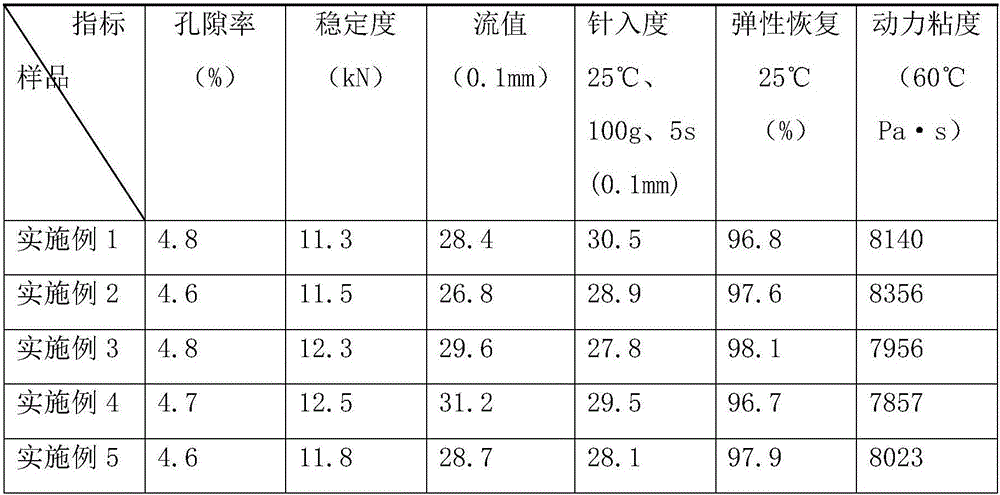

Examples

Embodiment 1

[0042]An asphalt mixture for heavy traffic roads, comprising the following raw materials in parts by weight: 50 parts of asphalt, 200 parts of mineral powder, 50 parts of aggregate, 5 parts of inorganic fiber, 10 parts of ultra-high molecular weight polyethylene, and 20 parts of rubber powder , 10 parts of diatomaceous earth.

[0043] Among them, the asphalt technical indicators used are as follows:

[0044] (1) The penetration of a load of 100 grams sinking into a grease sample at 25°C within 5 seconds is 2-4 mm; the penetration index is ≥ -0.4;

[0045] (2) Kinematic viscosity at 135°C≤2.8Pa·s; dynamic viscosity at 60°C≥4500Pa·s;

[0046] (3) Viscosity and toughness≥5N·m; toughness≥2.5N·m; flash point≥230℃; solubility≥99%; softening point≥60℃;

[0047] (4) During the storage stability segregation test, the softening point difference after storage for 48 hours is ≤2.5°C;

[0048] (5) Elastic recovery at 25°C ≥ 70%;

[0049] (6) Dynamic shear at 35°C ≥ 1000kPa, dynamic she...

Embodiment 2

[0060] An asphalt mixture for heavy traffic roads, comprising the following raw materials in parts by weight: 60 parts of asphalt, 230 parts of mineral powder, 60 parts of aggregate, 6 parts of inorganic fiber, 12 parts of ultra-high molecular weight polyethylene, and 25 parts of rubber powder , 12 parts of diatomaceous earth.

[0061] Wherein, the technical index of described asphalt is as follows:

[0062] (1) The penetration of a load of 100 grams sinking into a grease sample at 25°C within 5 seconds is 2-4 mm; the penetration index is ≥ -0.4;

[0063] (2) Kinematic viscosity at 135°C≤2.8Pa·s; dynamic viscosity at 60°C≥4500Pa·s;

[0064] (3) Viscosity and toughness≥5N·m; toughness≥2.5N·m; flash point≥230℃; solubility≥99%; softening point≥60℃;

[0065] (4) During the storage stability segregation test, the softening point difference after storage for 48 hours is ≤2.5°C;

[0066] (5) Elastic recovery at 25°C ≥ 70%;

[0067] (6) Dynamic shear at 35°C ≥ 1000kPa, dynamic she...

Embodiment 3

[0078] An asphalt mixture for heavy traffic roads, comprising the following raw materials in parts by weight: 80 parts of asphalt, 250 parts of mineral powder, 80 parts of aggregate, 8 parts of inorganic fiber, 15 parts of ultra-high molecular weight polyethylene, and 30 parts of rubber powder , 15 parts of diatomaceous earth and 3 parts of phosphorus-containing organic matter.

[0079] Wherein, the technical index of described asphalt is as follows:

[0080] (1) The penetration of a load of 100 grams sinking into a grease sample at 25°C within 5 seconds is 2-4 mm; the penetration index is ≥ -0.4;

[0081] (2) Kinematic viscosity at 135°C≤2.8Pa·s; dynamic viscosity at 60°C≥4500Pa·s;

[0082] (3) Viscosity and toughness≥5N·m; toughness≥2.5N·m; flash point≥230℃; solubility≥99%; softening point≥60℃;

[0083] (4) During the storage stability segregation test, the softening point difference after storage for 48 hours is ≤2.5°C;

[0084] (5) Elastic recovery at 25°C ≥ 70%;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com