Aerated concrete block surface mortar and production method thereof

A technology for air-entrained concrete and plastering mortar, which is applied to other household appliances, applications, household appliances, etc., can solve problems such as excessive blisters and scratches, inability to meet mechanized construction, and difficulty in rubbing and plastering natural sand, etc. Outstanding crack resistance and waterproof performance, saving manpower and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

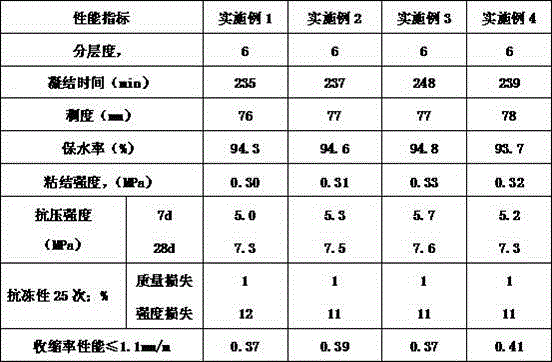

Examples

Embodiment 1

[0022] 60 parts of aggregate, 10 parts of 42.5 Portland cement, 10 parts of fly ash, 0.1 part of water reducer, 2 parts of redispersible latex powder, 0.1 part of cellulose ether, 0.1 part of wood fiber, and 0.02 part of air-entraining agent After weighing 0.5 parts of polypropylene fiber, first put fly ash, water reducer, redispersible latex powder, cellulose ether, wood fiber, air-entraining agent and polypropylene fiber into the mixer for stirring and mixing, and then put 42.5 Portland cement is added to the mixer and mixed, and finally the aggregate is added to the mixer and mixed, and then put into the finished product packaging tank, inspected and packaged, and the product is obtained.

Embodiment 2

[0024] 70 parts of aggregate, 14 parts of 42.5 Portland cement, 15 parts of fly ash, 0.2 parts of water reducer, 2.5 parts of redispersible latex powder, 0.2 parts of cellulose ether, 0.2 parts of wood fiber, and 0.03 parts of air-entraining agent After weighing 1 portion of polypropylene fiber, first put fly ash, water reducer, redispersible latex powder, cellulose ether, wood fiber, air-entraining agent and polypropylene fiber into the mixer for stirring and mixing, and then put 42.5 Portland cement is added to the mixer and mixed, and finally the aggregate is added to the mixer and mixed, and then put into the finished product packaging tank, inspected and packaged, and the product is obtained.

Embodiment 3

[0026] 75 parts of aggregate, 18 parts of 42.5 Portland cement, 18 parts of fly ash, 0.25 parts of water reducer, 3 parts of redispersible latex powder, 0.4 parts of cellulose ether, 0.4 parts of wood fiber, and 0.04 parts of air-entraining agent After weighing 2 parts with polypropylene fiber, first put fly ash, water reducer, redispersible latex powder, cellulose ether, wood fiber, air-entraining agent and polypropylene fiber into the mixer for stirring and mixing, and then put 42.5 Portland cement is added to the mixer and mixed, and finally the aggregate is added to the mixer and mixed, and then put into the finished product packaging tank, inspected and packaged, and the product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com