Bio-based polyol and preparation method thereof

A bio-based polyol and product technology, applied in the field of chemical materials, can solve problems such as low hydroxyl value, and achieve the effects of high hydroxyl value, uniform distribution, and improved reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

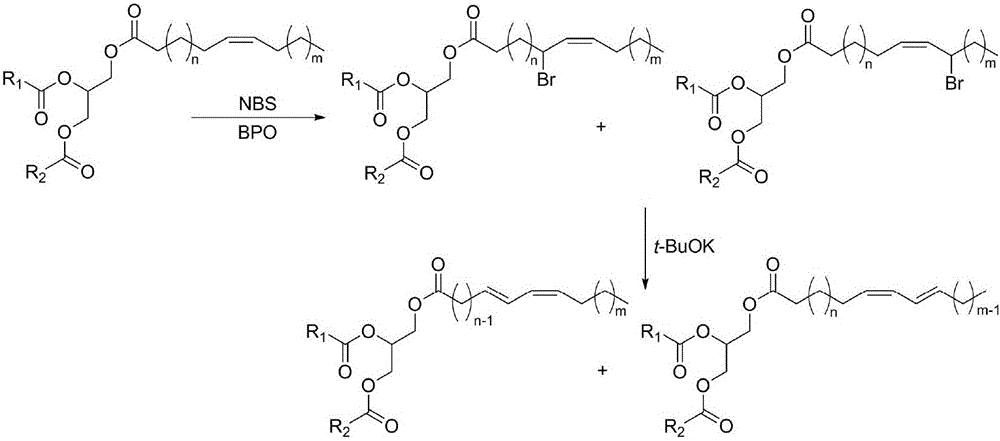

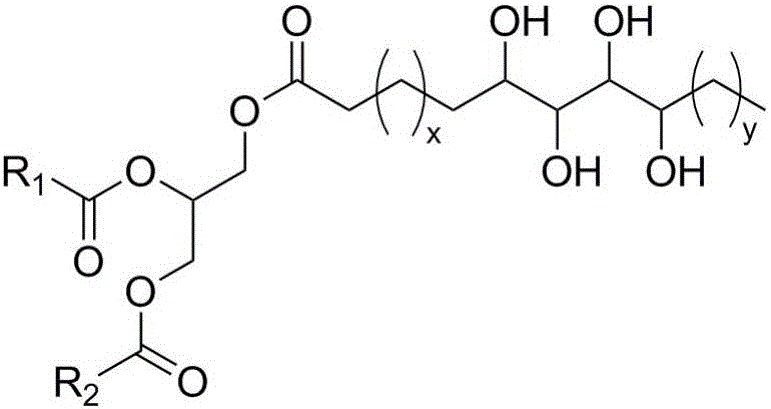

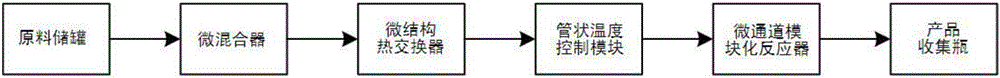

[0036] Dissolve 100g of palm oil in 102mL of anhydrous tetrahydrofuran, add 37.8g of N-bromosuccinimide, and then add 0.94g of catalyst benzoyl peroxide, place the reaction bottle in an oil bath at 35°C and stir for 8h, then Cool to room temperature, filter to remove insoluble matter, concentrate, add ethyl acetate, wash with water, dry over anhydrous sodium sulfate, filter, and concentrate to obtain the brominated product; under nitrogen protection, dissolve the brominated product in 111 mL of anhydrous tetrahydrofuran, Add anhydrous tetrahydrofuran solution of potassium tert-butoxide (43.4g potassium tert-butoxide dissolved in 157mL anhydrous tetrahydrofuran), then react at room temperature for 5h, add water to extract the resulting mixed system twice, then add ethyl acetate to extract twice , combined organic layers, washed with water, dried over anhydrous sodium sulfate, filtered, and concentrated to obtain the unsaturated vegetable oil with increased double bonds; after mi...

Embodiment 2

[0039] Dissolve 100g of coconut oil in 93mL of anhydrous tetrahydrofuran, add 6.7g of N-bromosuccinimide, and then add 0.17g of catalyst benzoyl peroxide, place the reaction bottle in a 40°C oil bath and stir for 9h, then Cool to room temperature, filter to remove insoluble matter, concentrate, add ethyl acetate, wash with water, dry over anhydrous sodium sulfate, filter, and concentrate to obtain the brominated product; under nitrogen protection, dissolve the brominated product in 102 mL of anhydrous tetrahydrofuran, Add anhydrous tetrahydrofuran solution of potassium tert-butoxide (7.7g potassium tert-butoxide dissolved in 30mL anhydrous tetrahydrofuran), then react at room temperature for 6h, add water to extract the resulting mixed system twice, then add ethyl acetate to extract twice , combined organic layers, washed with water, dried over anhydrous sodium sulfate, filtered, and concentrated to obtain the unsaturated vegetable oil with increased double bonds; after mixing ...

Embodiment 3

[0042] Dissolve 100g of camellia oil in 111mL of anhydrous tetrahydrofuran, add 65.4g of N-bromosuccinimide, and then add 1.62g of catalyst benzoyl peroxide, place the reaction bottle in a 45°C oil bath and stir for 10h, then Cool to room temperature, filter to remove insoluble matter, concentrate, add ethyl acetate, wash with water, dry over anhydrous sodium sulfate, filter, and concentrate to obtain the brominated product; under nitrogen protection, dissolve the brominated product in 93 mL of anhydrous tetrahydrofuran, Add anhydrous tetrahydrofuran solution of potassium tert-butoxide (75.0g potassium tert-butoxide dissolved in 271mL anhydrous tetrahydrofuran), then react at room temperature for 7h, add water to extract the resulting mixed system twice, then add ethyl acetate to extract twice , combined organic layers, washed with water, dried over anhydrous sodium sulfate, filtered, and concentrated to obtain the unsaturated vegetable oil with increased double bonds; after mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com