A kind of bifunctional epoxy resin emulsifier and preparation method of emulsion

An epoxy resin and bifunctional technology, which is used in the field of preparation of bifunctional epoxy resin emulsifiers and emulsions, can solve the problems of difficult reaction control, high preparation cost, and many by-products, and achieves dilution and storage stability. Excellent, low reaction requirements, enhanced hydrophilicity and heat resistance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Synthesis of PEGDET

[0028] Under a nitrogen atmosphere, add 40.00g (10mmol) PEG4000 and 3.84g (20mmol) TMA to a 250ml three-neck flask with a condenser, heat and stir to make the raw materials completely miscible, and take 1ml (3.5mol / L) of TMA with a syringe. The boron trifluoride ether polyethylene glycol 400 solution was slowly added dropwise to the above reaction solution, the temperature was raised to 70°C, the acid value was measured every 0.5h, and the corresponding esterification rate was calculated, and the reaction was carried out for 2h. Then add 9.09g (20mmol) E-44 to the reaction system, continue the reaction at 95°C for 5h under the action of the catalyst boron trifluoride ether (no need to supplement), and take samples every 0.5h to measure the epoxy value to calculate the epoxy conversion rate , and finally make PEGDET.

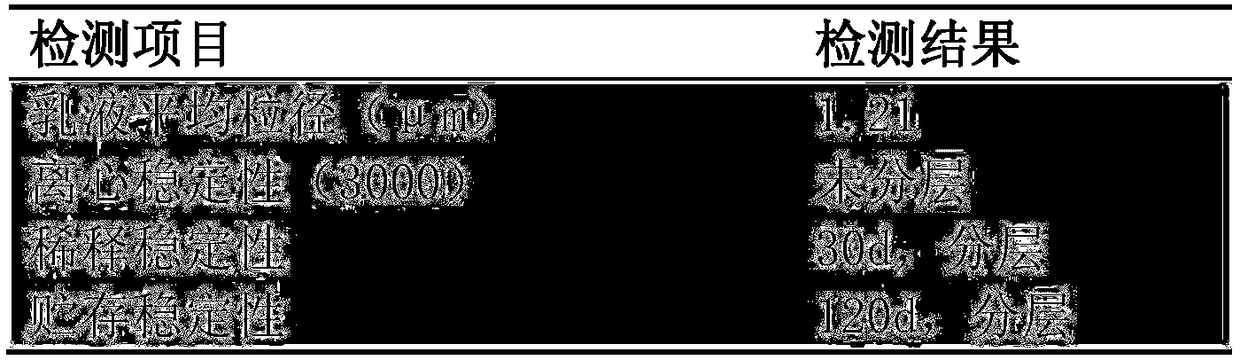

[0029] 2. Preparation of Waterborne Epoxy Resin Emulsion

[0030] Add the PEGDET and E-44 prepared by the above method into a 1...

Embodiment 2

[0033] 1. Synthesis of PEGDET

[0034] Under a nitrogen atmosphere, add 40.00g (10mmol) PEG4000 and 3.84g (20mmol) TMA to a 250ml three-necked flask with a condenser, heat and stir to make the raw materials completely miscible, and take 2ml (3.5mol / L) of TMA with a syringe. Boron trifluoride ether polyethylene glycol 400 solution was slowly added dropwise to the above reaction solution, the temperature was raised to 80°C, the acid value was measured every 0.5h, and the corresponding esterification rate was calculated, and the reaction was carried out for 2h. Then add 9.09g (20mmol) E-44 to the reaction system, continue the reaction at 95°C for 5h under the action of the catalyst boron trifluoride ether (no need to supplement), and take samples every 0.5h to measure the epoxy value to calculate the epoxy conversion rate , and finally make PEGDET.

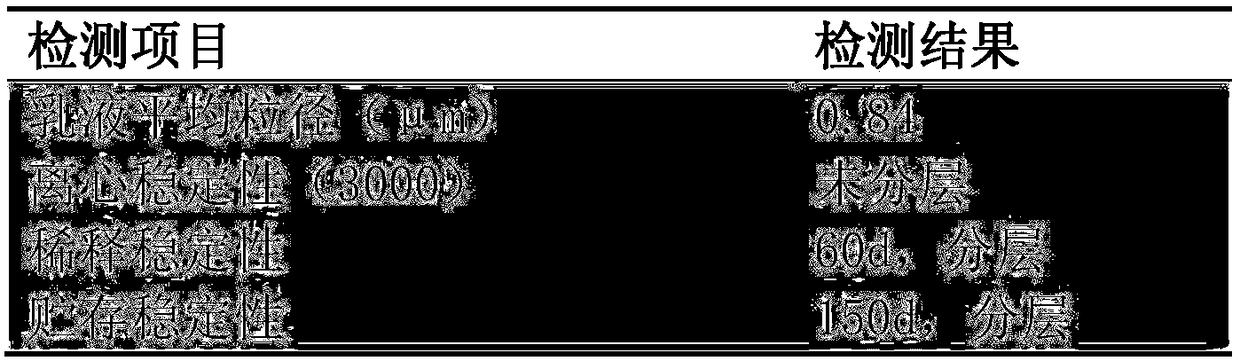

[0035] 2. Preparation of Waterborne Epoxy Resin Emulsion

[0036] Add the PEGDET and E-44 prepared by the above method into a 100...

Embodiment 3

[0039] 1. Synthesis of PEGDET

[0040] Under a nitrogen atmosphere, add 40.00g (10mmol) PEG4000 and 3.84g (20mmol) TMA to a 250ml three-necked flask with a condenser, heat and stir to make the raw materials completely miscible, and take 2ml (3.5mol / L) of TMA with a syringe. The boron trifluoride ether polyethylene glycol 400 solution was slowly added dropwise to the above reaction solution, the temperature was raised to 70°C, the acid value was measured every 0.5h, and the corresponding esterification rate was calculated, and the reaction was carried out for 1h. Then add 9.09g (20mmol) E-44 to the reaction system, continue the reaction at 95°C for 5h under the action of the catalyst boron trifluoride ether (no need to supplement), and take samples every 0.5h to measure the epoxy value to calculate the epoxy conversion rate , and finally make PEGDET.

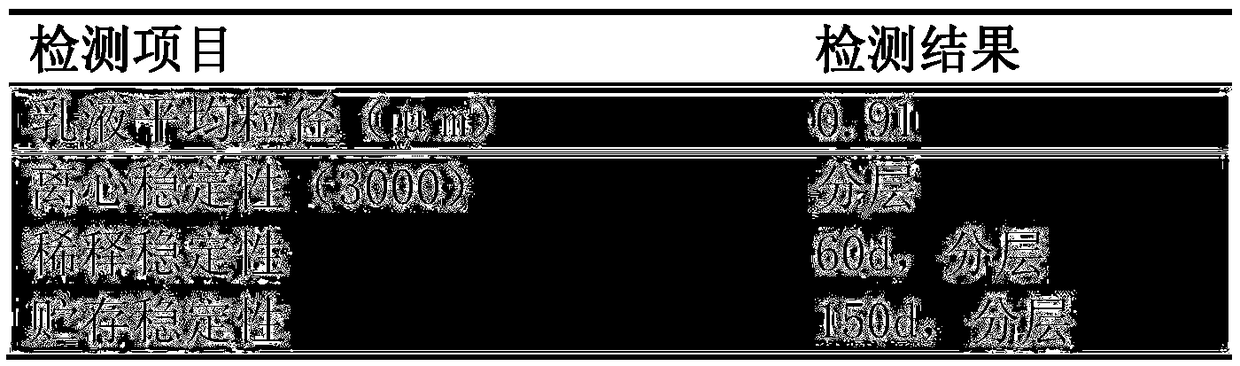

[0041] 2. Preparation of Waterborne Epoxy Resin Emulsion

[0042] Add the PEGDET and E-44 prepared by the above method into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com