Method for extracting phenolic compound in low-temperature coal tar by using ionic liquid

A technology for phenolic compounds and low-temperature coal tar, which is applied in the preparation of organic compounds, chemical instruments and methods, and tar processing by selective solvent extraction, can solve the problems of high processing cost, waste of resources, low extraction rate, etc. Low environmental pollution, easy operation and high phenol extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

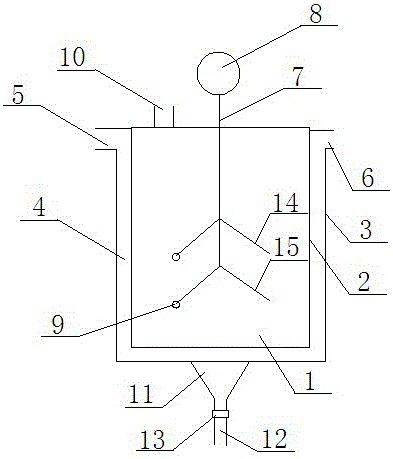

Image

Examples

Embodiment 1

[0021] Embodiment 1 A method of utilizing ionic liquid to extract phenolic compounds in medium and low temperature coal tar, the specific steps are:

[0022] (1) Measure 25 parts of medium and low temperature coal tar into the reaction kettle, then add 7 parts of monoethanolamine formic acid ionic liquid, heat in a water bath at 30°C, and stir for 30 minutes;

[0023] (2) The mixed solution obtained in step (1) (the mixed solution of medium-low temperature coal tar and monoethanolamine formic acid ionic liquid) was left to stand for 30 minutes to separate the two phases and transfer the lower layer to another container. Add 15 parts of diethyl ether into the container, stir at 25°C for 30 minutes, then let stand until the mixture is completely separated, and the obtained lower layer is a mixture of diethyl ether and phenolic compounds;

[0024] (3) Distill the ether in the mixture of ether and phenolic compounds at 45°C to obtain phenolic compounds.

[0025] After testing, th...

Embodiment 2

[0026] Embodiment 2 A method of utilizing ionic liquid to extract phenolic compounds in medium and low temperature coal tar, the specific steps are:

[0027] (1) Measure 28 parts of medium and low temperature coal tar into the reaction kettle, then add 9 parts of monoethanolamine formic acid ionic liquid, heat in a water bath at 34°C, and stir for 30 minutes;

[0028] (2) The mixed solution obtained in step (1) (the mixed solution of medium-low temperature coal tar and monoethanolamine formic acid ionic liquid) was left to stand for 30 minutes to separate the two phases and transfer the lower layer to another container. Add 18 parts of diethyl ether into the container, stir at 25°C for 30 minutes, then let it stand until the mixture is completely separated, and the obtained lower layer liquid is a mixture of diethyl ether and phenolic compounds;

[0029] (3) Distill the ether in the mixture of ether and phenolic compounds at 45°C to obtain phenolic compounds.

[0030] After t...

Embodiment 3

[0031] Embodiment 3 A kind of method utilizing ionic liquid to extract the phenolic compound in medium and low temperature coal tar, concrete steps are:

[0032] (1) Measure 21 parts of medium and low temperature coal tar into the reaction kettle, then add 5 parts of monoethanolamine formic acid ionic liquid, heat in a water bath at 27°C, and stir for 30 minutes;

[0033] (2) The mixed solution obtained in step (1) (mixed solution of medium-low temperature coal tar and monoethanolamine formic acid ionic liquid) was left to stand for 30 minutes to separate the two phases and transfer the lower layer to another container. Add 11 parts of diethyl ether to the container, stir at 25°C for 30 minutes, and then let it stand until the mixture is completely separated. The obtained lower layer liquid is a mixture of diethyl ether and phenolic compounds;

[0034] (3) Distill the ether in the mixture of ether and phenolic compounds at 45°C to obtain phenolic compounds.

[0035] After tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com