A kind of preparation method of microporous, high-porosity nickel-chromium-molybdenum porous material

A porous material and high porosity technology, applied in the field of porous metal material development, can solve the problems of small porosity, reduced temperature and corrosion resistance of nickel-based metal porous materials, and difficulty in meeting performance requirements, and achieves small pore size and high use. Harsh environmental conditions, easy and convenient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

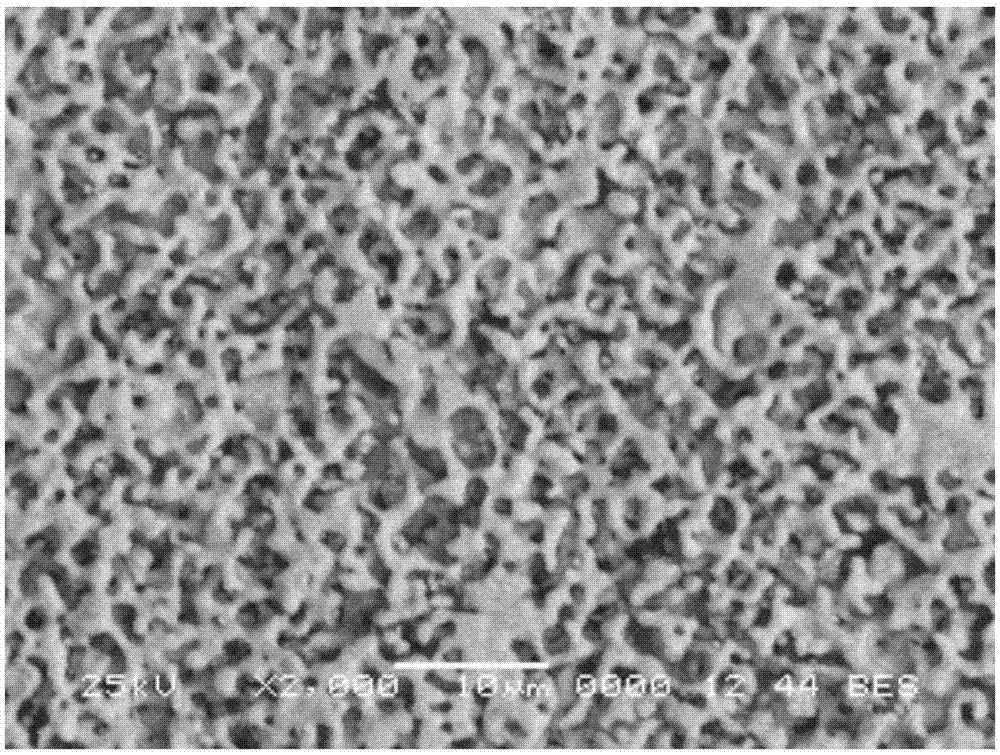

[0033] A nickel-chromium-molybdenum porous material with micropore size and high porosity was prepared, including: 40 nickel powder, 12 chromium powder, 4 molybdenum powder, 40 potassium phosphate, and 4 paraffin powder.

[0034]The preparation process includes the following steps: putting the weighed nickel powder, chromium powder and molybdenum powder into a ball mill container, putting hard alloy balls as ball mills, adding ethanol as a dispersion medium, and making the solvent and The material is fully wetted, according to the process parameters: the ratio of ball to material is 12:1, the speed is 220 rpm, and the time is 36 hours to obtain a uniform mixture with an average particle size of 3-4μm; the mixture is dried in a drying oven at 50°C for 3 hours Dry to obtain a fully dried nickel-chromium-molybdenum mixture. Add materials potassium phosphate powder 40 and paraffin powder 4 into the dry nickel-chromium-molybdenum mixture, put them into the ball mill container, put ...

Embodiment 2

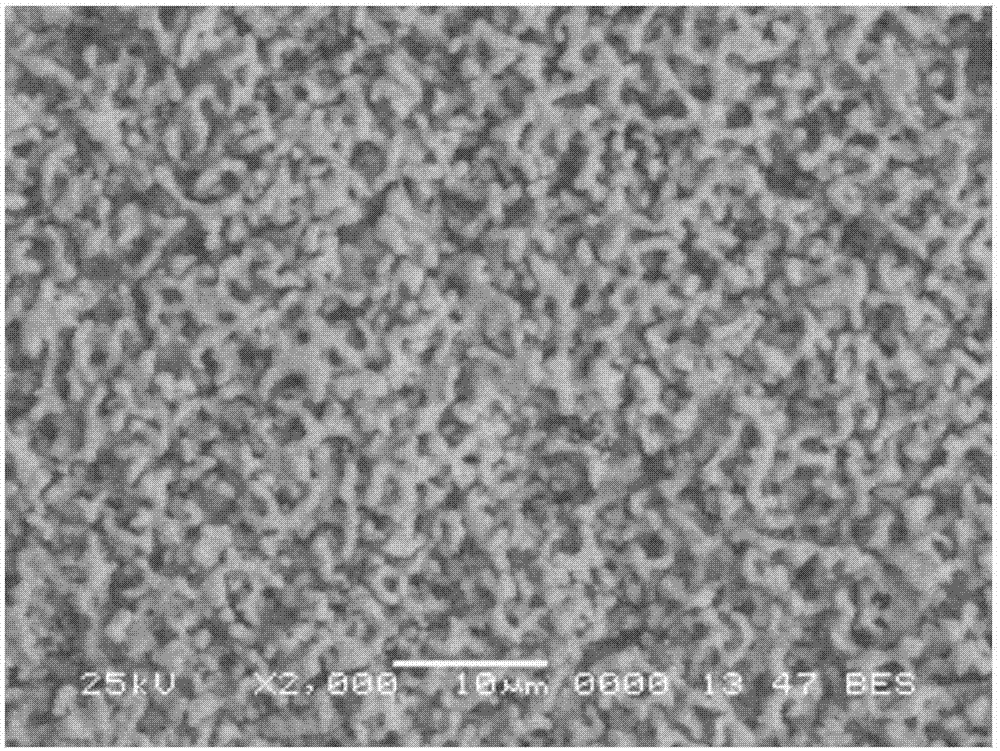

[0037] A nickel-chromium-molybdenum porous material with micropore size and high porosity was prepared, including: 44 nickel powders, 12 chromium powders, 5 molybdenum powders, 36 potassium phosphates, and 3 paraffin powders.

[0038] The preparation process includes the following steps: putting the weighed nickel powder, chromium powder and molybdenum powder into a ball mill container, putting hard alloy balls as ball mills, adding ethanol as a dispersion medium, and making the solvent and The material is fully wetted, according to the process parameters: the ratio of ball to material is 15:1, the rotation speed is 240 rpm, and the time is 48 hours, to obtain a uniform mixture with an average particle size of 1-2 μm; the mixture is dried in a drying oven at 60°C for 4 hours Dry to obtain a fully dried nickel-chromium-molybdenum mixture. Add materials potassium phosphate powder 36 and paraffin powder 3 into the dry nickel-chromium-molybdenum mixture, put them into a ball mill ...

Embodiment 3

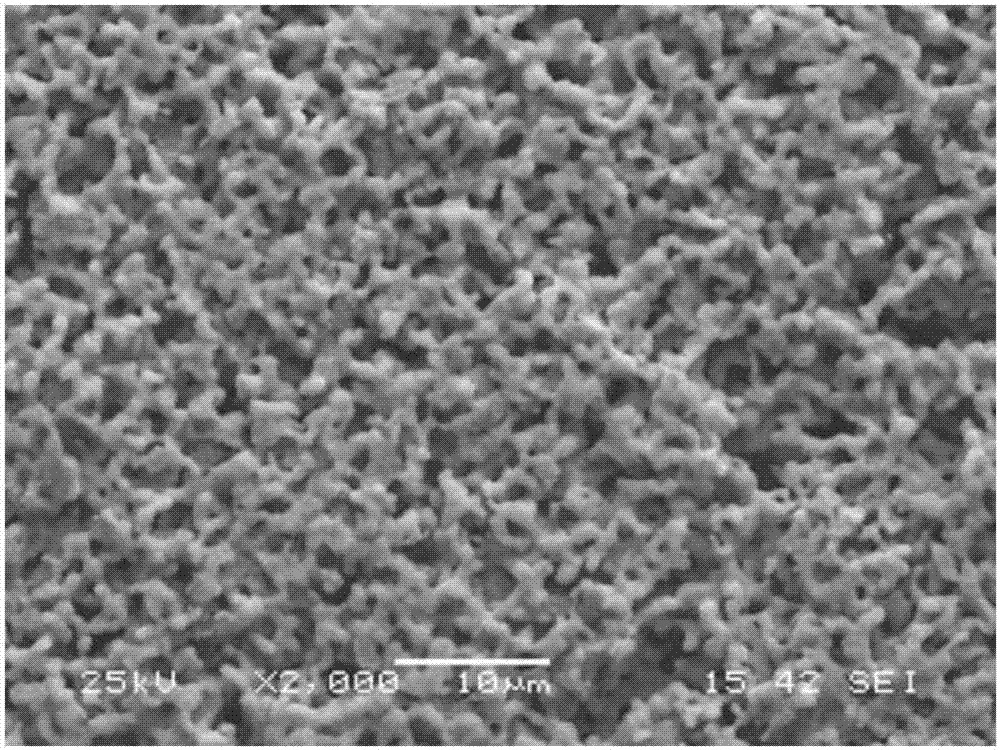

[0041] A nickel-chromium-molybdenum porous material with micropore size and high porosity was prepared, including: nickel powder 47, chromium powder 14, molybdenum powder 7, potassium phosphate 30, and paraffin powder 2.

[0042] The preparation process includes the following steps: putting the weighed nickel powder, chromium powder and molybdenum powder into a ball mill container, putting hard alloy balls as ball mills, adding ethanol as a dispersion medium, and making the solvent and The material is fully wetted, according to the process parameters: the ratio of ball to material is 10:1, the speed is 180 rpm, and the time is 24 hours, to obtain a uniform mixture with an average particle size of 4-5μm; the mixture is dried in a drying oven at 40°C for 2 hours Dry to obtain a fully dried nickel-chromium-molybdenum mixture. Add materials potassium phosphate powder 30 and paraffin powder 2 to the dry nickel-chromium-molybdenum mixture, put them into the ball mill container, put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com