Melting flaking method of copper concentrate for X-ray fluorescent spectrometry

A fluorescence spectrometry, copper concentrate technology, used in the preparation of test samples, material analysis using wave/particle radiation, measurement devices, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

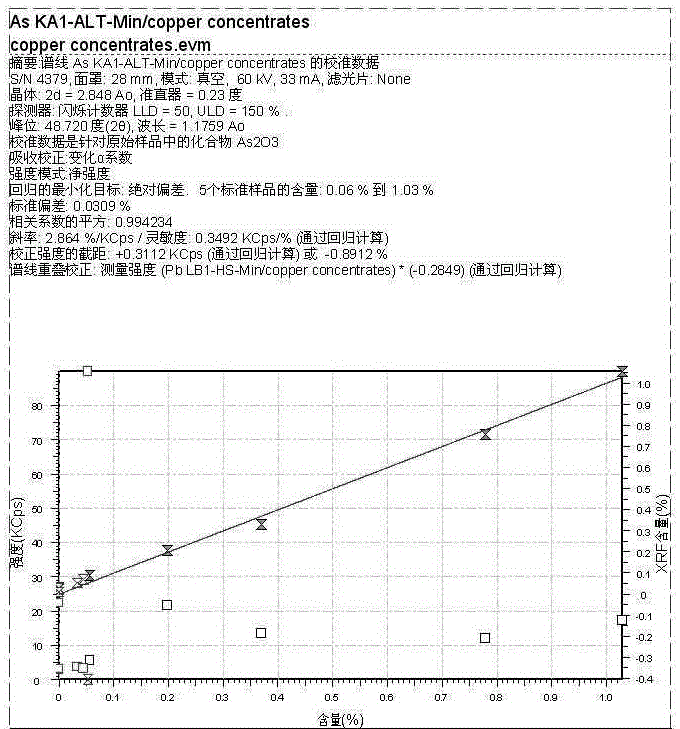

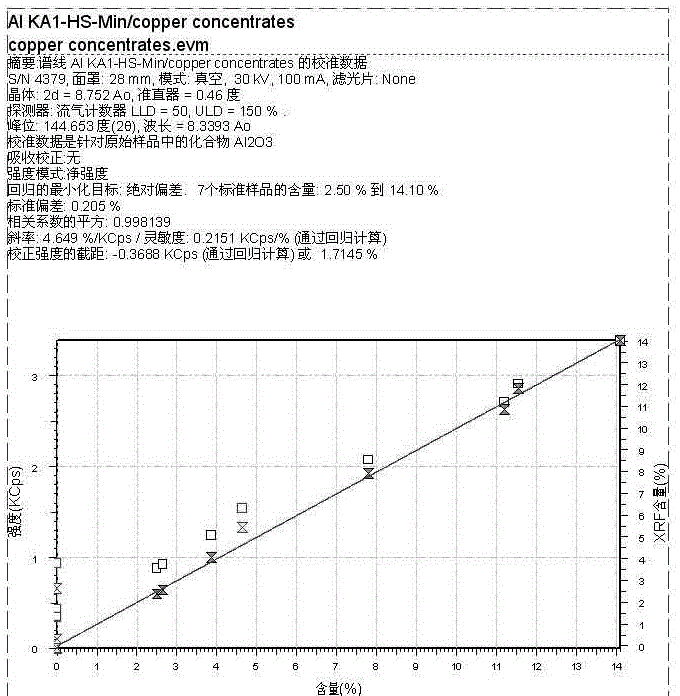

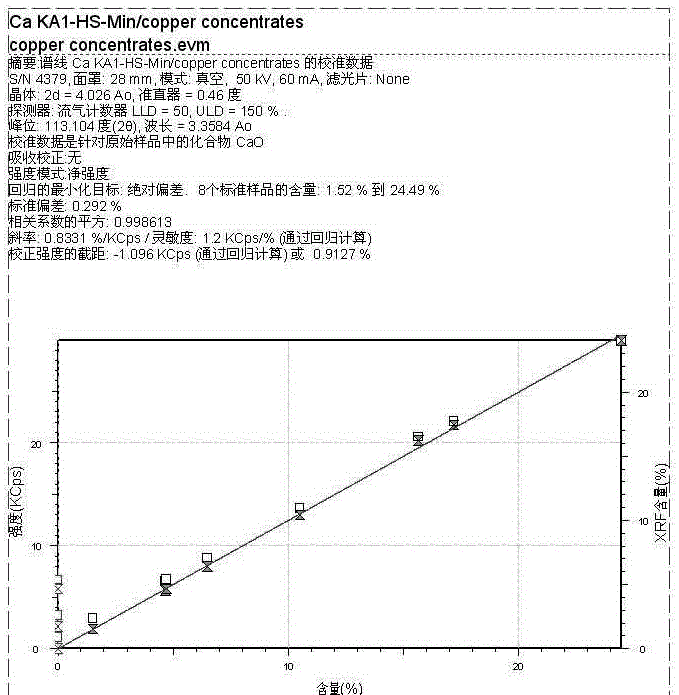

Image

Examples

Embodiment Construction

[0011] (1) Weigh 3.9 grams of lithium tetraborate and lithium metaborate (mass ratio of lithium tetraborate: lithium metaborate is 12:22) mixed flux in a platinum crucible, and spread the surface; weigh 1.06 grams of sodium carbonate, 0.38 gram of silicon dioxide, 1.5 gram of lithium nitrate, 0.1 gram of copper concentrate sample, stir gently with a paperclip, mix sodium carbonate, silicon dioxide, lithium nitrate and copper concentrate sample in the upper layer of the mixed flux; weigh 3.0 grams The mixed flux described above covers the sample mixture. Place the crucible in a muffle furnace at 600°C for 15 minutes, take it out, melt it in a melting furnace at 800°C, add 0.1 g of ammonium iodide and shake well, pour the molten material into a mold, and take out the formed glass piece for testing after cooling .

[0012] (2) Weigh 3.9 grams of lithium tetraborate and lithium metaborate (mass ratio of lithium tetraborate: lithium metaborate is 12:22) mixed flux in a platinum cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com