Flexible cnts/metal nanowire composite transparent conductive film, its preparation method and application

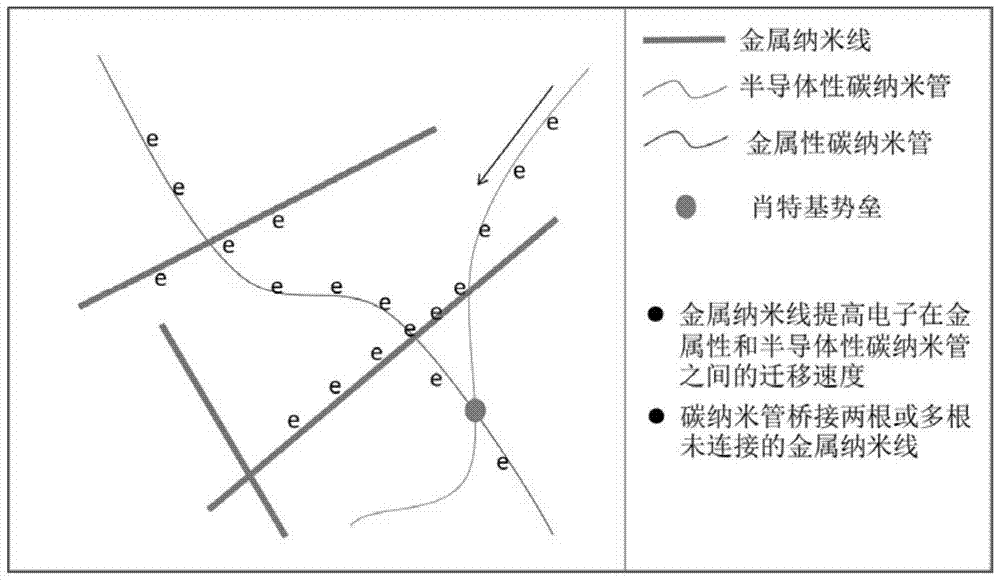

A metal nanowire, transparent conductive film technology, applied in cable/conductor manufacturing, nanotechnology, nanotechnology, etc., can solve the problem of inability to solve the adhesion of graphene films, affect the contact resistance of metal nanowires, and affect the photoelectric properties of composite films, etc. problem, to achieve the effect of being conducive to large-scale industrial production, improving the migration speed, and ensuring the stability of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

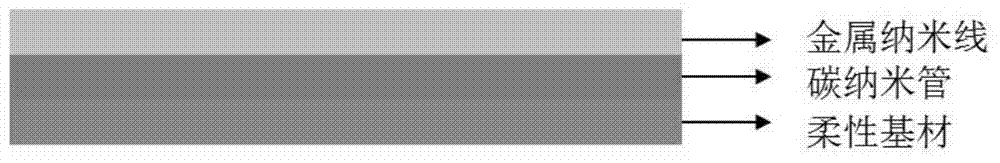

Embodiment 1

[0044] a) Coat 5mg / mL silver nanowire conductive ink on the coated surface of PET transparent substrate with No. 12 wire rod, and dry at 100°C for 2min. The surface resistance of the silver nanowire film is 430ohm / sq, and the light transmittance is 90.8 % (if not specified below, all refer to the light transmittance of visible light), the haze is 1.5%, wherein the diameter of silver nanowires is about 40nm, and the length is about 20μm. components;

[0045] b) preparing a single-walled carbon nanotube conductive film on a metal flexible substrate by CVD;

[0046] c) transfer the single-walled carbon nanotube conductive film on the metal flexible substrate to the surface of the silver nanowire conductive film in a roll-to-roll form to prepare a silver nanowire / carbon nanotube composite conductive film (refer to CN103031531A, etc.);

[0047] d) The obtained composite transparent conductive film has a surface resistance of 150 ohm / sq, a light transmittance of 89.2%, and a haze of ...

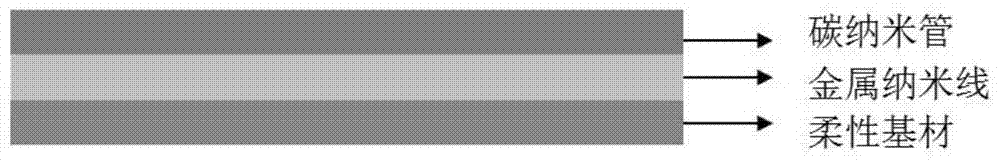

Embodiment 2

[0049] a) growing a single-walled carbon nanotube conductive film on a metal flexible substrate by CVD;

[0050] b) The single-walled carbon nanotube conductive film grown on the metal flexible substrate is transferred to the coated surface of the PET transparent substrate in the form of roll-to-roll, and the surface resistance of the prepared single-walled carbon nanotube conductive film is 900ohm / sq;

[0051] c) 5 mg / mL silver nanowire conductive ink is coated on the surface of the single-walled carbon nanotube conductive film with a No. 12 wire rod, and dried at 100° C. for 2 minutes to prepare a carbon nanotube / silver nanowire composite conductive film (refer to CN103031531A, etc.), Wherein the silver nanowire has a diameter of 30nm and a length of 25 μm, and the conductive ink can also include suitable components known in the industry such as dispersants and resins;

[0052] d) The obtained composite transparent conductive film has a surface resistance of 120 ohm / sq and...

Embodiment 3

[0054] a) transfer PET substrate coating surface with 1mg / mL single-wall carbon nanotube dispersion liquid through suction filtration to make single-wall carbon nanotube conductive film, the surface square resistance of the prepared single-wall carbon nanotube conductive film is 2000ohm / sq (refer to CN102602118A, CN102110489B, etc.);

[0055] b) Apply 5 mg / mL silver nanowire conductive ink to the surface of the single-walled carbon nanotube conductive film with a No. 12 wire rod, and dry it at 100°C for 2 minutes. The surface square resistance of the carbon nanotube / silver nanowire composite conductive film is 215ohm. / sq, wherein the silver nanowires have a diameter of 30nm and a length of 30 μm, and the conductive ink can also include suitable components known in the industry such as dispersants and resins;

[0056] c) preparing a single-walled carbon nanotube conductive film on a metal flexible substrate by CVD;

[0057] d) The single-walled carbon nanotube conductive fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com