A flexible photoelectric sensor based on three-dimensional conformal graphene and its manufacturing method

A photoelectric sensor and graphene technology, applied in the field of sensors, can solve the problems of complex sensor structure, poor, non-flexible biocompatibility, etc., and achieve good biocompatibility, convenient processing, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

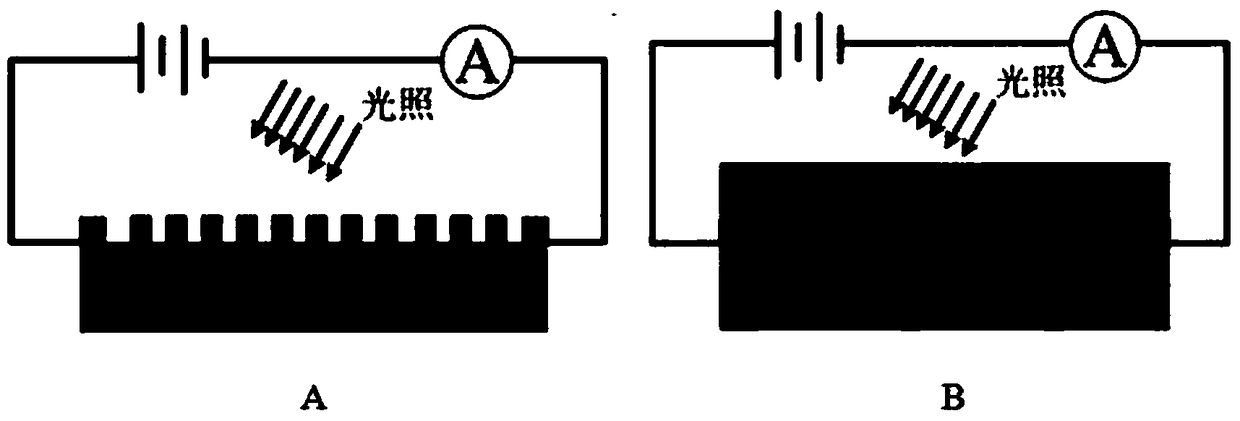

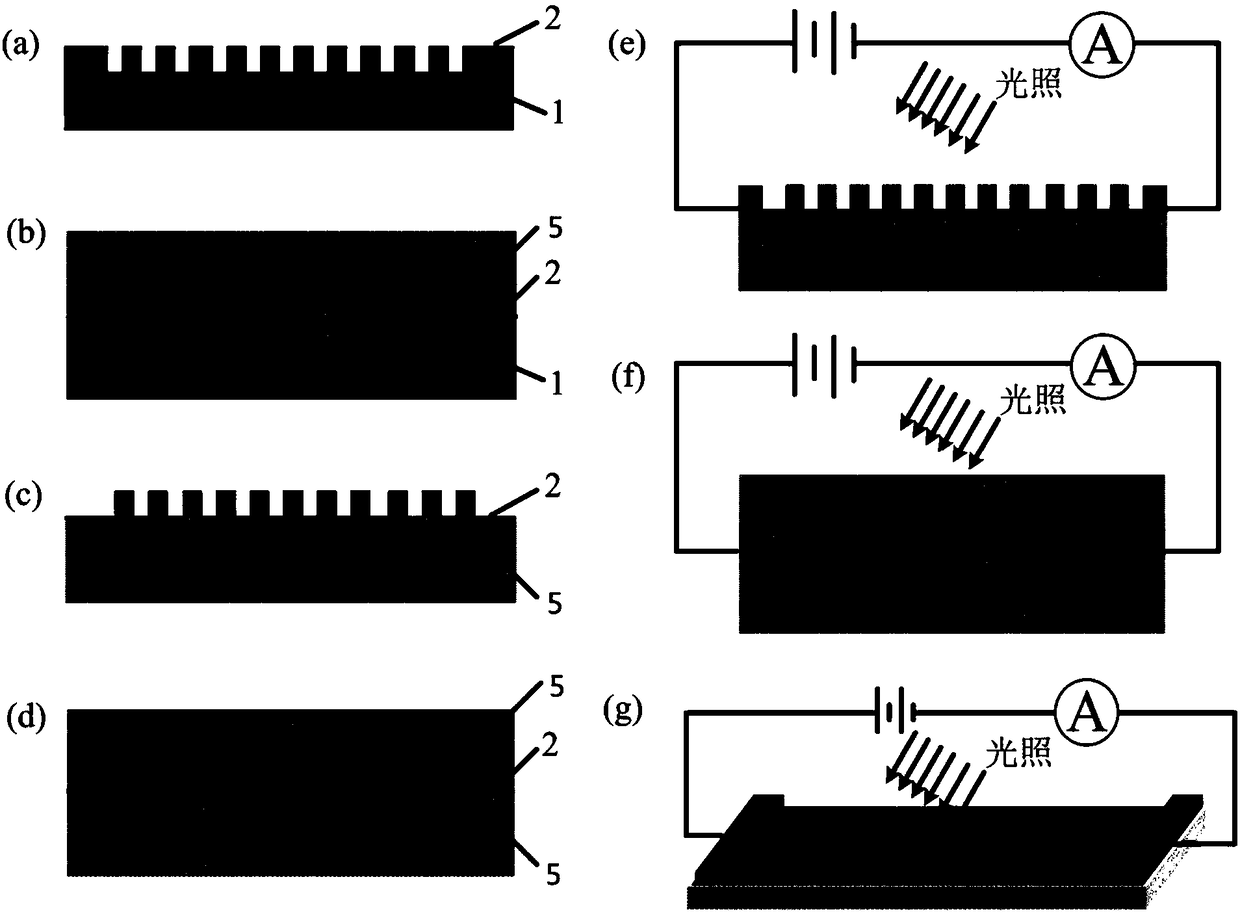

[0054] Example 2: Fabrication of "PDMS / 3D Conformal Graphene / PDMS" Composite Photoelectric Sensor and Testing of Its Sensing Characteristics

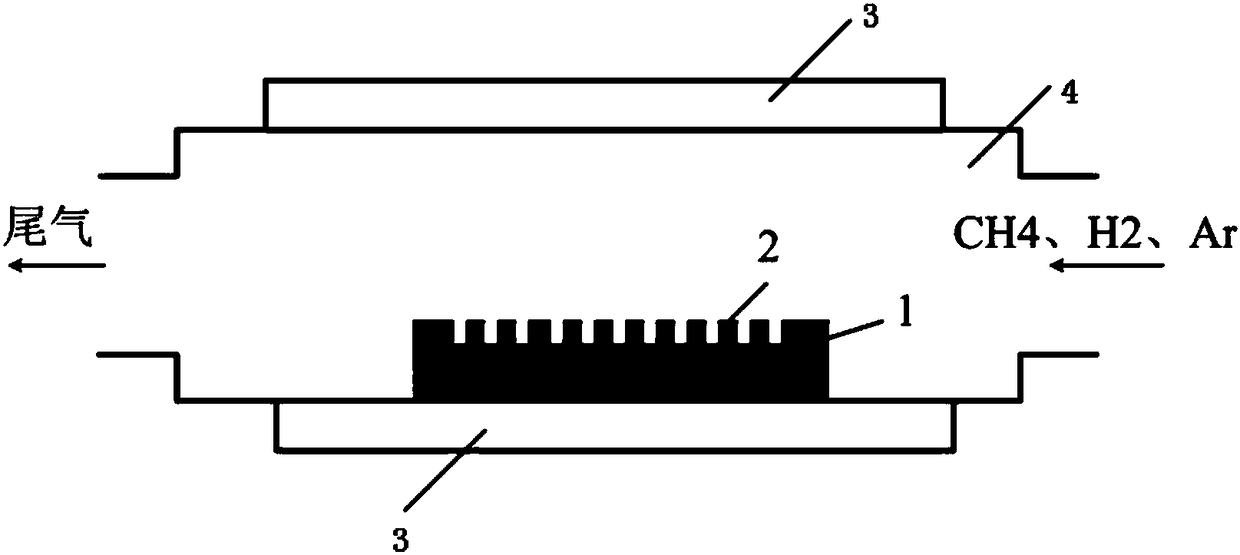

[0055] Step 1: Preparation of 3D conformal graphene

[0056] First place the substrate copper foil in acetone, 95vol% ethanol, and pure water for ultrasonic cleaning for 10-15 minutes, blow dry with nitrogen, and then prepare a microscopic surface structure with a three-dimensional inverted pyramid array by photolithography and wet etching. Silicon wafer substrate;

[0057] Then place the above-mentioned silicon chip substrate with the microscopic surface structure of three-dimensional inverted pyramid array in acetone, 95vol% ethanol, and pure water for ultrasonic cleaning for 10-15 minutes, blow dry with nitrogen, and then place it in the vacuum chamber of the tube furnace CVD system In vivo preparation of three-dimensional conformal graphene (such as figure 1 shown), to obtain "three-dimensional conformal graphene / silicon chip subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com