Preparation method of ultrathin B phase titanium dioxide nano sheet

A titanium dioxide and nanosheet technology, applied in the directions of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of high output of waste by-products, difficult production, large amount of sulfuric acid, etc., and achieve the output of waste by-products. Less, good application value, mild synthesis and post-treatment conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) In an open beaker, add 1 mL of titanium tetrachloride to 30 mL of ethylene glycol, and stir for 10 minutes to obtain a titanium glycolate solution.

[0028] (2) Add 1 mL of water into the titanium ethylene glycol solution prepared in step (1), stir for 10 min, transfer the resulting solution to a reaction kettle, react at 150° C. for 4 h, and then centrifuge the resulting suspension.

[0029] (3) Wash the white precipitate obtained in step (2) with water and ethanol for 3 times, then dry naturally to obtain the target product.

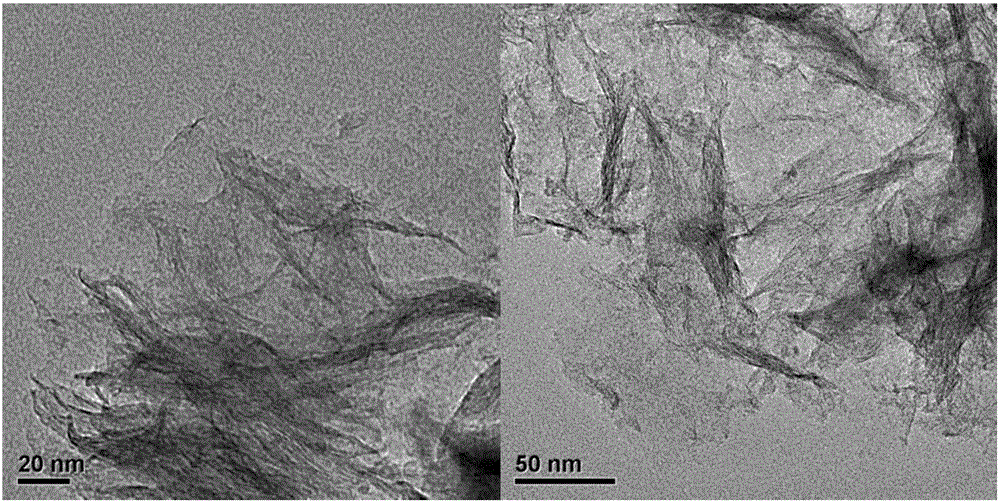

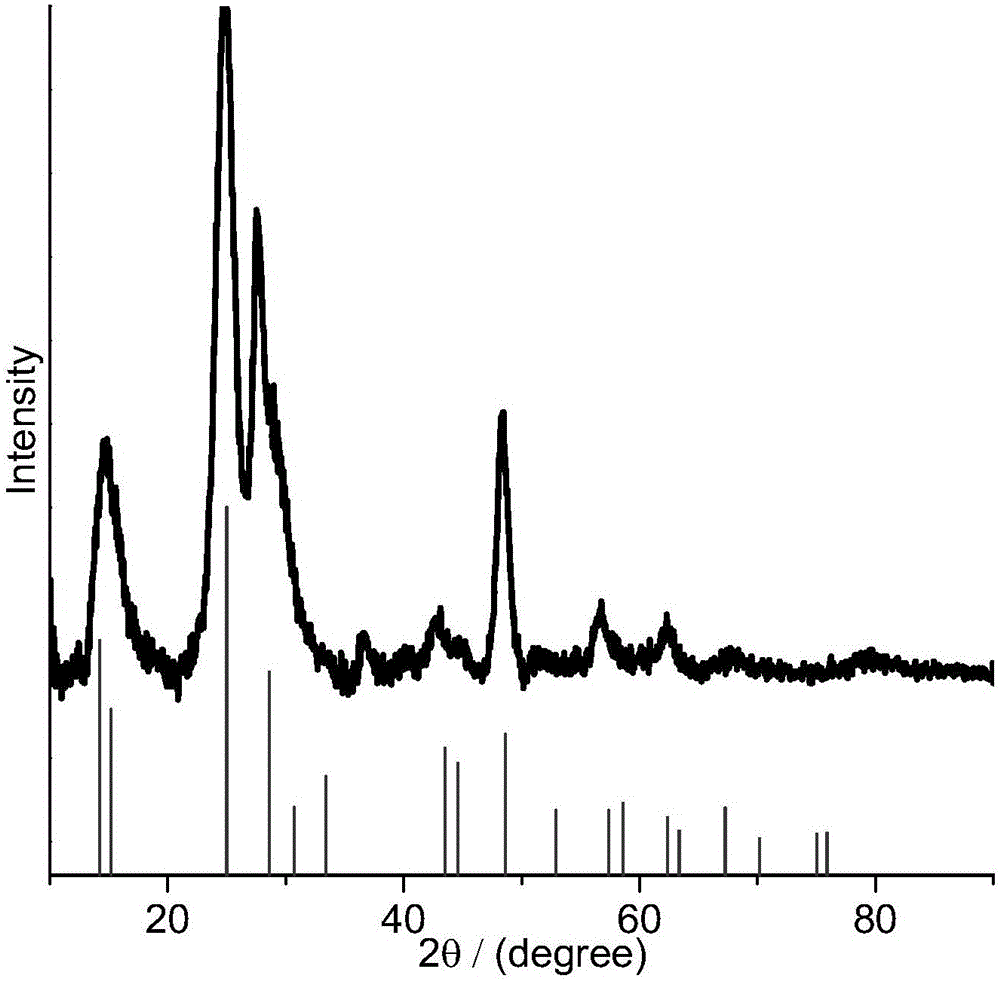

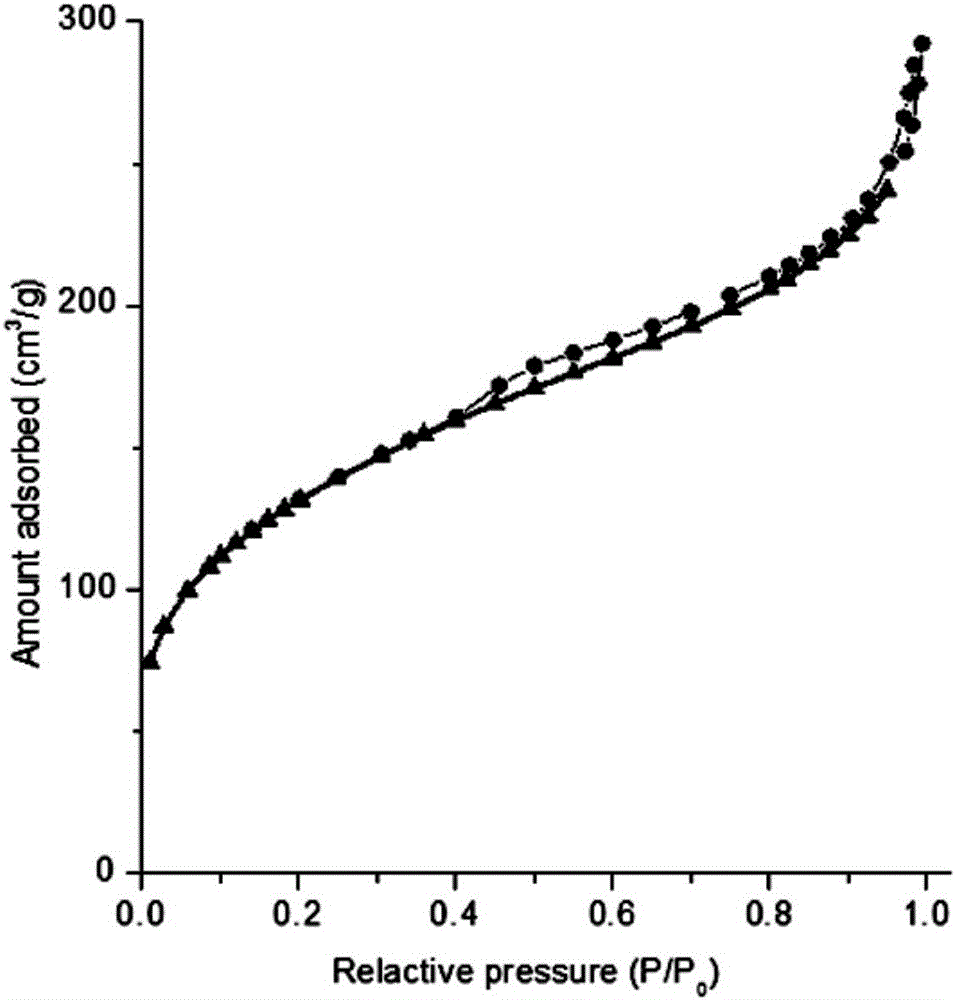

[0030] Depend on figure 1 It can be seen that the prepared ultra-thin titanium dioxide has a typical two-dimensional material structure. Depend on figure 2 It can be seen that the X-ray diffraction pattern of the obtained ultrathin TiO2 powder indicates its unique B-phase structure. Nitrogen adsorption curve based on ultrathin titanium dioxide ( image 3 ), it can be seen that the ultra-thin titanium dioxide has the adsorption behavior ...

Embodiment 2

[0032] (1) In an open beaker, add 3 mL of titanium tetrachloride to 30 mL of ethylene glycol, and stir for 10 minutes to obtain a titanium glycolate solution.

[0033] (2) Add 3 mL of water into the titanium ethylene glycol solution prepared in step (1), stir for 10 min, transfer the resulting solution to a flask, react at 150° C. for 4 h, and then centrifuge the resulting suspension.

[0034] (3) Wash the white precipitate obtained in step (2) with water and ethanol for 3 times, then dry naturally to obtain the target product.

Embodiment 3

[0036] (1) In an open beaker, add 1 mL of titanium tetrachloride to 30 mL of ethylene glycol, and stir for 10 minutes to obtain a titanium glycolate solution.

[0037] (2) Add 1 mL of water into the titanium ethylene glycol solution prepared in step (1), stir for 10 min, transfer the resulting solution to a flask, react at 160° C. for 4 h, and then centrifuge the resulting suspension.

[0038] (3) Wash the white precipitate obtained in step (2) with water and ethanol for 3 times, then dry naturally to obtain the target product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com