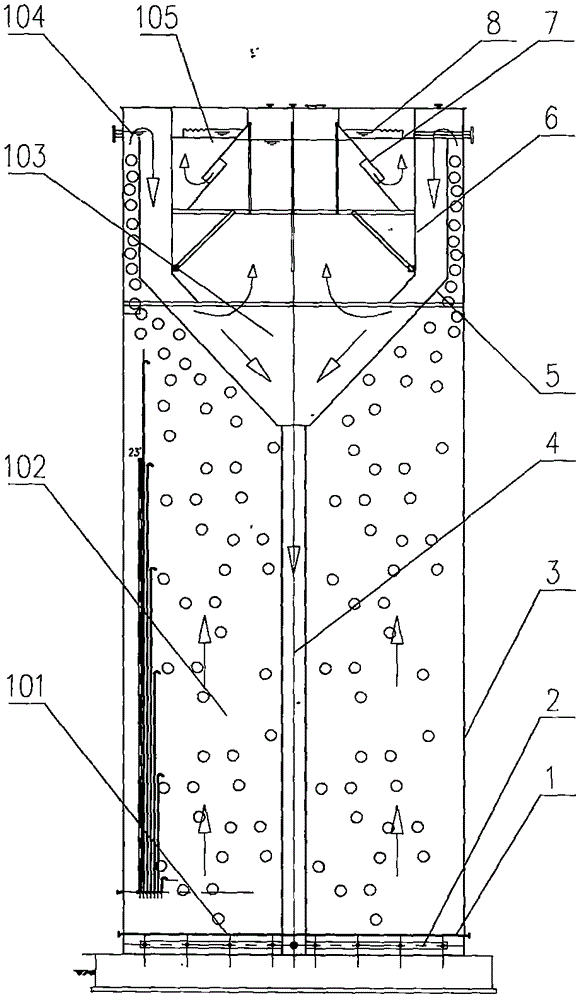

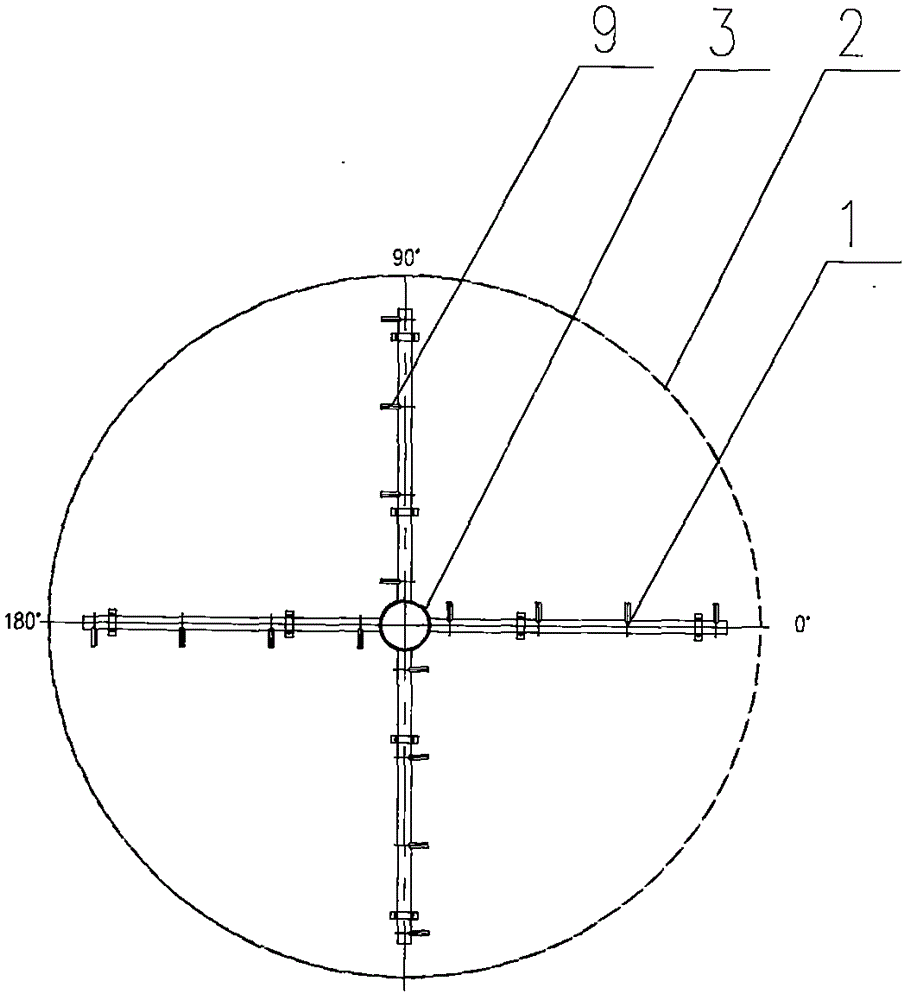

Self-circulation anaerobic reactor

An anaerobic reactor and self-circulation technology, applied in anaerobic digestion treatment, chemical instruments and methods, water treatment parameter control, etc., can solve the problems of consuming the effective volume of the reactor, poor uniformity of water distribution, and increased construction cost, etc. Achieve the effect of speeding up water purification rate, small equipment footprint, and reduced investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Biodiesel wastewater from a biomass energy company in Jiangsu, including workshop wastewater, the main pollutants are ethanol, isopropanol, etc.; raw material pool wastewater, the main pollutants are alcohol, ketone, etc.; boiler room wastewater, cleaning wastewater and domestic wastewater, the above After the wastewater is mixed, the volume of wastewater is 15m3 / h, CODcr is about 100,000mg / L, sulfate is 50,000mg / L, ammonia nitrogen is 50mg / L, and SS2000mg / L; pretreatment + two-stage anaerobic + two-stage aerobic + MBR process treatment , where the first stage anaerobic adopts this self-circulating anaerobic reactor After pretreatment and reflux, the water quality of the anaerobic reactor is about 30000mg / L for CODcr, 10000mg / L for sulfate, 50mg / L for ammonia nitrogen, and 1000mg / L for SS.

[0032] Process parameters during operation of this reactor:

[0033] Volume load: 15kgCOD / m3.d; influent COD concentration: 30000mg / L; COD removal rate: 70%; reactor height 22m.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com