Tower-type device for decomposing ethylene chloride and manufacturing method of key components thereof

A vinyl chloride, tower-type technology, applied in the field of sewage treatment equipment, can solve the problems that the natural environmental conditions of the oxidation-reduction potential are easily damaged, hinder the development and vigorous promotion of the permeable reaction wall, and the permeable reaction wall is easy to be blocked, etc. Achieve good market prospects, high environmental benefits and economic benefits, and a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

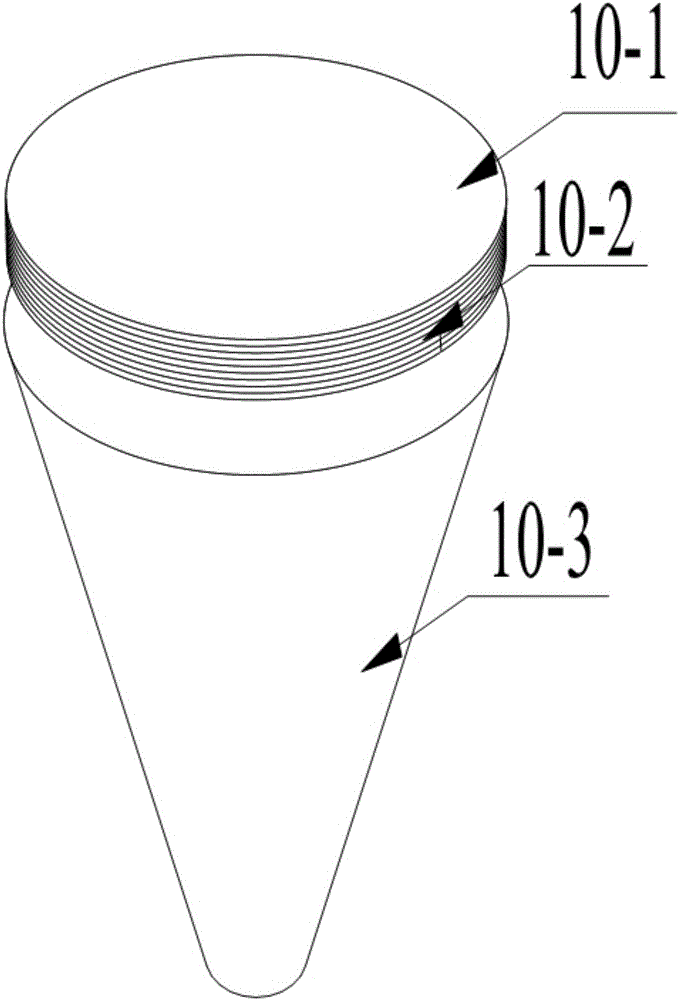

[0051] Prepare the ozone disinfection filter layer 10-2 of the present invention according to the following steps, and in parts by weight:

[0052] Step 1: In the batch reactor, add 222.805 parts of complete deionized water and 14..895 parts of C12-C14 fatty alcohol polyoxyethylene (2) ether sodium sulfate, start the mixer in the batch reactor, and set the speed at 15.595rpm, start the heating device in the batch reactor, raise the temperature to 30.421°C, add 17.447 parts of di-n-hexadecyl succinate, 13.443 parts of N-cyclohexyl p-toluenesulfonamide, and stir evenly to carry out ester oxidation The chemical reaction was 7.159 hours; after that, 16.406 parts of p-nitrosodiethylaniline and 19.457 parts of 1-hydroxyl-4-aminoanthraquinone were added in the batch reactor, and the pH value of the solution in the batch reactor was adjusted to 4.8192;

[0053] Step 2: Take another 16.27 parts of 2-hydroxyanthraquinone, 13.786 parts of 4-methoxybenzyl alcohol, and 21.939 parts of Ag n...

Embodiment 2

[0058] Prepare the ozone disinfection filter layer 10-2 of the present invention according to the following steps, and in parts by weight:

[0059] Step 1: In the batch reactor, add 447.999 parts of complete deionized water and 56.795 parts of C12-C14 fatty alcohol polyoxyethylene (2) ether sodium sulfate, start the mixer in the batch reactor, set the speed at 61.45rpm, Start the heating device in the batch reactor to raise the temperature to 31.407°C, add 126.901 parts of di-n-hexadecyl succinate and 30.398 parts of N-cyclohexyl p-toluenesulfonamide, and stir evenly to carry out oxidative esterification reaction 18.484 Hour; Add 73.945 parts of p-nitrosodiethylaniline and 80.937 parts of 1-hydroxyl-4-aminoanthraquinone in the batch reactor afterwards, adjust the pH value of the solution in the batch reactor to 8.9610;

[0060] Step 2: Take another 39.827 parts of 2-hydroxyanthraquinone, 58.72 parts of 4-methoxybenzyl alcohol, and 76.171 parts of Ag nanoparticles, pulverize an...

Embodiment 3

[0065] Prepare the ozone disinfection filter layer 10-2 of the present invention according to the following steps, and in parts by weight:

[0066] Step 1: In the batch reactor, add 223.805 parts of complete deionized water and 15.999 parts of C12-C14 fatty alcohol polyoxyethylene (2) ether sodium sulfate, start the mixer in the batch reactor, set the speed at 16.895rpm, Start the heating device in the batch reactor, raise the temperature to 31.795°C, add 18.447 parts of di-n-hexadecyl succinate, 14.901 parts of N-cyclohexyl p-toluenesulfonamide, and stir evenly to carry out oxidative esterification reaction 8.443 Hour; Add 17.398 parts of p-nitrosodiethylaniline and 20.406 parts of 1-hydroxyl-4-aminoanthraquinone in the batch reactor afterwards, adjust the pH range of the solution in the batch reactor to 5.4945;

[0067] Step 2: Take another 17.457 parts of 2-hydroxyanthraquinone, 14.937 parts of 4-methoxybenzyl alcohol, and 22.27 parts of Ag nanoparticles, pulverize and grin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com