Concrete rheological preservative as well as preparation method and application thereof

A technology of concrete and preservatives, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., to achieve the effects of reduced emptying time, improved compressive strength and corrosion resistance coefficient, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Preparation of concrete rheological preservative

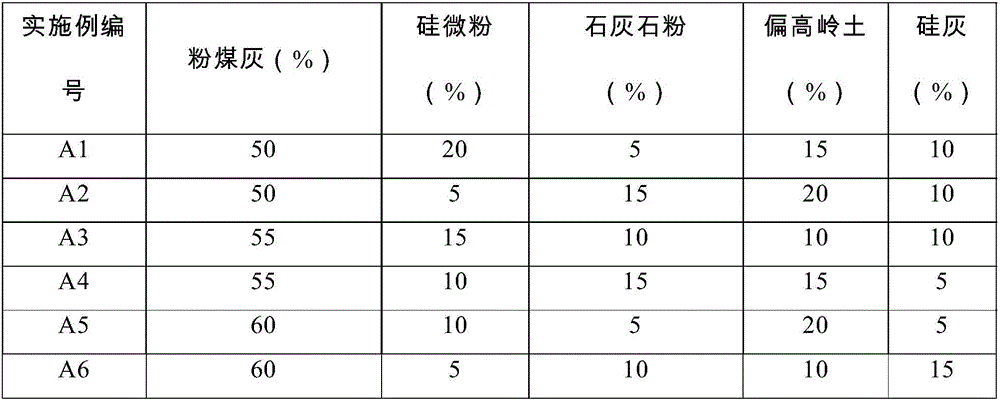

[0028] Put fly ash, silica micropowder, limestone powder, metakaolin, and silica fume into the mixing equipment according to the proportion, and stir evenly. The component content implemented by each component is shown in Table 1.

[0029] Wherein, the "fly ash" used in the examples is the fine ash collected from the flue gas after coal combustion. The fly ash used for the concrete rheological preservative of the present invention is Class I fly ash, and the specific surface area is 1197m 2 / kg, the water requirement is 89%.

[0030] The "silica powder" used is processed from pure quartz powder through advanced ultra-fine grinding process. The concrete rheological preservative of the present invention uses silicon micropowder, specific surface area is 1311m 2 / kg.

[0031] The "limestone powder" used is a powdery material that is ground to a specified fineness with limestone of a certain purity as th...

Embodiment 2

[0036] Embodiment 2: performance test and result

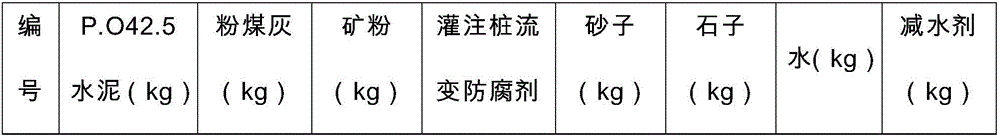

[0037] In order to verify the performance effect of the concrete rheological preservative of the present invention, the inventor selected concrete with a strength grade of C45 to test the performance of the concrete rheological preservatives A1-A6 prepared in the above examples. The ratio of C45 is shown in Table 2. In accordance with the "Technical Regulations for the Application of High Strength Concrete" JGJ / T281-2012, the emptying time test of the inverted slump cylinder was carried out, and the "Standard for Test Methods for Long-term Performance and Durability of Ordinary Concrete" GB / T50082-2009 was carried out for the sulfate corrosion resistance test and chlorine resistance. Ion penetration test, the performance test results are shown in Table 3.

[0038] Basic properties of concrete raw materials: cement is Jidong P.O42.5, fly ash is Class II fly ash, mineral powder is S95 grade mineral powder, sand is machine-made...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com